EN-29

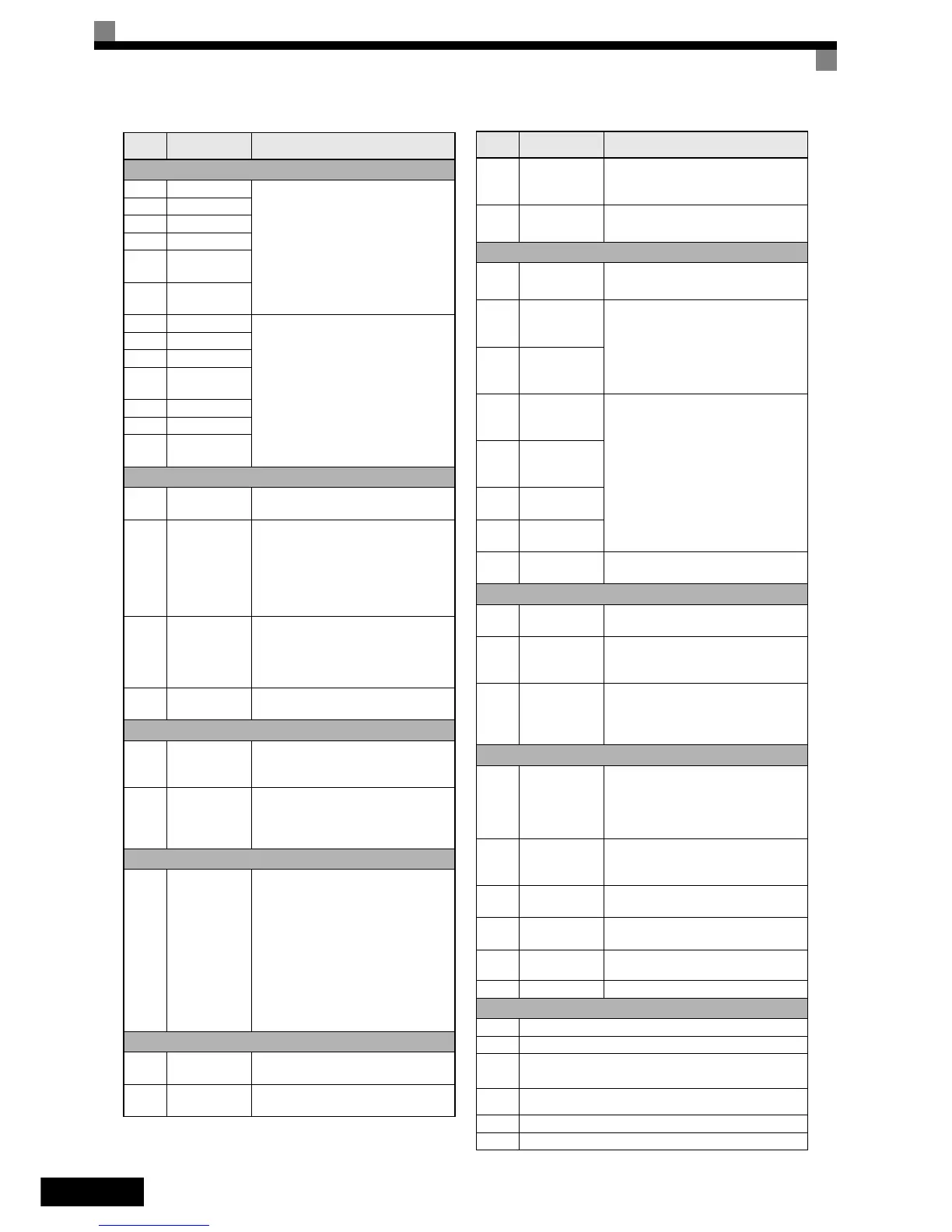

Motor Data Settings

E2-01 Rated current

Motor Data for induction motors

E2-02 Rated slip

E2-03 No-load current

E2-04 Pole number

E2-05

Line-to-line

resistance

E2-06

Leak induct-

ance

E5-02 Rated power

Motor Data for PM motors

E5-03 Rated current

E5-04 Pole number

E5-05

Line-to-line

resistance

E5-06 d-Inductance

E5-07 q- Inductance

E5-09

Motor voltage

constant

Encoder Feedback Settings

F1-01 PG constant

Sets the number of PG pulses per revolu-

tion

F1-05

PG rotation

direction

0:Phase A leads with forward run com-

mand. (Phase B leads with reverse

run command; Counter Clockwise

rotation)

1:Phase B leads with forward run com-

mand. (Phase A leads with reverse run

command; Clockwise rotation)

F1-21

Absolute

encoder resolu-

tion (Hiperface

or EnDat)

0:16384

1:32768

2:8192

(if EnDat is selected (n8-35=5), F1-21 is

fixed to 2)

F1-22

Magnet posi-

tion offset

Sets the Offset between the rotor magnet

and encoder zero position.

Digital I/O Settings

H1-01

to

H1-05

Terminal S3 to

S7 function

selection

Refer to the end of this list for a list of

selections

H2-01

to

H2-03

Terminal M1-

M2/M3-M4/

M5-M6 func-

tion selection

Refer to the end of this list for a list of

selections

Motor Protection

L1-01

Motor protec-

tion selection

0:Disabled

1:General-purpose motor protection

(fan cooled motor)

2:Inverter motor protection (externally

cooled motor)

3:Vector motor protection

When the Inverter power supply is

turned off, the thermal value is reset, so

even if this parameter is set to 1, pro-

tection may not be effective.

5:Permanent magnet constant torque

motor protection

Feed Forward Compensation

n5-01

Feed forward

control sel.

0:Disabled

1:Enabled

n5-02

Motor accelera-

tion time

Param.

Num.

Name Description

n5-03

Feed forward

proportional

gain

Speed reference response will increase as

the setting of n5-03 is increased.

n5-05

Motor accelera-

tion time tuning

0:Disabled

1:Enabled

Brake Sequence

S1-01

Zero Speed

level at stop

Sets the brake close command speed level

at stop.

S1-02

DC injection

braking current

at start

Sets as a percentage of the Inverter rated

current.

S1-03

DC injection

braking current

at stop

S1-04

DC inj. braking/

Zero speed time

at start

Refer to page 22, Brake Sequence.

S1-05

DC inj. braking/

Zero speed time

at stop

S1-06

Brake release

delay time

S1-07

Brake close

delay time

S1-20 Zero-servo gain

Zero servo position loop gain for closed

loop vector control.

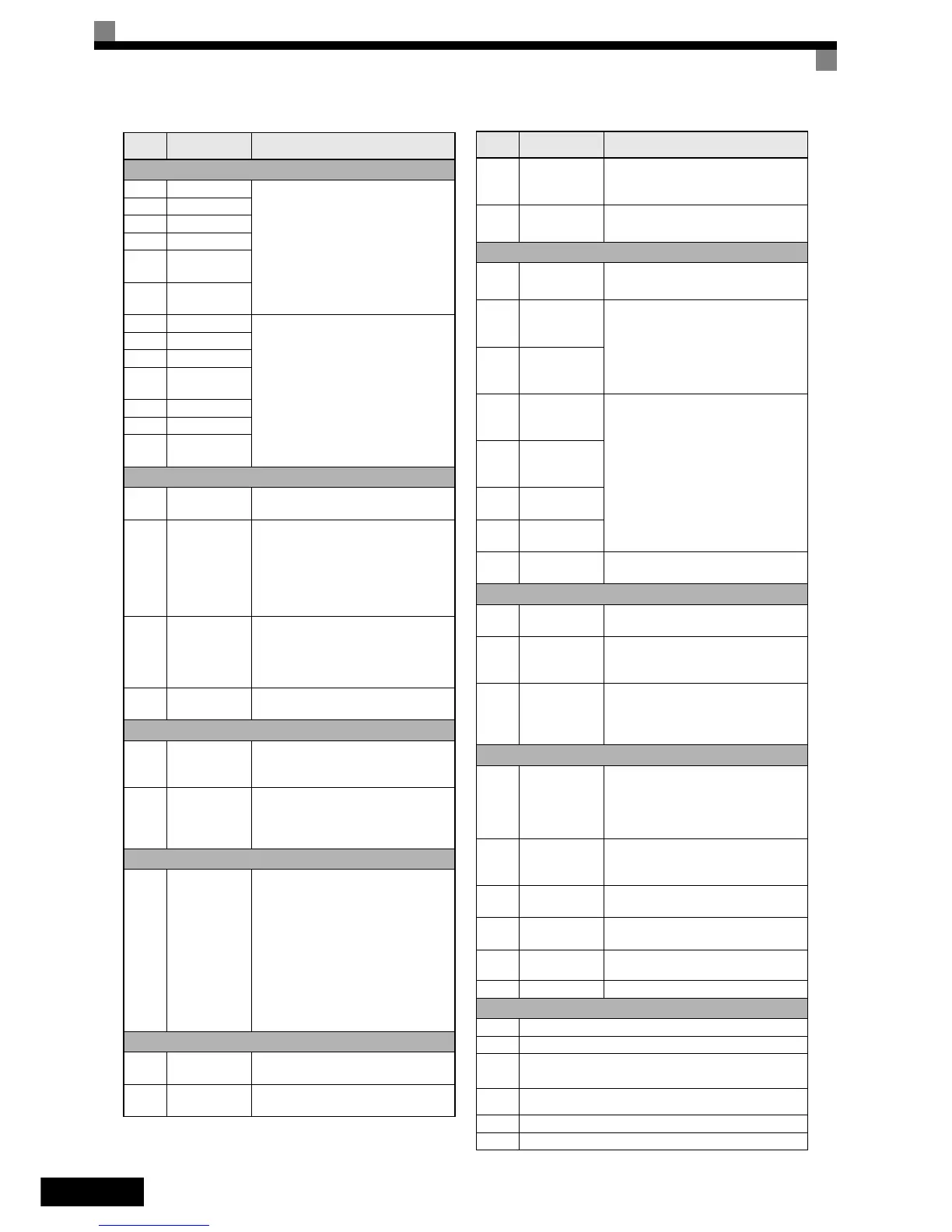

Speed Reference Slip Compensation

S2-01

Motor rated

speed

Sets the motor rated speed.

S2-02

Slip compensa-

tion gain in

motoring mode

Sets the slip compensation gain in motor-

ing mode. Can be set for leveling accu-

racy improvement.

S2-03

Slip compensa-

tion gain in

regenerative

mode

Sets the slip compensation gain in regen-

erative mode.

It can be used to improve the

leveling accuracy.

Special Functions Setup

S3-01

Short-floor

function selec-

tion

Enables or disables the short floor opera-

tion function

0:disabled

1:enabled (Standard)

2:enabled (Advanced)

S3-04

Nominal/Lev-

eling speed

detection level

Nominal/Leveling speed detection level

when multispeed inputs are used. (d1-

18=0/3)

S3-08

Output phase

order

0:Output phase order is U-V-W

1:Output phase order is U-W-V

S3-13

Traction sheave

diameter

Sets the diameter of the traction sheave

for m/s display units.

S3-14 Roping Ratio

1:1:1

2:1:2

S3-15 Gear Ratio Sets the mechanical gear ratio.

Monitor Data

U1-01 Frequency reference in Hz/rpm

U1-02 Output frequency in Hz/rpm

U1-03 Output current in A

U1-05 Motor speed in Hz/rpm

U1-06 Output voltage in VAC

U1-07 DC bus voltage in VDC

Param.

Num.

Name Description

Loading...

Loading...