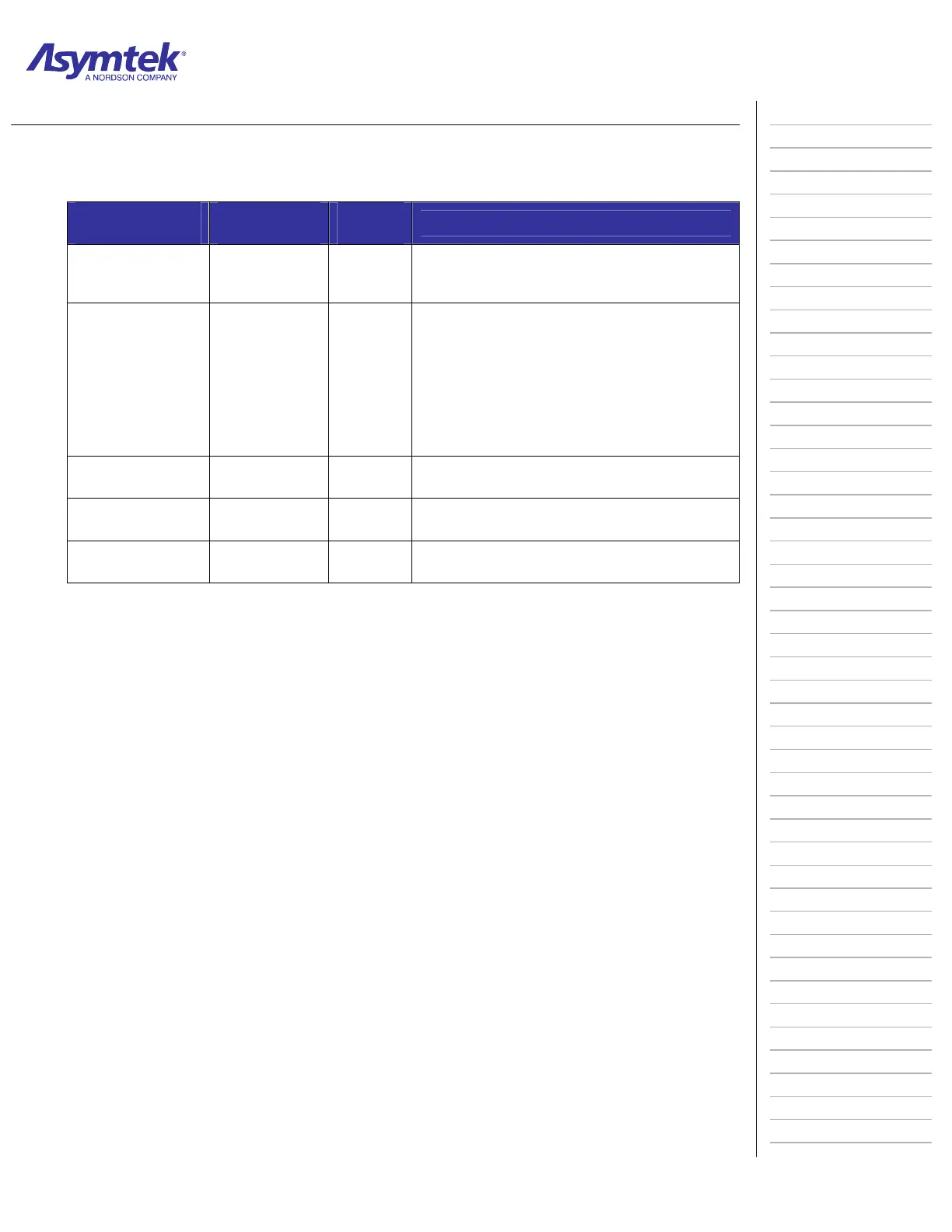

Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 3-3 P/N 196515 (Revision A)

Information Sheet 3-1-2

Routine Maintenance Procedure Schedule (Continued)

Maintenance

Procedure

Recommended

Frequency

Est.

Time

Instructions

Lubricate the X-

and Y-Axis

bearings.

Monthly

30

minutes

See Exercise Sheet 3-5-1 on page 3-24.

Clean Board

Sensors.

Monthly

30

minutes

Use a clean, soft cloth to wipe any dust off of the

sensors.

• Clean, dry pressurized air may be used if

your application does not use thermal

grease.

• Depending on your system configuration,

there may be as many as three Board

Sensors present.

Lubricate the

Mechanical Cables.

Quarterly

30

minutes

See Exercise Sheet 3-6-1 on page 3-28.

Replace Conveyor

Belts.

Semi-annually

30

minutes

See Exercise Sheet 3-7-1 on page 3-35 and

Exercise Sheet 3-7-2 on page 3-36.

Calibrate the Scale. Semi-annually

20

minutes

See Exercise Sheet 3-3-3 on page 3-16.

Loading...

Loading...