OMEM710 Hardware Manual 2v11

20

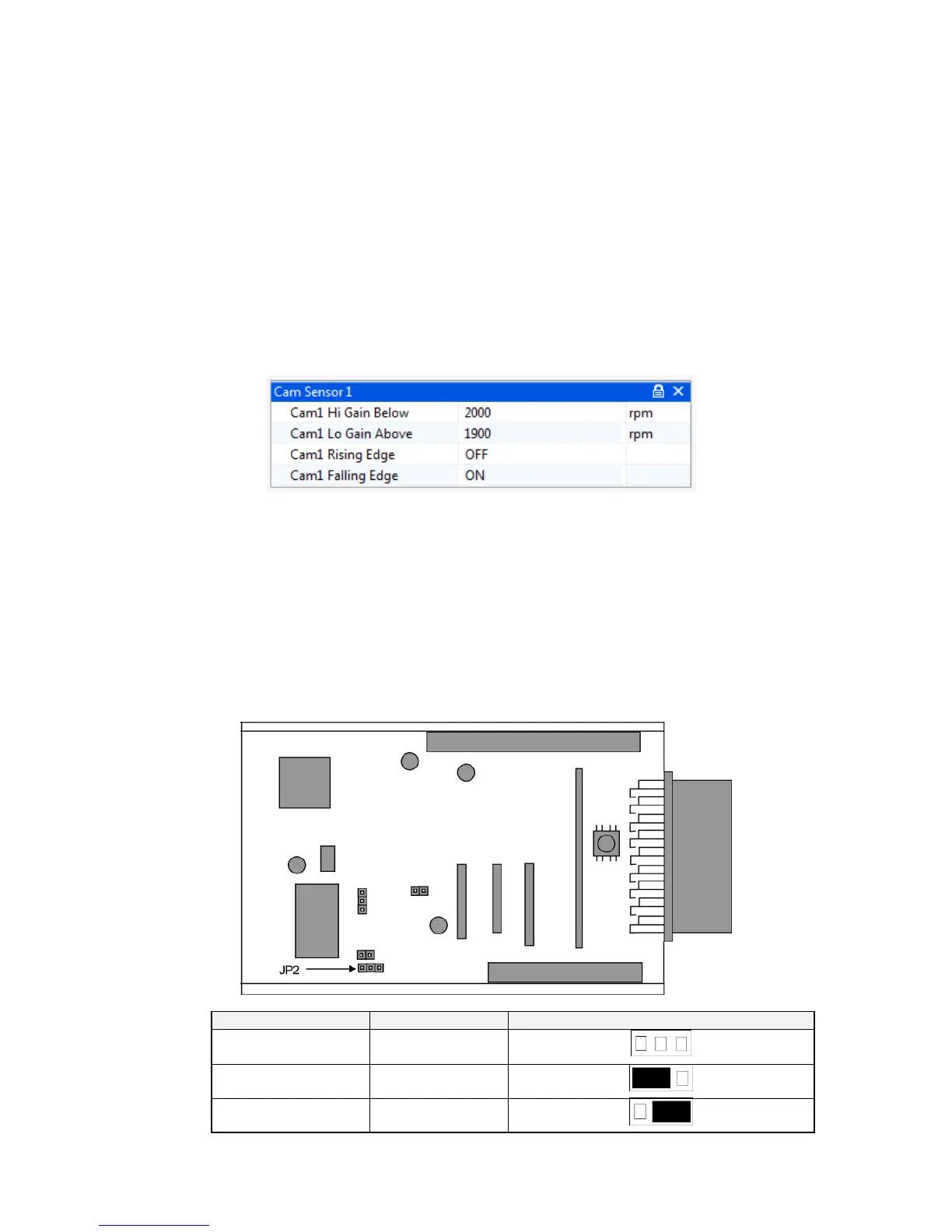

Tooth Control table:

5.10 Cam1 Sensor

If an engine is to control the injectors sequentially or ignition coil-per-plug, it needs information about

what part of the engine cycle it is in (there are two crank revolutions per engine cycle for a 4 stroke

engine). The cam sensor provides this information (as there is only one cam revolution per engine

cycle for a 4 stroke engine).

Some VR cam sensors give too high an output at high engine speeds.

This feature allows the sensitivity of the ECU to be switched to lower

above the set engine speed to allow for this. Typically 1500rpm.

High channel sensitivity when below this value. Should be set below the

on value (hysteresis). Logic level sensors (hall effect) set to 0

rising edge of the crank signal is used as the significant edge if ON.

Typically OFF

falling edge of the crank signal is used as the significant edge if ON.

Typically ON

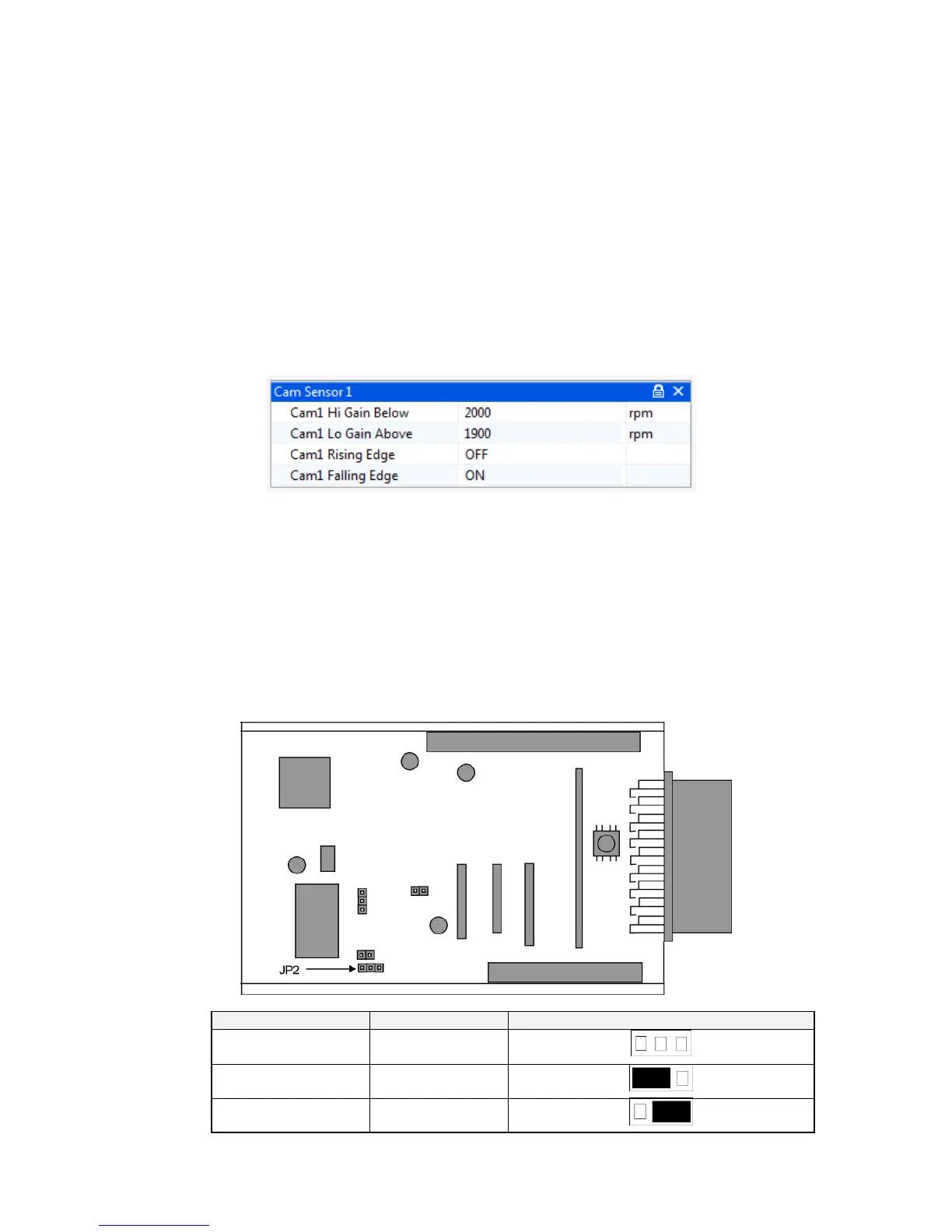

The cam input can be from either a MVR or Hall sensor. Jumpers on the board must be set to allow

for these two sensor types.

Loading...

Loading...