OMEM710 Hardware Manual 2v11

50

Engines make mechanical noise that varies dependent on engine speed. The Knock Ambient

Noise Table describes this normal background engine noise when running out of knock. The

parameter KNKRAW shows the current noise measured by the knock sensor. Logging the

parameter KNKRAW on a full load engine run whilst using a safe ignition map allows you to draw

the table of normal noise.

When KNKRAW exceeds the Knock Ambient Noise table values, the engine is assumed to be in

knock. The level of noise above the normal noise is shown by the parameter Knock.

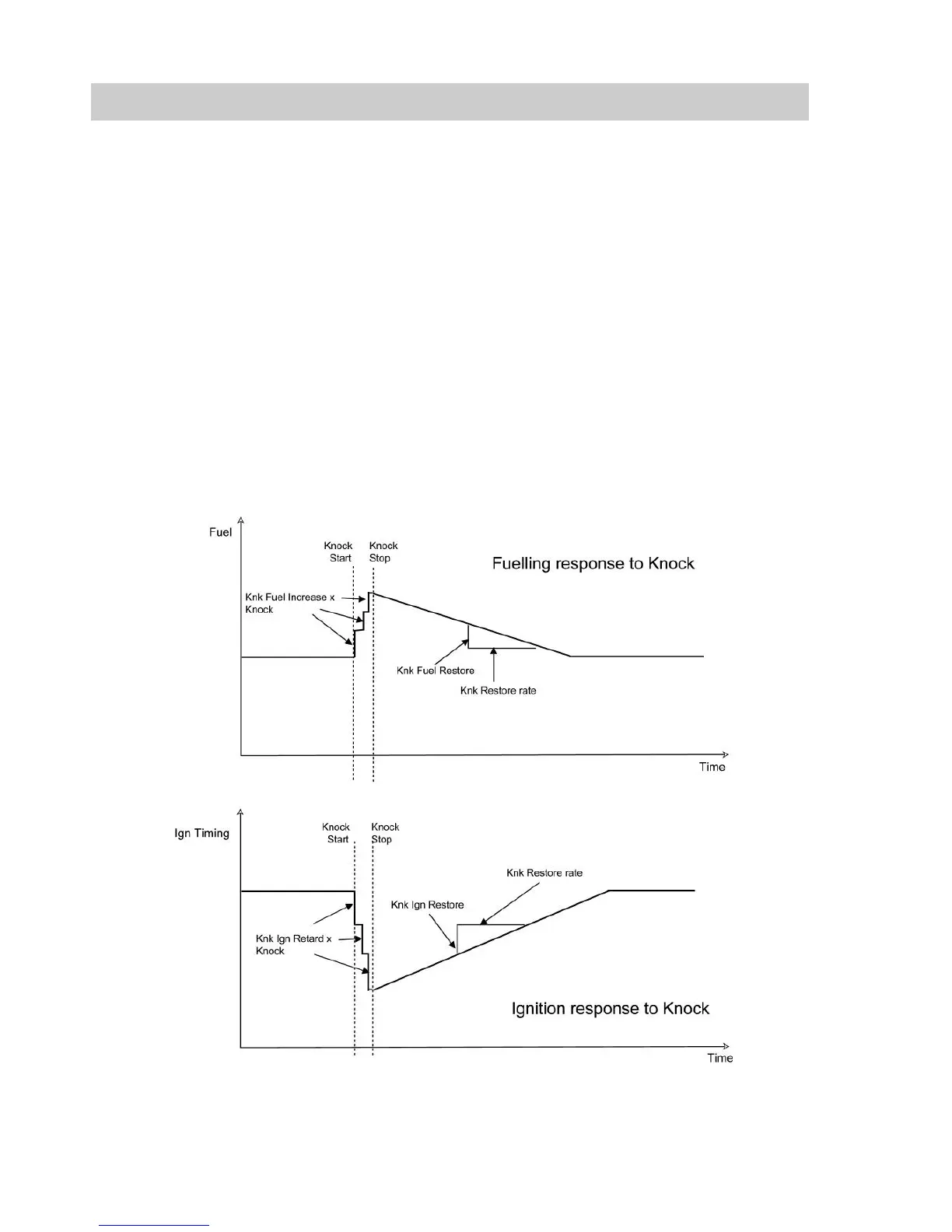

When knock is discovered, the ECU needs to react by retarding the ignition to stop knock, and

increase the fuelling to cool the cylinder.

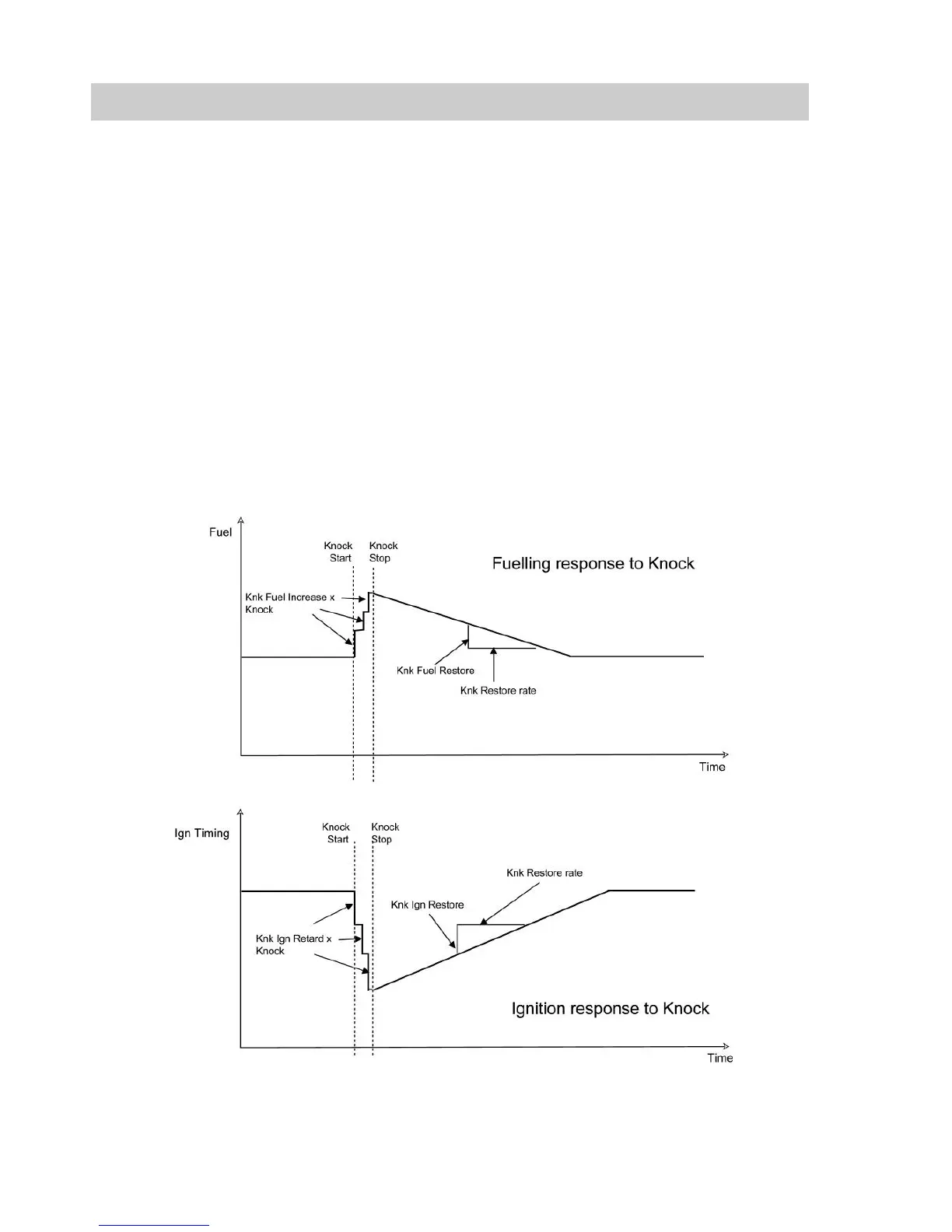

The Knock value causes an ignition retard (Knk Ign Retard) and an increase in fuel (Knk Fuel

Increase) proportional to the Knock level. The ECU will make these changes to the timing and

fuelling every 4ms until knock has stopped. The extra fuel and the ignition retard are capped to a

maximum regardless of the calculated values by Knk Fuel max and Knk Ign Retard max.

After knock has stopped, the fuelling and ignition values need to be returned to normal. The rate is

set by Knk Restore Rate (engine revolutions) and then Knk Fuel Restore (% fuel per rate) and

Knk Ign Restore (degrees ignition timing per rate).

Loading...

Loading...