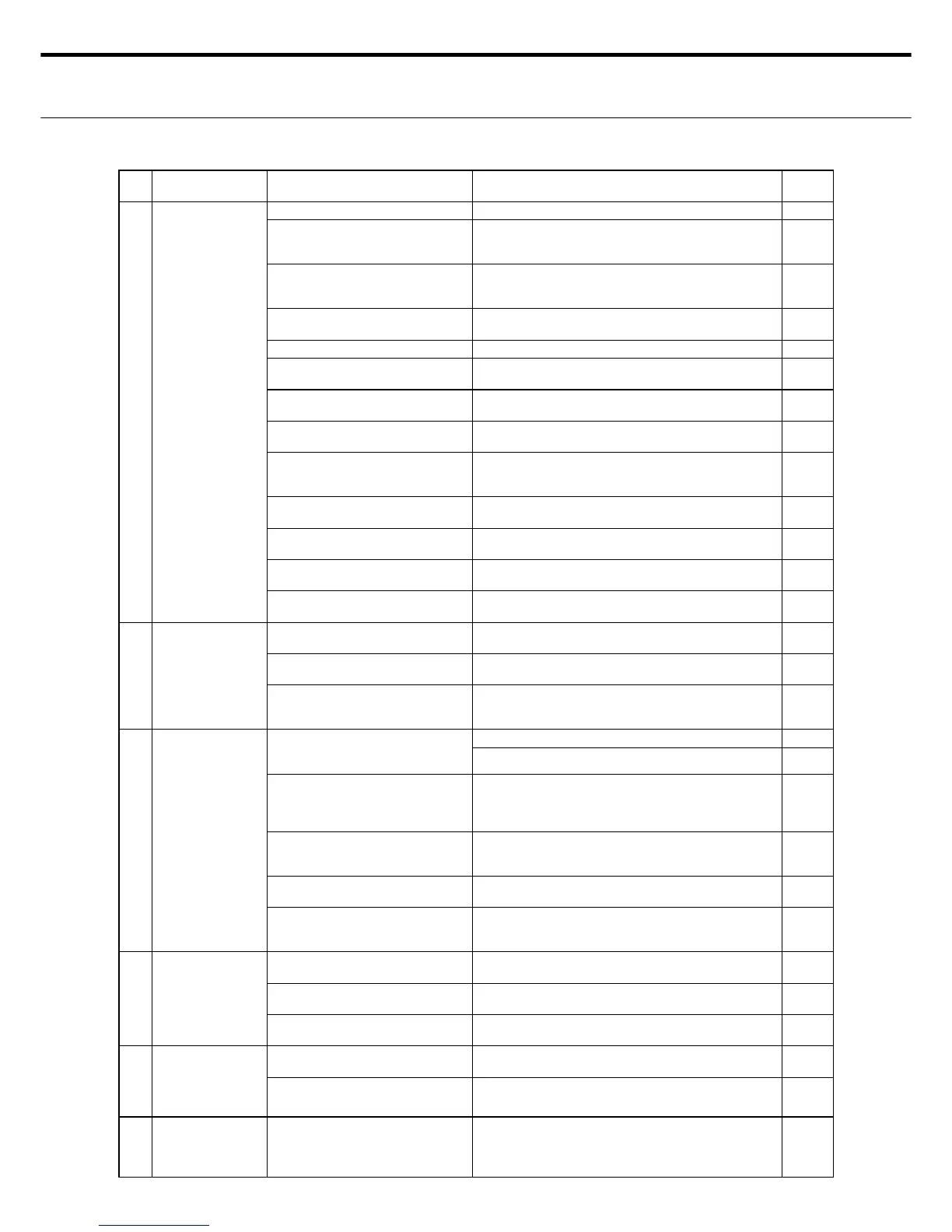

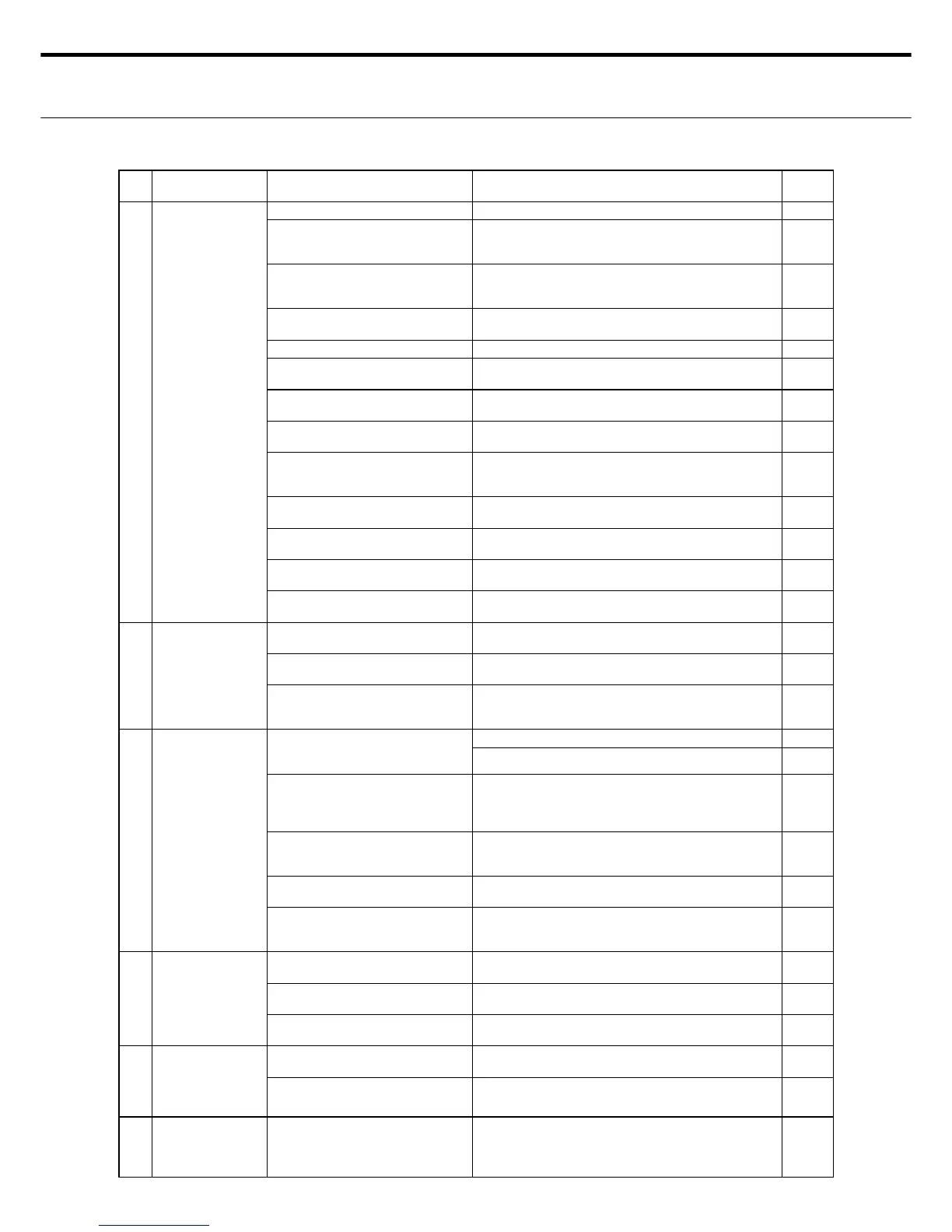

52

No. PROBLEM CHECKPOINT ACTION

SEE

PAGE

5 Jams keep occur-

ring

Is the paper set correctly? Set the paper correctly P20

Are the paper guides aligned

with the paper width?

If too narrow the paper is hard to feed and if too

wide the paper bends or twists. Set the guides too

match the paper width.

P20

Does the paper length set in the

cutting format match the length

of the paper set in the machine?

Set paper in the feed tray that matches the paper

length set in the cutting format.

P38

Does the currently used paper

have a curl in it?

Correct the curl in the paper. Set different paper in

the machine and check the paper feed operation.

-

Are there wrinkles in the paper? Do not use paper with wrinkles in it. -

Is paper residue or dirt on the

sensors?

Turn off the power and clean the machine P29

Is there any paper residue or dirt

on the suction belt or rollers?

Turn off the power and clean the machine. P29

Are any remaining paper scraps

jammed inside the machine?

Turn off the power, check the inside of the ma-

chine and remove any remaining paper scraps.

P25

How is the quality of the paper

you are using?

Check that factors such as the paper size and

thickness are correct. Set different paper in the

machine and check the paper feed operation.

P10

Is it being used in the correct en-

vironment?

Use in an environment of 10 to 32 , and humidity

of 20 to 80%RH.

P9

Is the paper that was set, the

wrong type?

Set only paper of the same type in the paper feed

unit.

-

Are static charges accumulating

in the paper?

See "Static charges on paper" and take counter-

measures to reduce static charges.

P49

Is cutting paper waste accumu-

lating inside the machine?

After turning off the power, open the top cover and

drop the cutting waste into the cutting waste box.

-

6 Paper is being

cut while bent

(askew).

Is the paper in the tray bent

(askew)?

Place the paper so it is aligned correctly in the

tray.

P20

Is there any paper residue or dirt

on the suction belt or rollers?

Turn off the power and clean the machine. P29

How is the quality of the paper

you are using?

Check that factors such as the paper size and

thickness are correct. Set different paper in the

machine and check the paper feed operation.

P10

7 Cut position is off

center (askew)

Is the paper correctly set?

Were fi ne adjustments made to

the cutting position?

Set the paper correctly in the paper feed tray. P20

Make fi ne adjustments to the cutting position. P24/38

Were the wrong settings made

for the cutting format or the

rotary blade mounted in the ma-

chine?

Check the settings for the cutting format and ro-

tary blade and correct if necessary.

P33

If the cutting position is set to

"Mark" are the cut mark specifi -

cations correct?

Use paper that matches the cut mark specifi ca-

tions.

P46

Is there dirt or grime on the pa-

per feed rubber rollers?

Turn off the power and clean the paper feed rub-

ber rollers.

P29

Is the printing tilted or out of po-

sition?

Correct the print deviation. Or adjust "Cut length",

the "trim length", "Lead edge margin" of the cutting

format according to how the print has deviated.

P40

P42

P44

8 Paper is not being

cut.

How is the quality of the paper

you are using?

Cutting might not be correct depending on the

quality of the paper.

-

Is the thickness of the paper

within the specifi ed range?

A cuttable paper thickness is 0.12 to 0.40mm. P10

Is the cutter being replaced at

regular intervals?

Both the rotary blade and long blade are subject

to wear. Replace them periodically.

P50

9 Message, "No

paper" appears

even though pa-

per is set in the

machine.

Does the paper being used have

a curl in it?

Correct the curl in the paper. P10

Is the paper set straight in the

tray?

Set the paper correctly in the paper feed tray. P20

10 Cutting in free

format is not sat-

isfactory.

Is the cutting format setup cor-

rect?

Caution points for the format setup are listed in

the "Cutting Format" in the appendix. So read that

information and then check if the cutting format

setup is correct.

Appendix

Loading...

Loading...