22 MPSYSTEMS-M-001/06

6.4. Low Pressure Installation

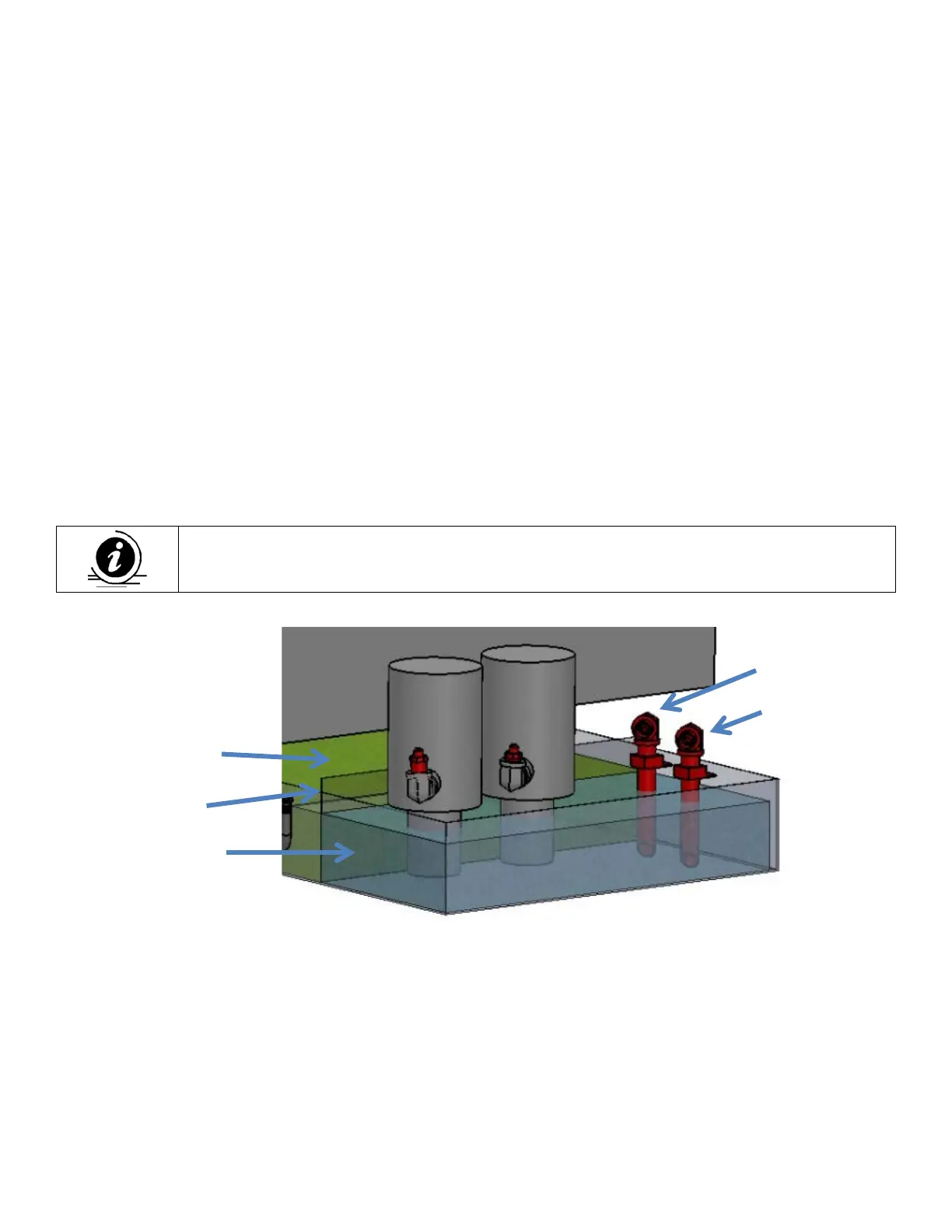

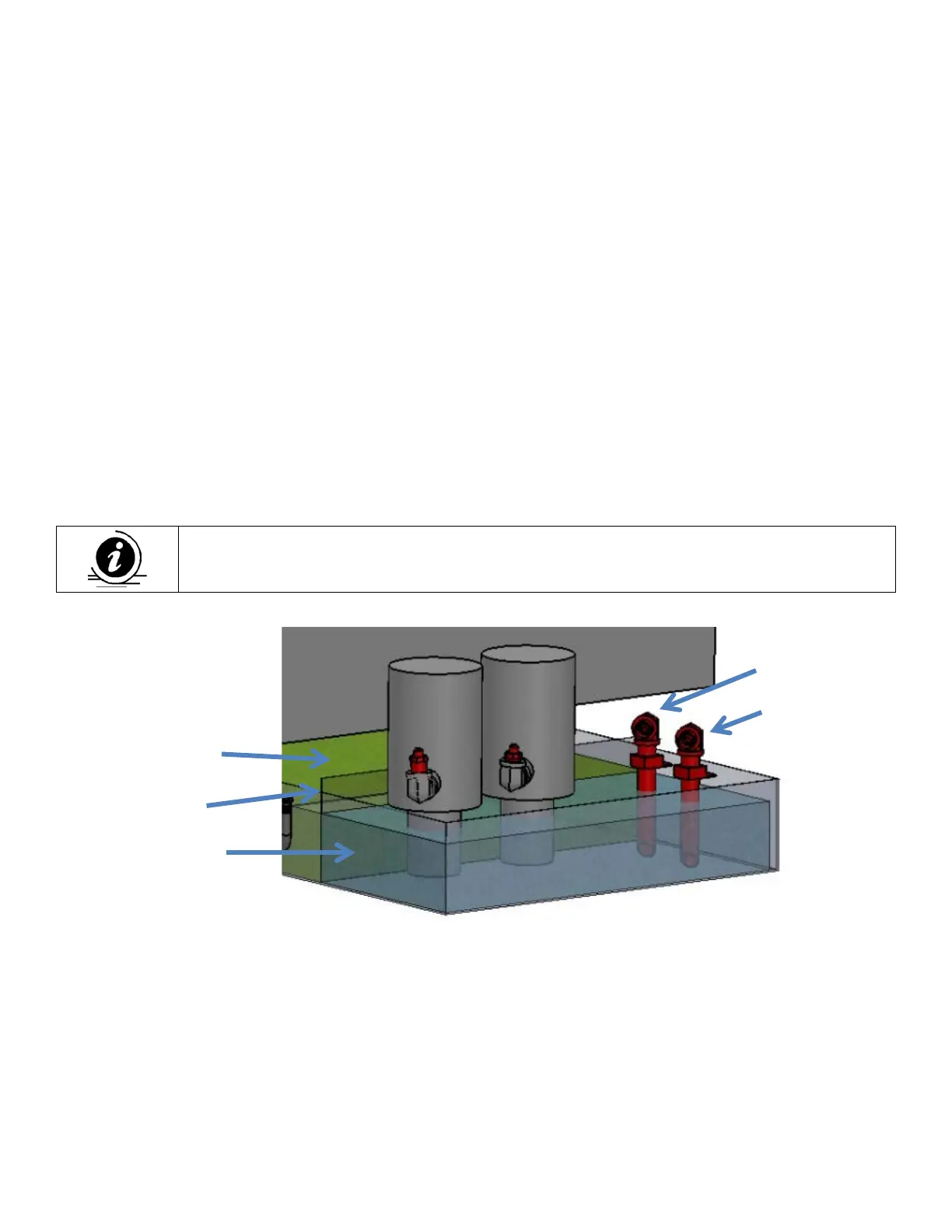

1. Mount supplied weld clamps on clean side of machine tool coolant tank, after the screens,

typically near the low pressure pumps already installed in tank;

Use open area of tank. If no opening available, use 1 1/4" conduit punch or equivalent

size hole saw.

Be sure to place inlet dip tube away from low pressure pumps present in machine tool

tank and that dip tube stays in contact with bottom of the tank. This will ensure proper

suction of coolant.

2. Run inlet & return hoses to their respected connections on unit;

Inlet & return are clearly marked on unit.

Inlet dip tube will always be longer than return dip tube.

• If low level plate will not fit in tank, use supplied 45” pipe fitting

Use supplied hose clamps to install hoses.

Inlet & return hoses should be no longer than 15’.

Hoses must be placed below inlet of unit, to ensure proper priming of the unit.

Do not place hoses on top of unit or stand vertically.

Screen

Dirty Side

Clean Side

Inlet

Return

Loading...

Loading...