Manual# I27028 4-2 Rev. 2 – 11/22/2017

• Air inlets and outlets, process and reactivation. If an air inlet or outlet is operated

without ductwork, allow a clearance of at least 24" in front of the inlet.

• Air filters

• Electrical control panels

• Gas train enclosures

• Damper access

• Wheel removal

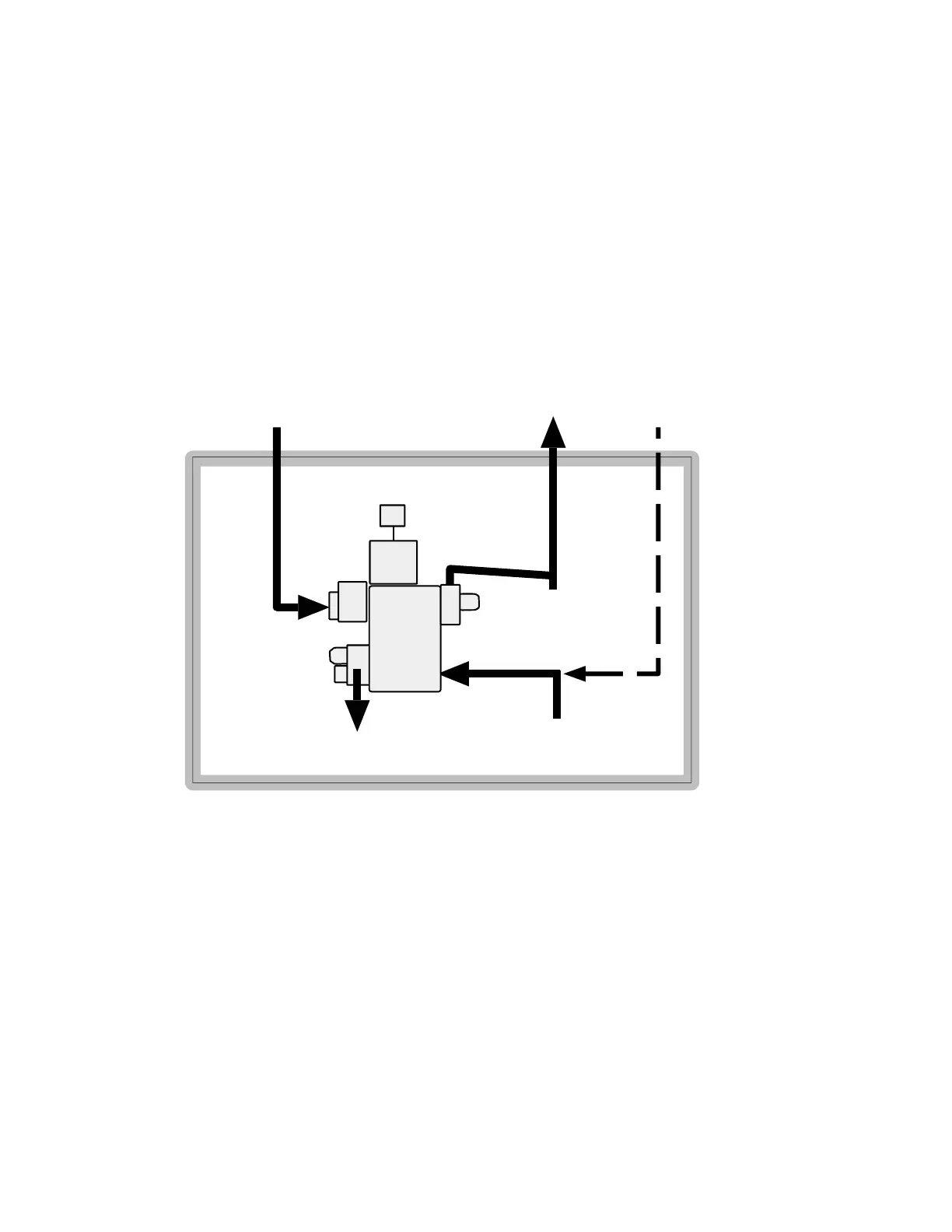

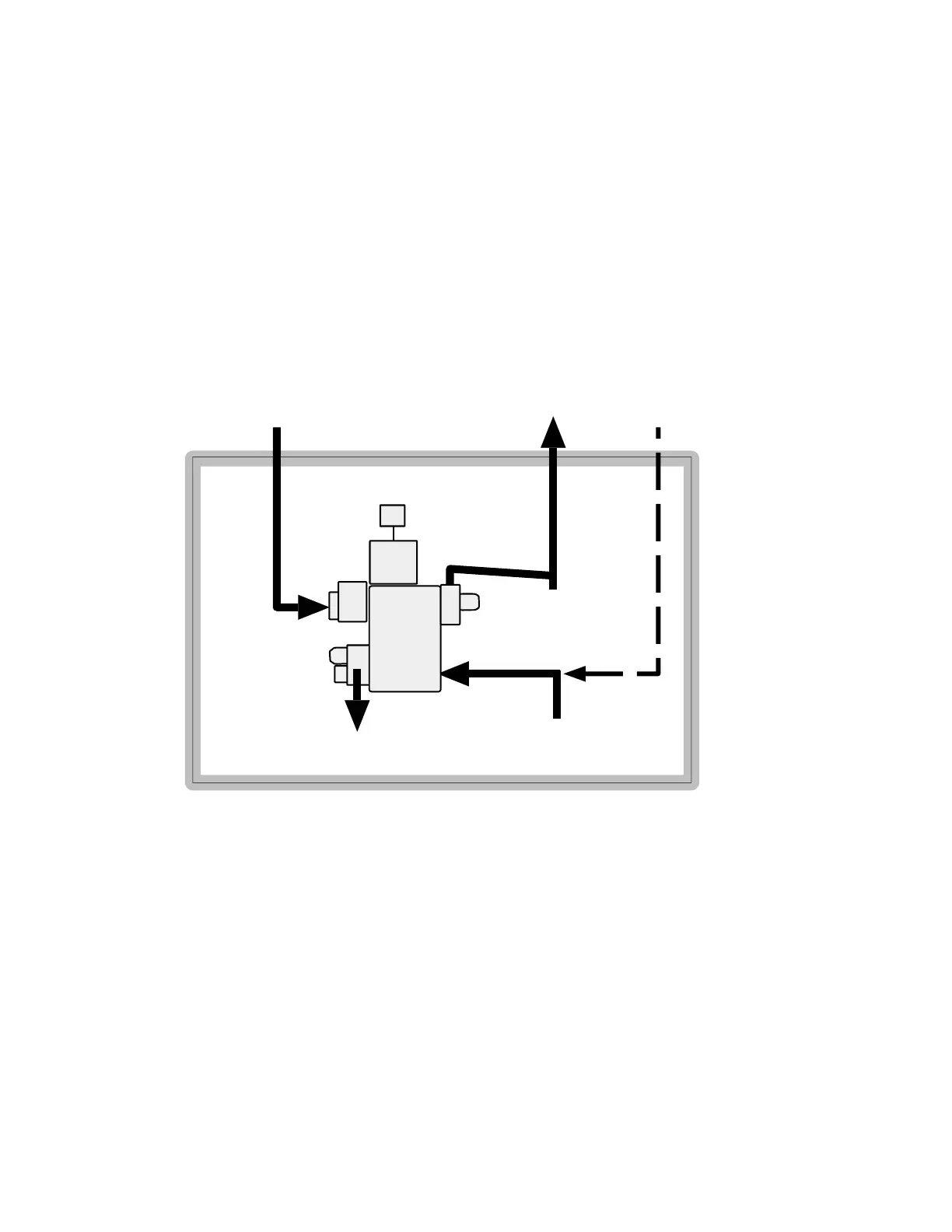

2. Figure 4-1, Figure 4-2, and Figure 4-3 show four different ways of installing the R-

Series unit.

Figure 4-1

INSTALLATION IN PROCESS SPACE

3. To minimize condensation on the outside of the unit when it is not running, the

dehumidifier can be placed inside a cool space, rather than outdoors. This will

reduce the amount of condensation forming on the outside of the unit. See Figure

4-3.

4. The R-Series unit handles two separate streams of air:

• The process air, which comes from the space which is to be dehumidified

• The reactivation air, which comes from outside of the space to be dehumidified.

This air is used to remove the moisture from the HoneyCombe

®

wheel inside

the unit.

The process air intake should come from the conditioned space, and the process air

outlet should be vented to the same space. The process air intake can be quite

close to the machine. In fact, it can be operated without any ductwork on the

process intake. (The other openings will still need ductwork, however.) If the two

process air ducts have different lengths, and one of the ducts must run a long way,

the long duct should handle the process output air.

Process air OUT –

to process space

Process air IN –

from process space

Reactivation air IN –

from outdoors

Reactivation air OUT –

to outdoors

Optional makeup air –

from outdoors

OUTDOORS

PROCESS SPACE

(STORAGE AREA)

HUMIDISTAT

(option)

Loading...

Loading...