86

Configuration of Function Blocks Section 3-1

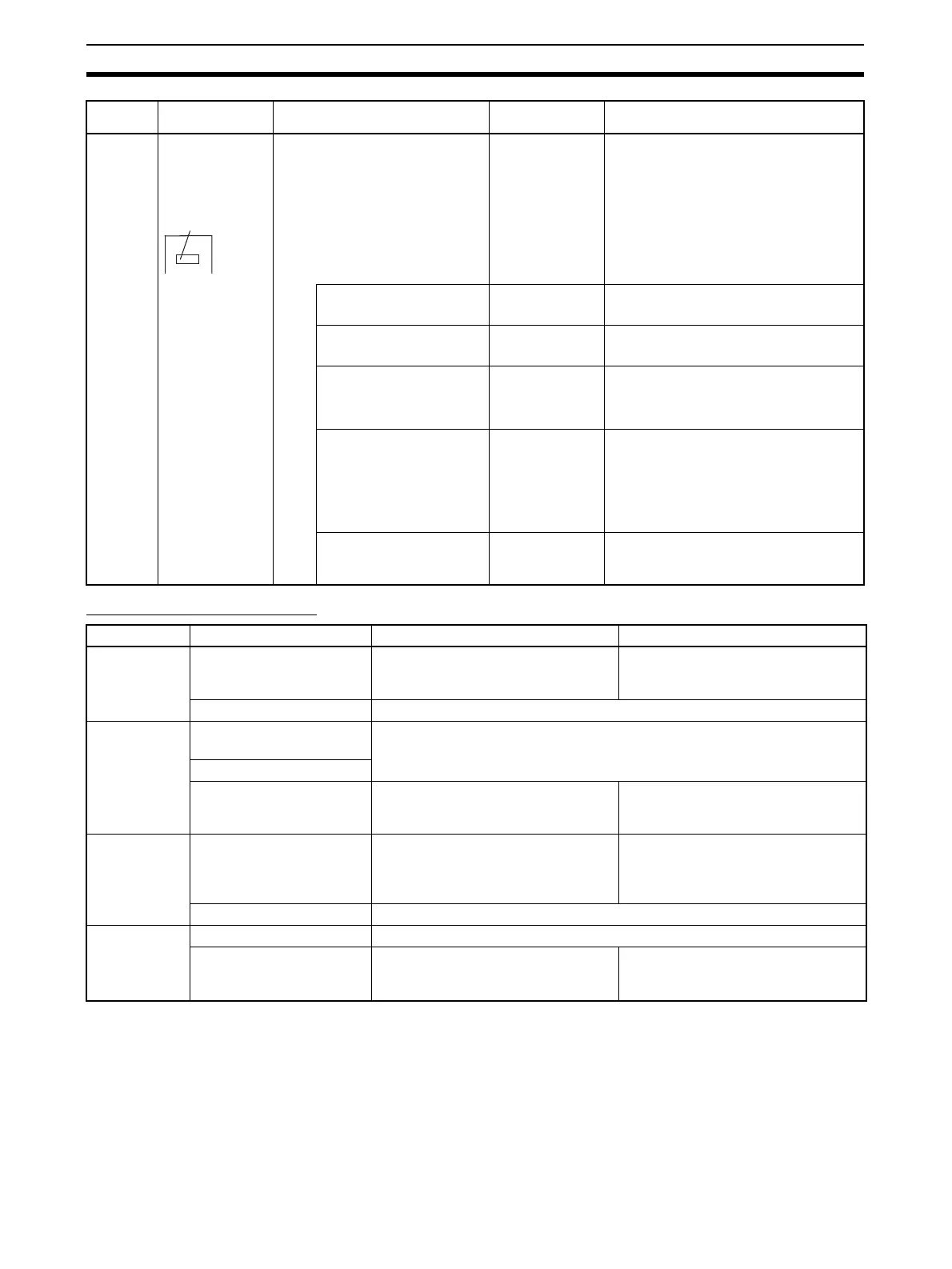

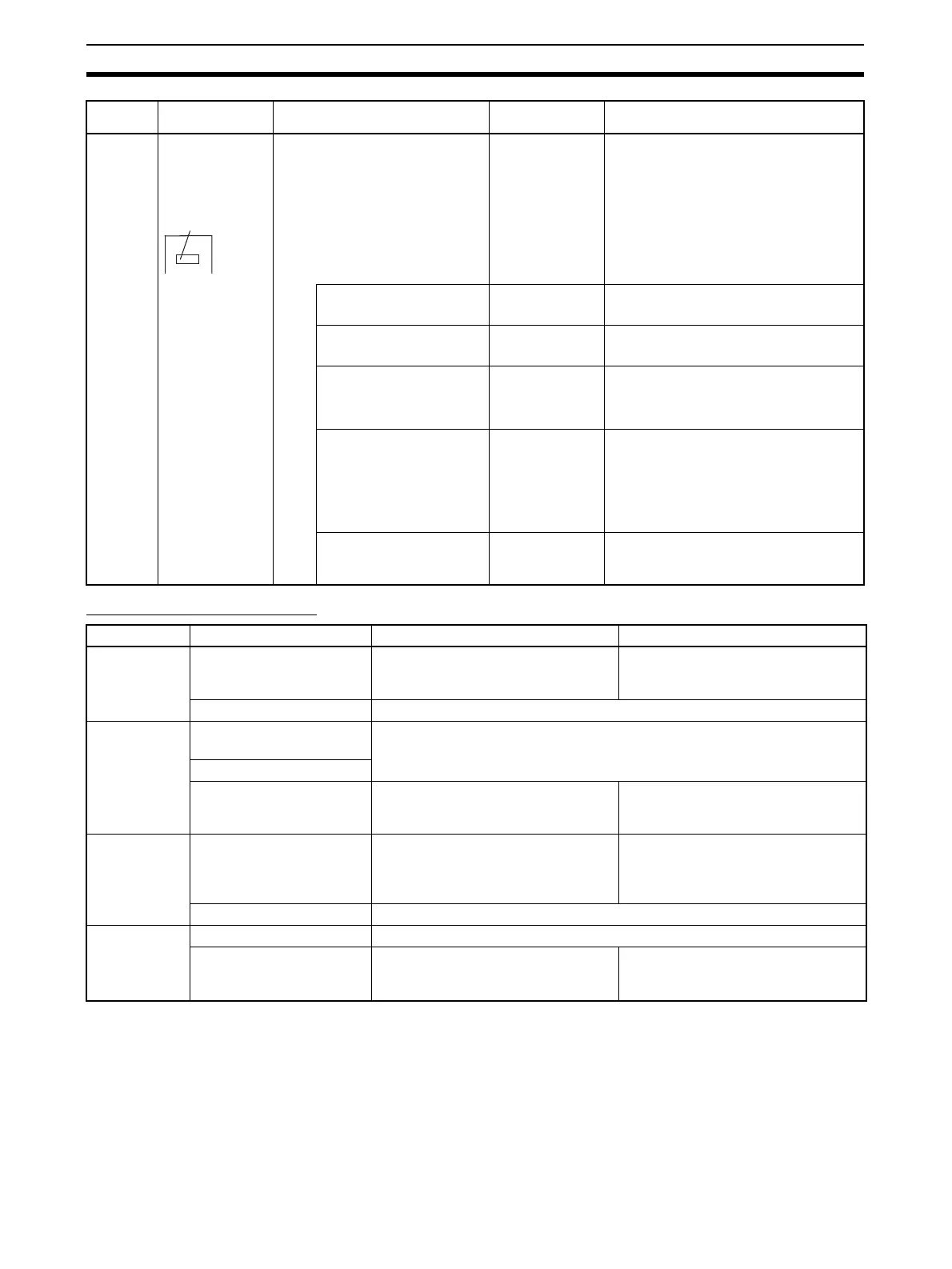

Field Input/Output blocks

Note Conventions Used in Describing ITEMs

Refer to the Function Block Reference Manual.

The Function Block Reference Manual defines reading and writing methods

according to the following four methods as one of R: Read, W: Write, or R/W:

R/W-enabled.

Parameter Basically, no sym-

bol in block dia-

gram (expressed

as follows in some

cases as an expla-

nation)

This is internal data upon which nei-

ther the above-described analog

input/output nor contact input/output

operations are performed.

There are two types of parameters:

parameters whose value can be

changed by one or a combination of

the methods 1) to 4) below, and

parameters whose value cannot be

changed by any of the following

methods (only indicated) in 5) below.

1) Parameter value can be

changed by CX-Process Tool

High alarm setting

(ITEM009) of the

Basic PID block

Set in CX-Process Tool.

2) Parameter value can be

changed using SCADA software.

Local Set Point set-

ting (ITEM023) of the

Basic PID block

Set in SCADA software.

3) Parameter value can be

changed by the Constant ITEM

Setting block (Block Model 171)

or the Variable ITEM Setting

block (Block Model 172).

Proportional band

setting (ITEM054) of

the Basic PID block

Constants or variables (analog signals) are written

according to the write destination of the Constant

ITEM Setting block (block number 171) or the Vari-

able ITEM Setting block (block number 172).

4) Parameter value can be

changed by the

Sequence

Table block (Block Model

302) or

Step Ladder Program

block (Block Model 301) or the

Contact Distributor block (Block

Model 201).

Auto/Manual switch

(ITEM086) of the

Basic PID block

This data is set according to the Sequence Table

block (Block Model 302) or Step Ladder Pro-

gram block (block number 301) or the Contact Dis-

tributor block (block number 201).

Note: Only “parameters” that are also “contact

inputs” (ITEMs whose ITEM type is specified as

“contact input/parameters” in the Function Block

Reference Manual)

5) Indication only (by Step Lad-

der Program)

PV execution error

indication (ITEM019)

of the Basic PID

block

Cannot be set

Function ITEM type Description Setting method

External ana-

log input

Specification of external

analog input

Analog signals are received from the

Analog Input Unit having the speci-

fied unit number.

Specify the unit number of the Analog

Input Unit.

Analog output Same as regular analog output ITEM

External ana-

log

output

Analog input connection

information

Same as regular analog input ITEM

Analog input

Specification of external

analog output

Analog signals are sent to the Analog

Output Unit having the specified unit

number.

Specify the unit number of the Analog

Output Unit.

External con-

tact input

Specification of external

contact input

Contact signals are received from the

Contact Input Unit allocated to the

leading specified CIO (channel I/O)

Area.

Specify the leading CIO (channel I/O)

Area allocated to the Contact Input

Unit.

Contact output Same as regular contact output ITEM

External con-

tact

output

Contact input Same as regular contact input ITEM

Specification of external

contact output

Specify the leading CIO (channel I/O)

Area allocated to the Contact Output

Unit.

Contact signals are sent to the Basic

I/O Unit allocated to the leading spec-

ified CIO (channel I/O) Area.

ITEM type Block diagram

symbol

Description Example Setting method

×××

ITEM numbe

Loading...

Loading...