Training Guide Course No. 196514

Level 2 Maintenance, X-1000 Series Dispensing Systems 4-76 P/N 196515 (Revision A)

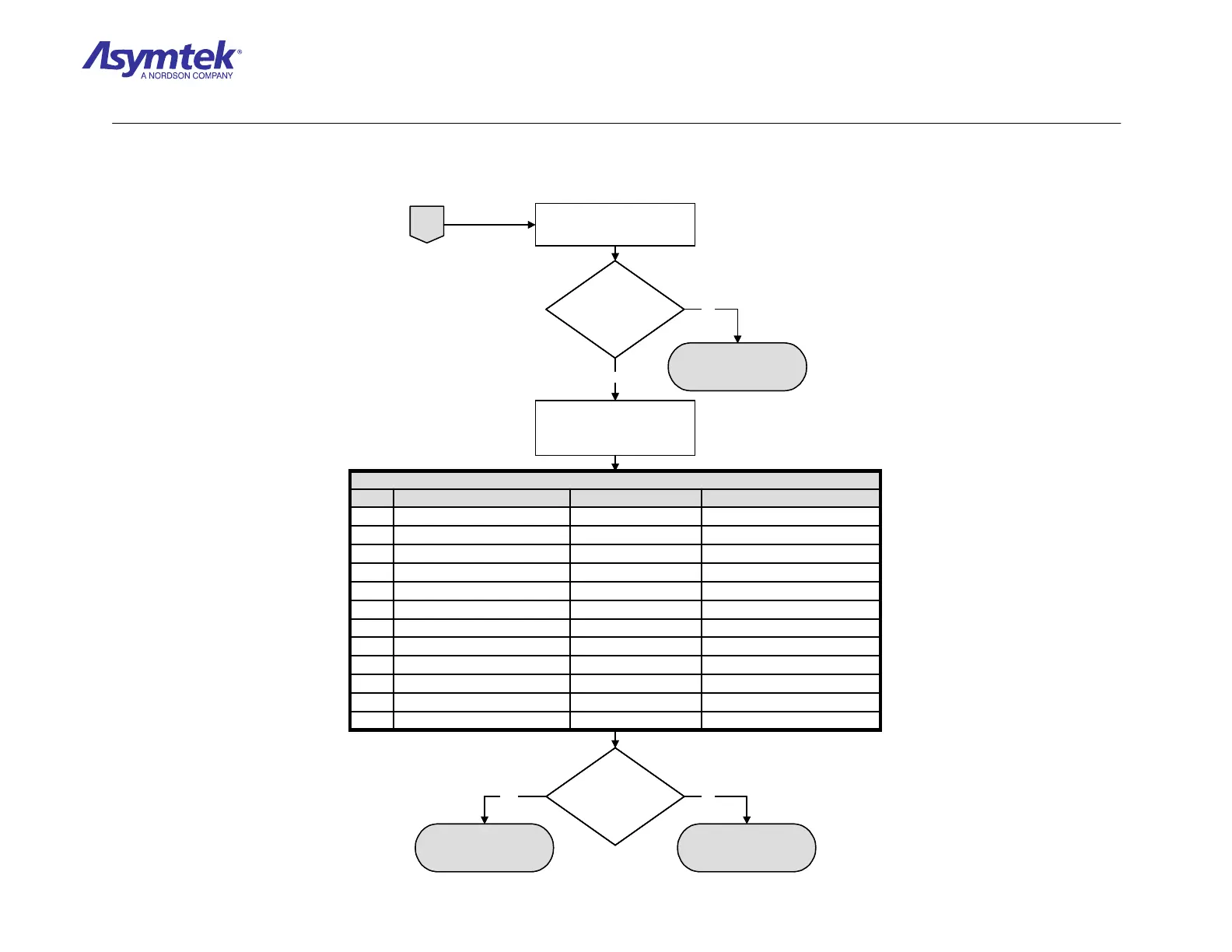

Check continuity of Rotary

Encoder Cable

(P/N 06-4535-00).

Does the Cable have

continuity?

The isolated part has

failed

Y-axis Rotary Encoder

(P/N 62-1650-01) has

failed

A

Check continuity of signal

routing from the Y-axis

Rotary Encoder as specified

in Table 2.

Pin 14 at J8 PMAC ControllerCable P/N 06-4523-00Pin 14 at J9 (Main Interface)A

Pin 13 at J8 PMAC ControllerCable P/N 06-4523-00Pin 13 at J9 (Main Interface)B

Pin 14 at J9 (Main Interface)Main Interface PWAPin 22 at J29 (Main Interface)A

Pin 13 at J9 (Main Interface)Main Interface PWAPin 23 at J29 (Main Interface)B

Pin 22 at J29 (Main Interface)Cable P/N 06-4525-00Pin 22 at J19 (XY Servo Interface)A

Pin 23 at J29 (Main Interface)Cable P/N 06-4525-00Pin 23 at J19 (XY Servo Interface)B

Pin 22 at J19 (XY Servo Interface)XY Servo Interface PWAPin 13 at J9 (XY Servo Interface)A

Pin 23 at J19 (XY Servo Interface)XY Servo Interface PWAPin 14 at J9 (XY Servo Interface)B

Pin 13 at J9 (XY Servo Interface)Cable P/N 06-0403-00Pin 13 at J5 (Servo Amp)A

Pin 14 at J9 (XY Servo Interface)Cable P/N 06-0403-00Pin 14 at J5 (Servo Amp)B

Pin 13 at J5 (Servo Amp)Y-axis Servo Amp PWAPin 5 at J3 (Servo Amp)A

Pin 14 at J5 (Servo Amp)Y-axis Servo Amp PWAPin 3 at J3 (Servo Amp)B

To (PWA)ViaFrom (PWA)Signal

TABLE 2 – Y-Axis Rotary Signal Routing

Is there continuity

of signal routing for

Y-axis Rotary

Encoder?

Yes No

Rotary Encoder Cable

(P/N 06-4535-00) has

failed.

No

Yes

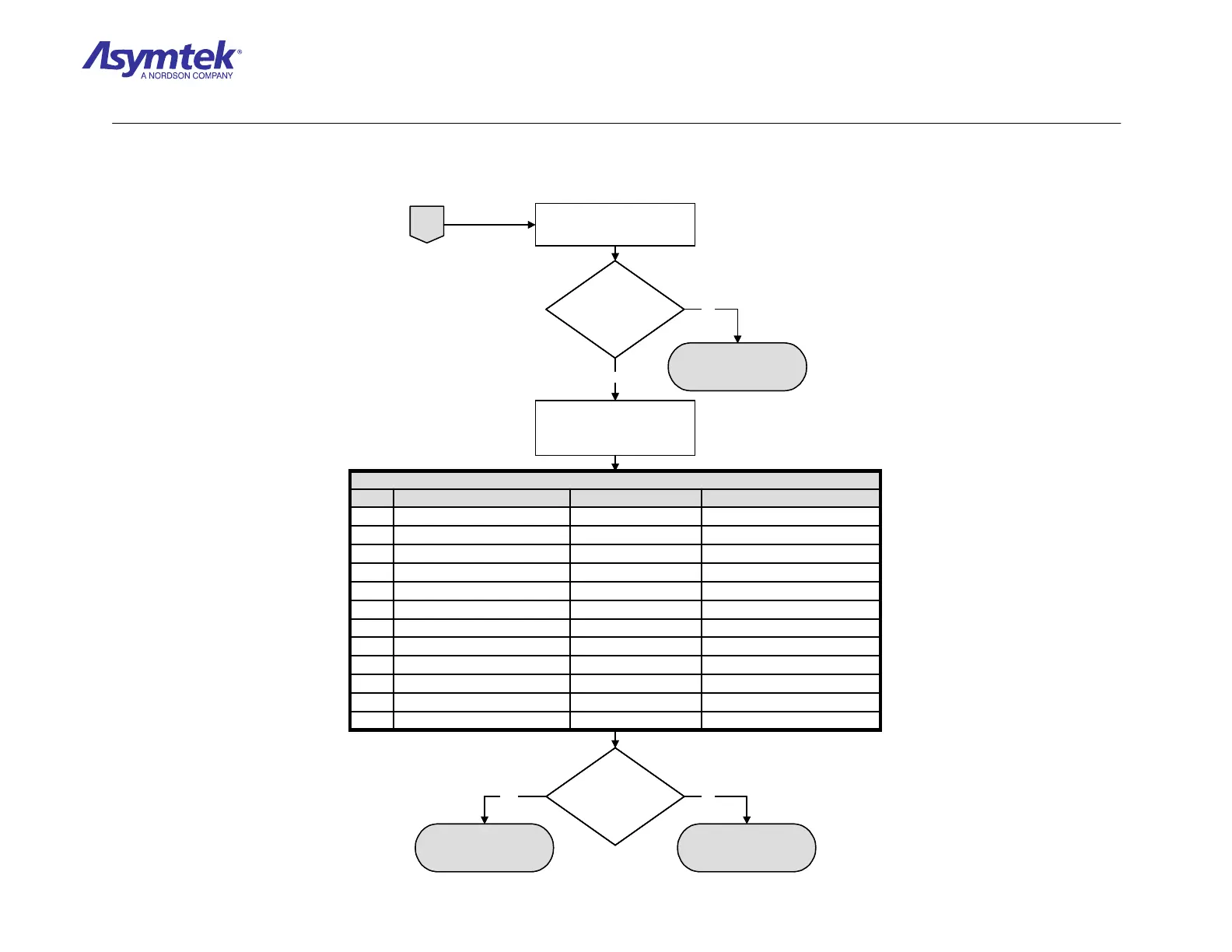

Check continuity of Rotary

Encoder Cable

(P/N 06-4535-00).

Does the Cable have

continuity?

Does the Cable have

continuity?

The isolated part has

failed

Y-axis Rotary Encoder

(P/N 62-1650-01) has

failed

A

Check continuity of signal

routing from the Y-axis

Rotary Encoder as specified

in Table 2.

Pin 14 at J8 PMAC ControllerCable P/N 06-4523-00Pin 14 at J9 (Main Interface)A

Pin 13 at J8 PMAC ControllerCable P/N 06-4523-00Pin 13 at J9 (Main Interface)B

Pin 14 at J9 (Main Interface)Main Interface PWAPin 22 at J29 (Main Interface)A

Pin 13 at J9 (Main Interface)Main Interface PWAPin 23 at J29 (Main Interface)B

Pin 22 at J29 (Main Interface)Cable P/N 06-4525-00Pin 22 at J19 (XY Servo Interface)A

Pin 23 at J29 (Main Interface)Cable P/N 06-4525-00Pin 23 at J19 (XY Servo Interface)B

Pin 22 at J19 (XY Servo Interface)XY Servo Interface PWAPin 13 at J9 (XY Servo Interface)A

Pin 23 at J19 (XY Servo Interface)XY Servo Interface PWAPin 14 at J9 (XY Servo Interface)B

Pin 13 at J9 (XY Servo Interface)Cable P/N 06-0403-00Pin 13 at J5 (Servo Amp)A

Pin 14 at J9 (XY Servo Interface)Cable P/N 06-0403-00Pin 14 at J5 (Servo Amp)B

Pin 13 at J5 (Servo Amp)Y-axis Servo Amp PWAPin 5 at J3 (Servo Amp)A

Pin 14 at J5 (Servo Amp)Y-axis Servo Amp PWAPin 3 at J3 (Servo Amp)B

To (PWA)ViaFrom (PWA)Signal

TABLE 2 – Y-Axis Rotary Signal Routing

Pin 14 at J8 PMAC ControllerCable P/N 06-4523-00Pin 14 at J9 (Main Interface)A

Pin 13 at J8 PMAC ControllerCable P/N 06-4523-00Pin 13 at J9 (Main Interface)B

Pin 14 at J9 (Main Interface)Main Interface PWAPin 22 at J29 (Main Interface)A

Pin 13 at J9 (Main Interface)Main Interface PWAPin 23 at J29 (Main Interface)B

Pin 22 at J29 (Main Interface)Cable P/N 06-4525-00Pin 22 at J19 (XY Servo Interface)A

Pin 23 at J29 (Main Interface)Cable P/N 06-4525-00Pin 23 at J19 (XY Servo Interface)B

Pin 22 at J19 (XY Servo Interface)XY Servo Interface PWAPin 13 at J9 (XY Servo Interface)A

Pin 23 at J19 (XY Servo Interface)XY Servo Interface PWAPin 14 at J9 (XY Servo Interface)B

Pin 13 at J9 (XY Servo Interface)Cable P/N 06-0403-00Pin 13 at J5 (Servo Amp)A

Pin 14 at J9 (XY Servo Interface)Cable P/N 06-0403-00Pin 14 at J5 (Servo Amp)B

Pin 13 at J5 (Servo Amp)Y-axis Servo Amp PWAPin 5 at J3 (Servo Amp)A

Pin 14 at J5 (Servo Amp)Y-axis Servo Amp PWAPin 3 at J3 (Servo Amp)B

To (PWA)ViaFrom (PWA)Signal

TABLE 2 – Y-Axis Rotary Signal Routing

Is there continuity

of signal routing for

Y-axis Rotary

Encoder?

Is there continuity

of signal routing for

Y-axis Rotary

Encoder?

Yes No

Rotary Encoder Cable

(P/N 06-4535-00) has

failed.

No

Yes

Diagram Sheet 4-6-7

PMAC Rotary Encoders Fault Isolation Procedure – Y-Axis Rotary Encoder Verification (Continued)

Loading...

Loading...