5.8 Crank Sensor

The crank sensor input can be from either a Magnetic Variable Reluctance (MVR) sensor or a Hall

Effect sensor. The two types of sensor require different software and hardware jumper settings.

MVR

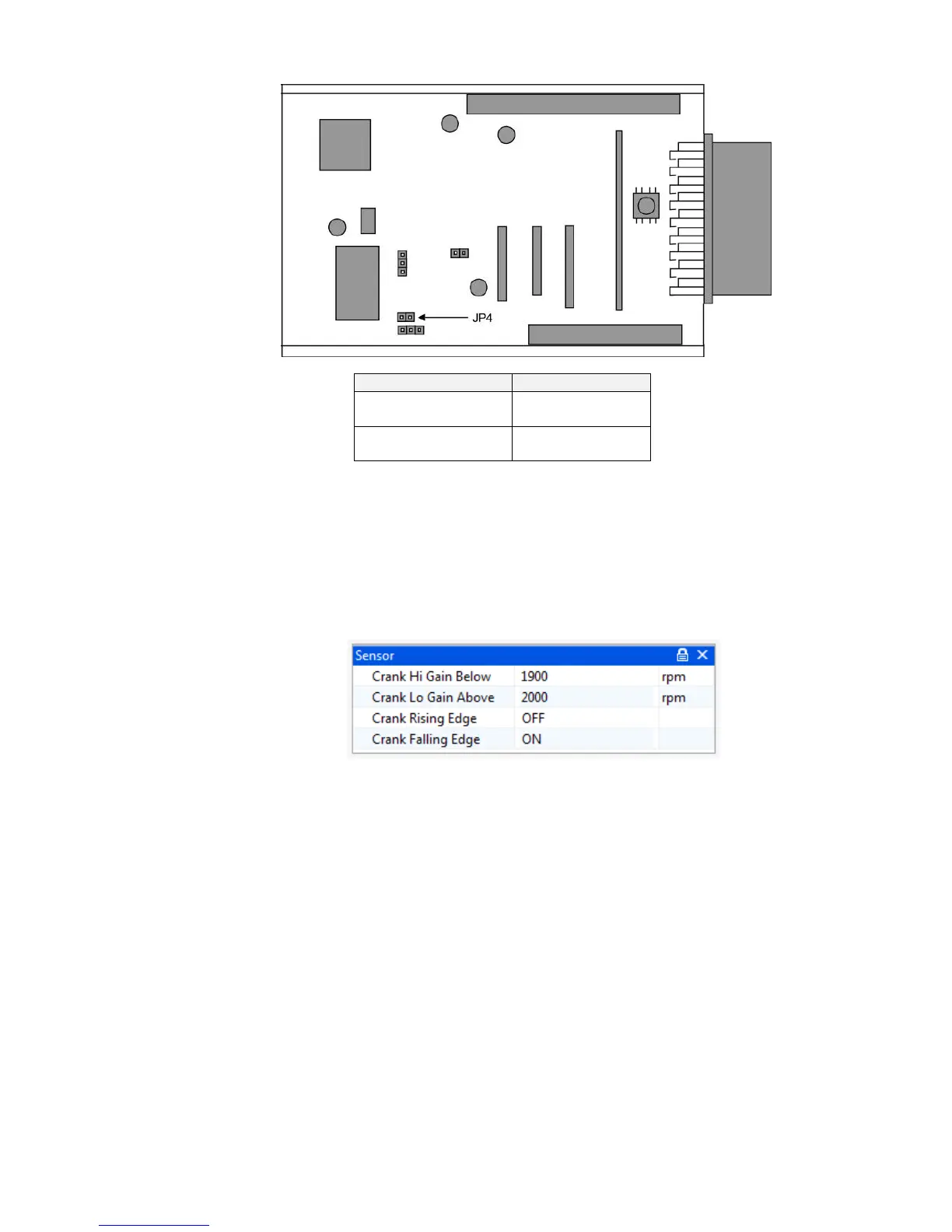

The crank sensor high and low gain settings allow a user definable change point for high sensitivity

to allow for low magnetic crank sensor outputs at low engine speeds. Typically the values are just

above idle speed.

Magnetic sensors can use either the rising or falling edge of the generated waveform. If the edge is

incorrect then the engine will misfire at some point in the engine speed range. There is also the

possibility that if the edge is incorrect on a magnetic sensor of the ignition timing on the engine

deviating from the ignition timing calculated by the ECU as the engine speed changes. To find the

correct edge either see which edge does / does not produce ignition timing changes, or using an

oscilloscope to look at the waveform. If the signal falls through the missing tooth section use Crank

Rising Edge, and if it rises through the missing tooth section use Crank Falling Edge.

Loading...

Loading...