65

How to Use Function Blocks for Specific Operations Section 1-4

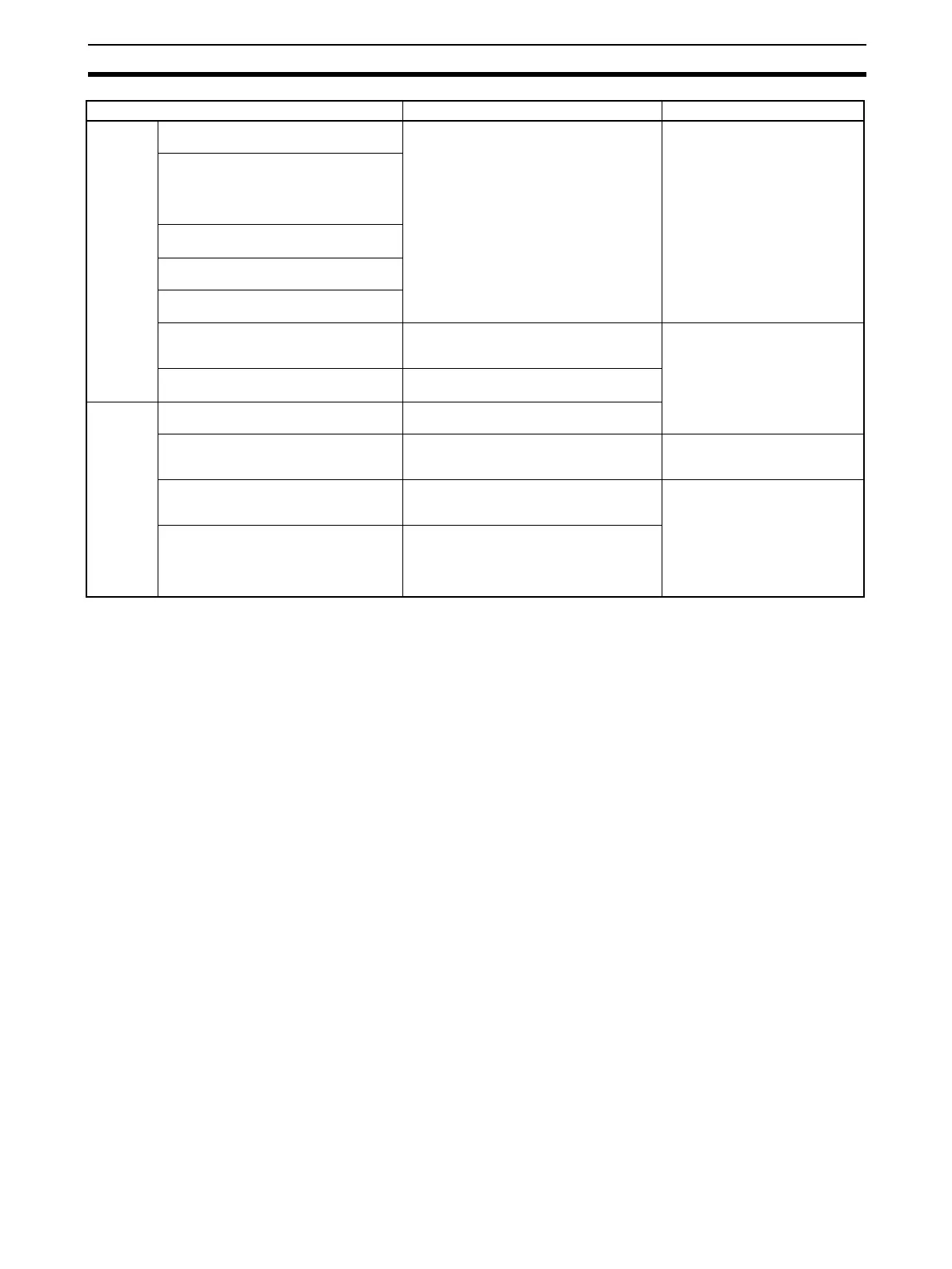

Sequence

control

AND, OR and other logical operations on

the Loop Controller

Use the Sequence Table block (Block Model

302) or Step Ladder Program block (Block

Model 301).

Use the Internal Switch block (Block Model

209).

Appendix A How to Use the Step

Ladder Program Block, Appendix

B Step Tables, and Function

Block Reference Manual

One-shot contact output of the ON input

state when the contact state changes

from OFF to ON and vice versa only in 1-

operation cycles (system common opera-

tion cycle)

Constantly ON contacts and other system

contacts

Step progression control and other con-

trol on the Loop Controller

Acceptance of bits in the Step Ladder

Program

Execution of special processing at each

fixed cycle longer than operation cycle in

Step Ladder Program

Generate a fixed cycle timing signal by the

Clock Pulse block (Block Model 207).

Function Block Reference Manual

Execution of timers/counters on the Loop

Controller

Use the Timer block (Block Model 205) and

the Counter block (Block Model 208).

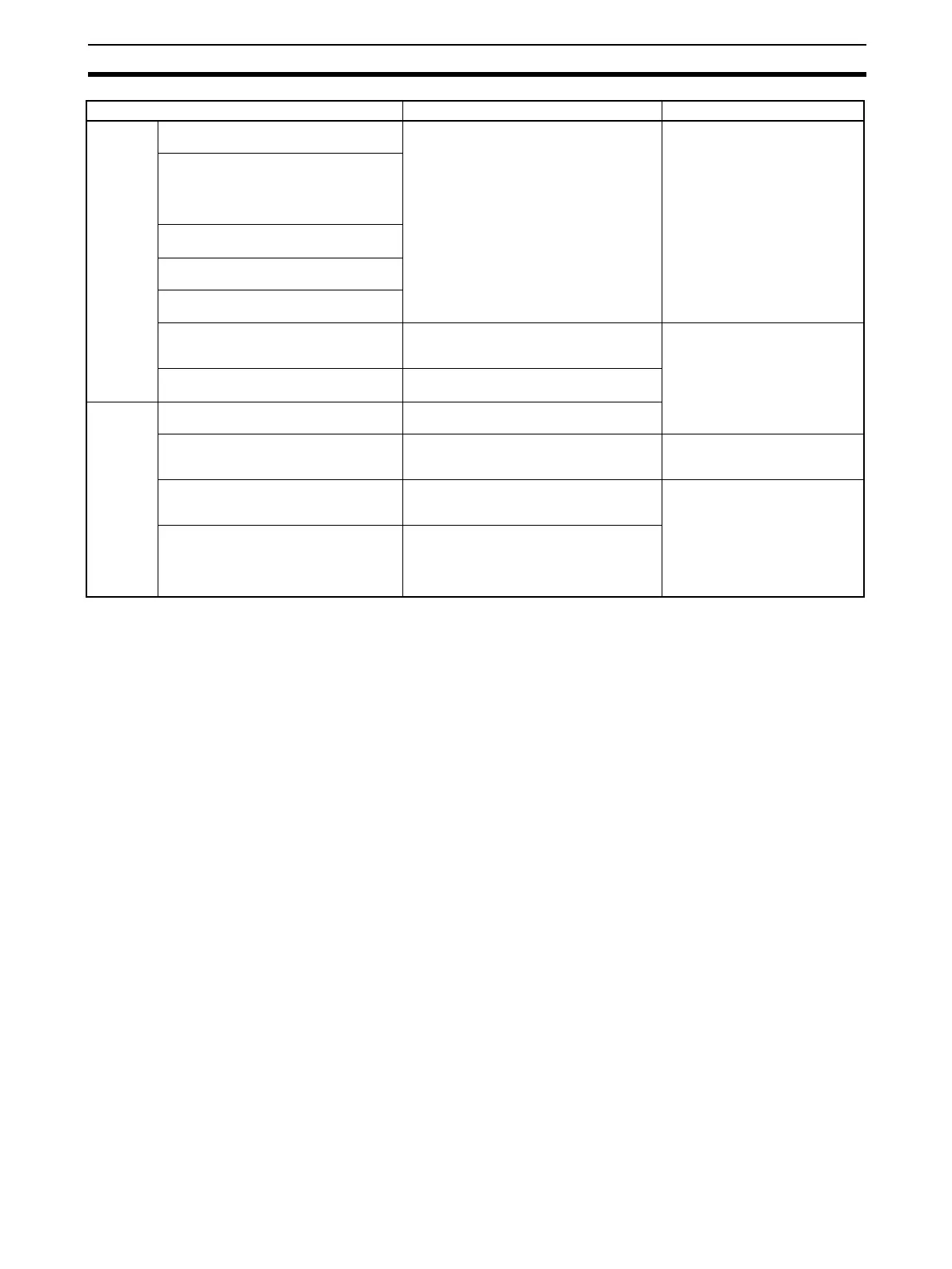

Constant

set-

ting/selec-

tion

Constant transmission of constants as

analog signals

Use the Constant Generator block (Block

Model 166).

Setting of constants to specified ITEMs

under certain conditions

Use the Constant Item Setting block (Block

Model 171).

3-1 Configuration of Function

Blocks and Function Block Refer-

ence Manual

Selection of one of multiple constants and

transmission of that constant as an ana-

log signal

Use the Constant Selector block (Block

Model 165).

Function Block Reference Manual

Changing PID constants and other

parameters in stages according to a pro-

cess value (e.g., temperature).

Use the Level Check block (Block Model

210) and the Constant ITEM Setting block

(Block Model 171) together to change

parameters for other blocks according to the

level.

To perform this specific operation Perform the following See page:

Loading...

Loading...