OMEM710 Hardware Manual 2v11

26

The amount of fuel injected each cycle is dependent on the time the injector is open. This time

period (or pulse width) is calculated by the ECU using the values found in the main fuel map and all

of the modifiers such as transient fuel, cold start enrichment etc.

On the main fuel map, at each intersection of an engine speed site and an engine load site there is a

grid value. This is the VE value and is directly proportional to the pulse width and therefore the

amount of fuel injected.

These values are determined by running the engine on a dynamometer at each obtainable point and

adjusting the VE values to obtain optimum performance. (ie mapping the engine).

If the engine is running at an exact engine speed site and an exact engine load site then the VE

value at the intersection of these two sites will determine the amount of fuel injected. If running at a

condition where it is not exactly on a mapped site, the ECU interpolates between the nearest sites.

The fuel pulsewidth from the main fuel map is calculated as follows;

Base fuel pulsewidth = raw (map) value x Microsec/bit

As a starting point it is quite acceptable to set Microsec/bit to 50. This will give a very good starting

point for most engine setups. Once a sample full throttle point around maximum torque has been

trial mapped, the Microsec/bit can be adjusted to give a maximum fuel map setting of 200 or so. If

working from a reasonable start-up calibration, set the engine to be very slightly rich overall by

adjusting Microsec/bit, then map sites from this point. Once a rough calibration is made, the fuel

map can be rescaled (see below) to give better resolution.

Fuel Sync is the overall injection start point delay measured in internal units, A change in value of 1

is a change in start point of 30 crank degrees. This number can be changed to give the best

emissions or power.

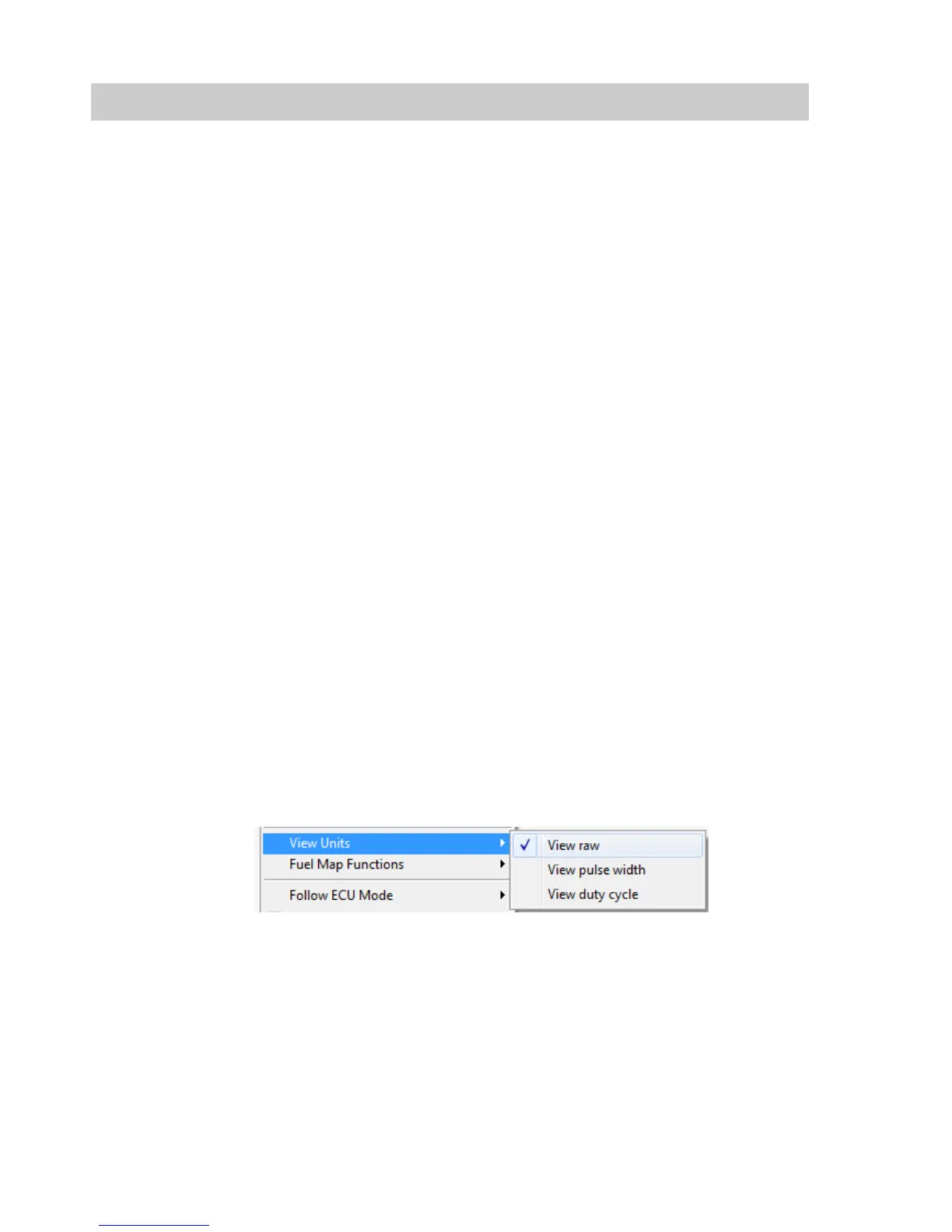

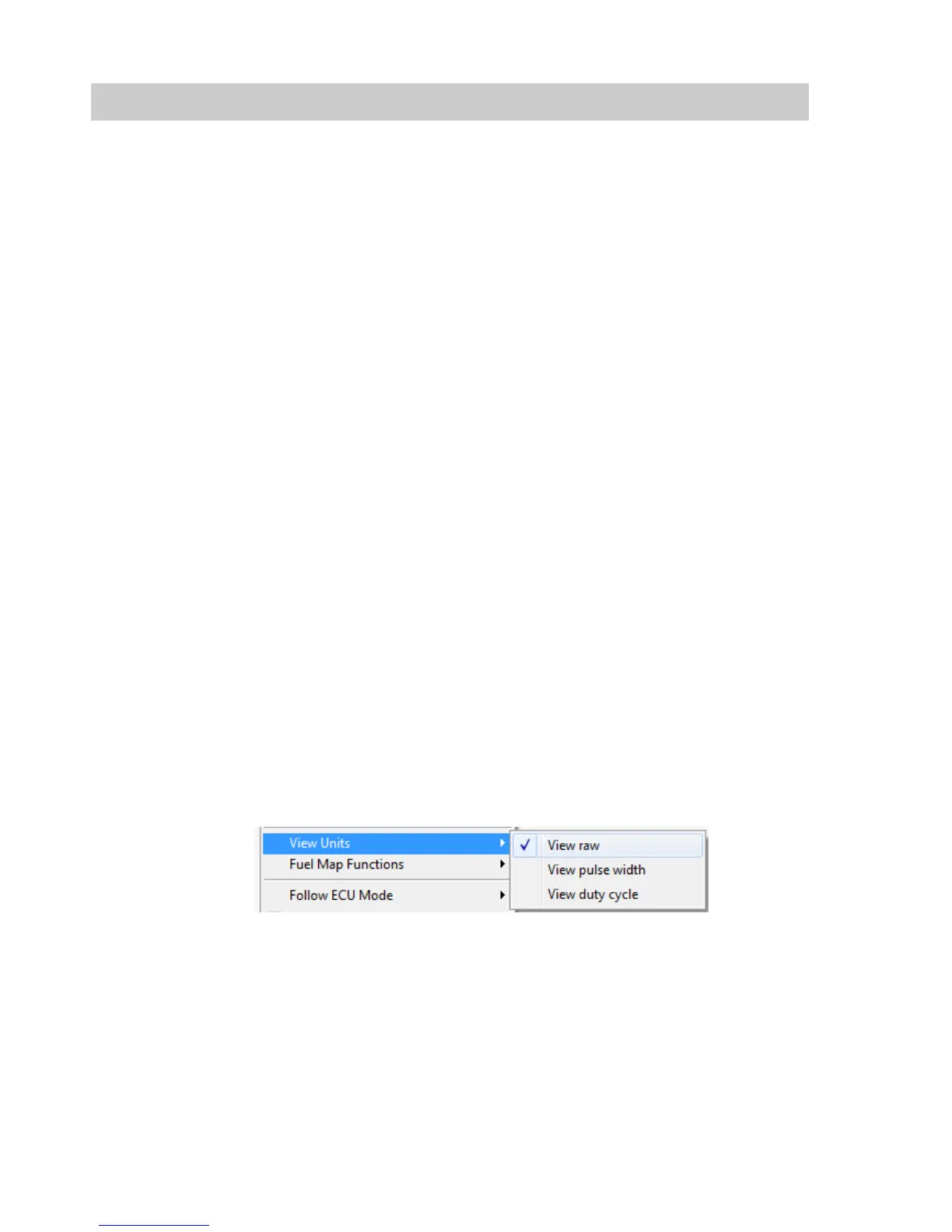

Fuel maps have six additional commands in the pop-up menu. Three View commands change the

units the map is displayed in. The other three commands alter the fuel map to achieve better

scaling.

View commands

Available by a right-click on the fuel map, a pop-up menu gives three view commands to select the

units the fuel map is displayed in. Only one view command can be checked at any one time.

View raw - Shows the raw value of the map as stored in the ECU. These are the values that

should used during engine mapping. It has a range of 0 to 255. When selected, the caption of

the map window shows Raw.

View pulse width - Shows the actual injector pulse width in milliseconds before any

modifications. When selected, the caption of the map window shows Pulse Width. This view

mode should be used for reference only, not for inputting data whilst mapping.

View duty cycle - Shows the percentage of time that the injectors are actually open. When

selected, the caption of the map window shows Duty Cycle. In order for MAP4000 to correctly

calculate the duty cycle, when View duty cycle is selected, it prompts for the number of

injections per engine revolution. This view mode should be used for reference only, not for

inputting data whilst mapping.

Loading...

Loading...