Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 2-44 P/N 196515 (Revision A)

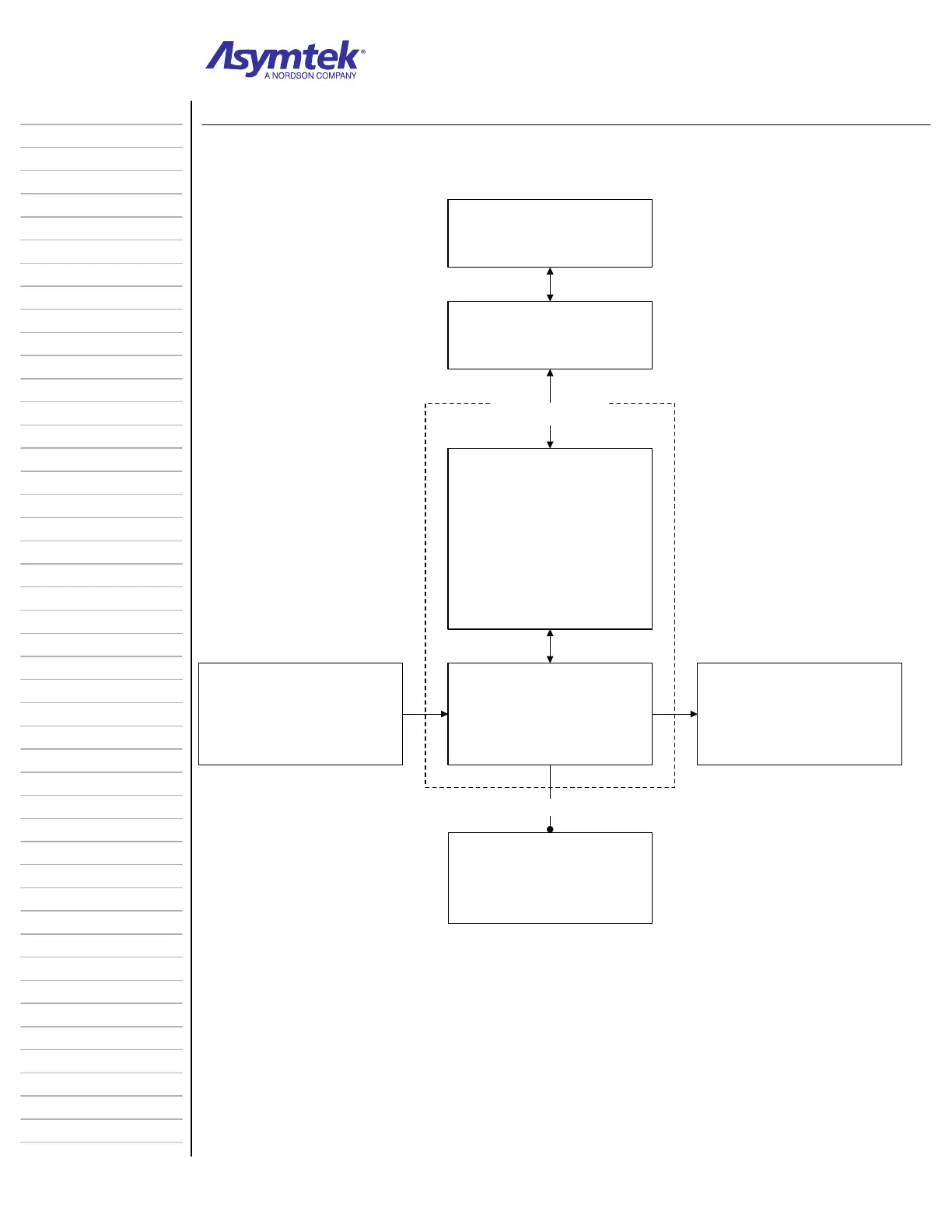

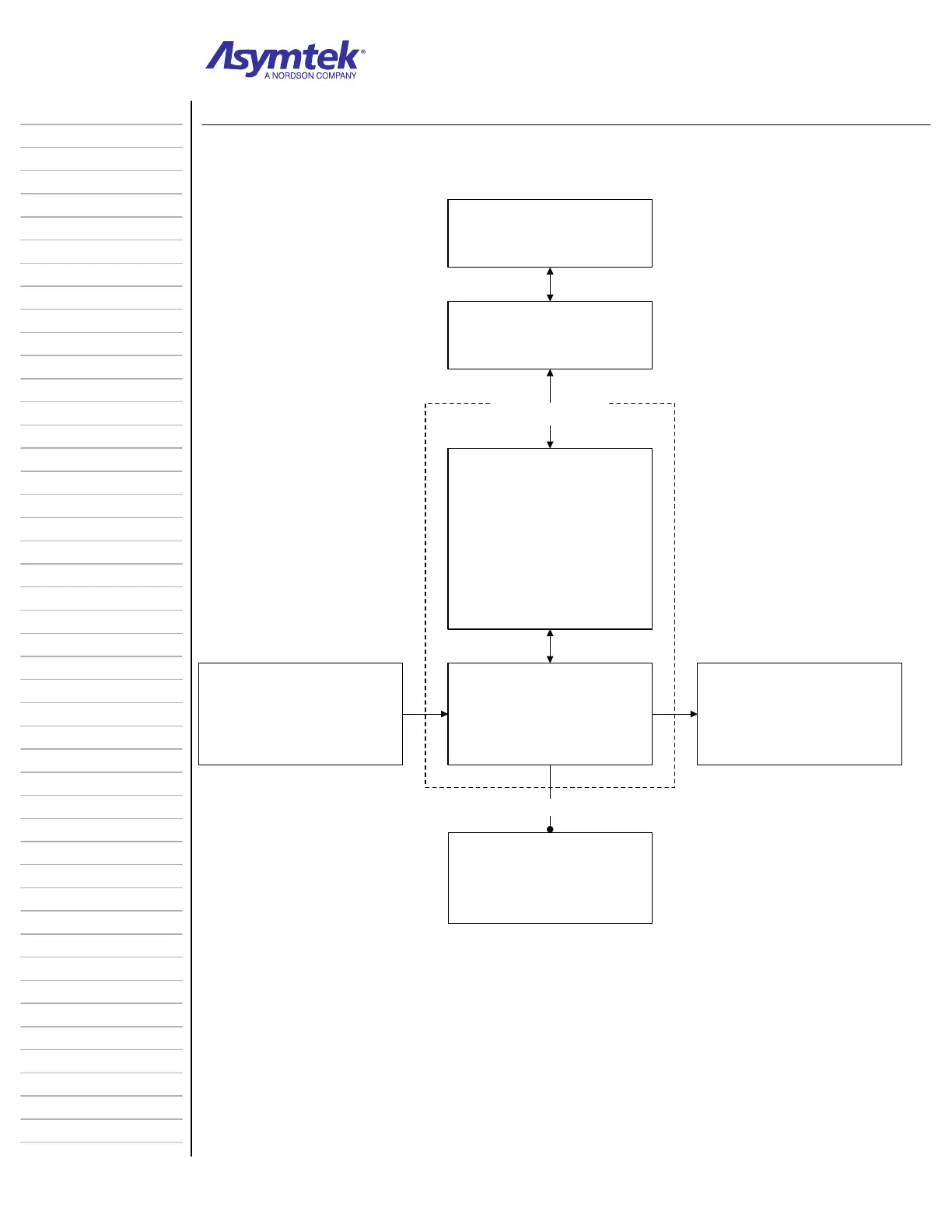

Diagram Sheet 2-5-5

Conveyor Belt Moves

FmNT Command

y

A program command is issued to the

FmNT software.

Controller Area Network (CAN)

y

Communications network between

Computer (FmNT) and Conveyor

Controller Module

Conveyor Interface PWA

y

Performs conveyor logical functions

such as belt movement (direction,

duration and speed), width adjustment,

operation of pneumatic solenoid valves

for clamps/lift tables, stop pins,

operation of heaters, and SMEMA

communication.

y

Receives execution commands and

system setup parameters from FmNT.

Sends conveyor states and status to

FmNT.

Conveyor Stepper Motors

y

Two motors drive the Conveyor belts to

move the workpiece through the

dispensing system.

y

One motor drives the rear Conveyor

Rail to adjust width between rails.

Conveyor Interconnect PWA

y

Passively routes signals between

conveyor controller and individual

conveyor components (sensors,

solenoids, motors).

Pneumatic Solenoids

y

Signals from Conveyor Controller open

or close pneumatic solenoid valves,

which operate stop pins, lift tables or

clamp bars, and activate the vacuum

generators for the Purge Station.

Board Sensors

y

Detects presence of work pieces in pre-

dispense, dispense, and post-dispense

locations. Signals are routed to

Conveyor Controller via Conveyor

Interconnect PWA.

Motor Cables

Conveyor/Heater

Controller

Loading...

Loading...