_______________________________________________________________________________________

ORVED S.P.A Rev.01 – 09/2019 – cod. 1500735-00EN – User Manual for

IDEA

vacuum packing machines

Pag. 58 a 76

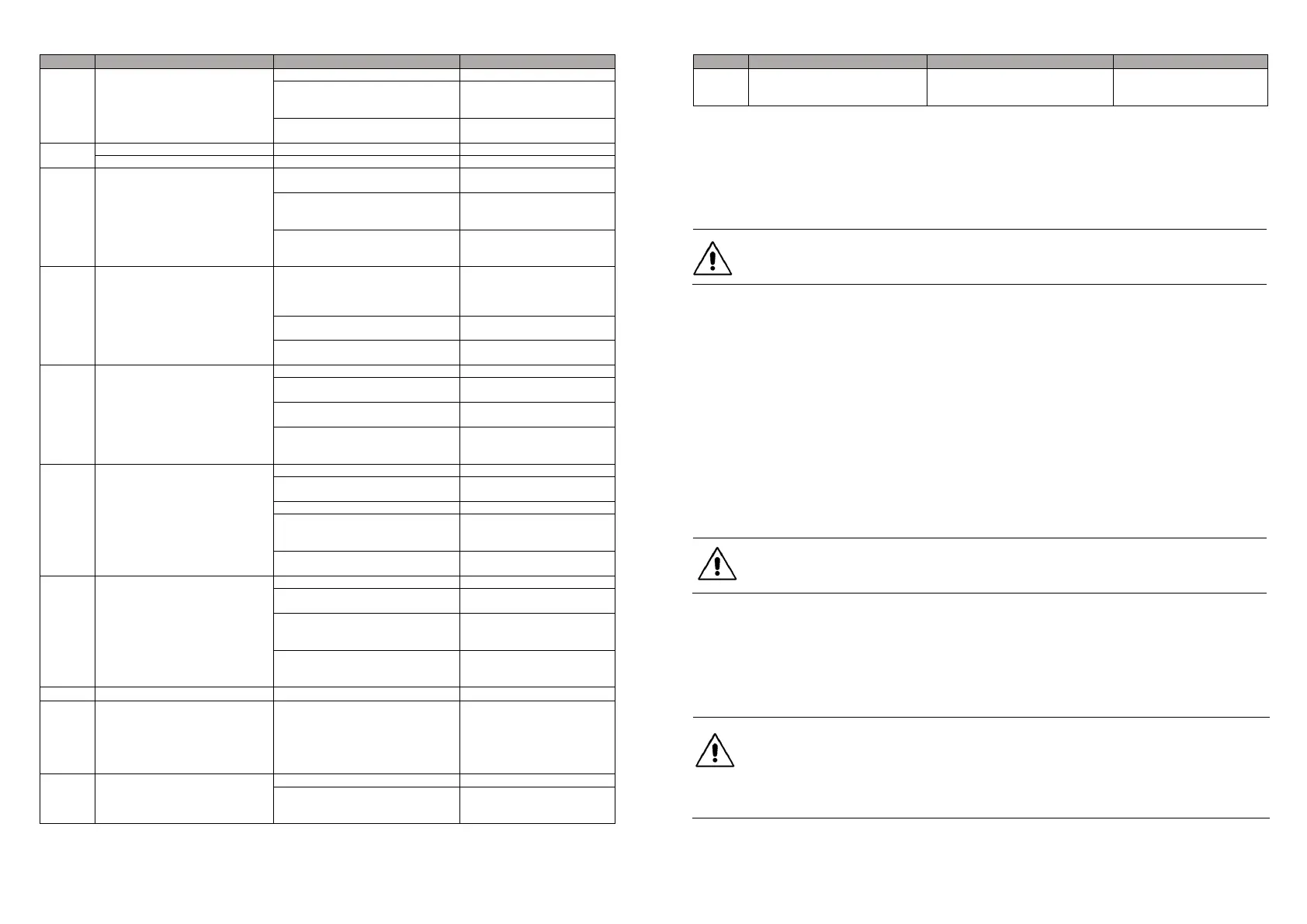

ERRORE PROBLEM POSSIBLE CAUSES SOLUTION

Defective bag Replace the bag

Dirty bag open

Use a new bag and avoid

dirtying the opening

with oil, grease, etc.

Bag too big or too small compared

to product size.

Choose a bag size suitable

for product dimensions.

3

Sealing shows burns and bubbles Sealing time too long Diminish the sealing time

Narrow or irregular sealing Sealing time too short Increase the sealing time

4

Insufficient vacuum in the

chamber.

Insufficient vacuum set

Increase the value level using

UP and DOWN

Insufficient vacuum pump

performance

• Check the oil.

• Check the pump exhaust

filter.

Worn cover gasket

Replace the cover gasket

(contact the authorised

service center)

5

Machine does not create vacuum

in the chamber.

Insufficient pressure exerted on

Plexiglas lid during appliance start

up

Lower cover with both hands,

exerting more

pressure.

For appliance provided with gas

option: gas function active

Deactivate the gas function

Pump does not work

Contact the authorised

service center

6

The machine does not seal.

Dirty sealing bar contacts Clean contacts

Disconnected sealing bar contacts

Restore connections (contact

the authorised service center)

Broken sealing bar wire

Change the wire (contact

the authorised service center)

Defective sealing bar lifting piston

Replace the bar lifting piston

(contact the authorised

service center)

7

Poor sealing

Dirty sealing bar Clean the sealing bar

Insufficient sealing time compared

to bag thickness

Increase the sealing time

Worn Teflon band cover Change the Teflon band

Excessive gas percentage (close to

90%) with respect to the packaged

product

Reduce the gas injection

Upper bar silicone worn

Change the upper bar

silicone

8

Insufficient gas quantity in the bag

Insufficient gas injection Increase the gas injection

Gas bottle pressure insufficient

Adjust the gas pressure on

cylinder to 1 bar

Gas nozzle not inserted in the bag

open part

Reposition bag by inserting

gas nozzle in the bag open

part

Gas bottle valve or pressure reducer

closed

Open gas bottle valves and

adjust pressure reducer to 1.0

bar

9

Lid opens during GAS cycle. Gas volume too high Reduce the GAS injection

10

Vacuum cannot be created in

containers

Container lid badly positioned or lid

valve open

Reposition the container lid,

making sure the gasket is in

good condition and inserted

in its seat and the suction

valve on the lid is in the

open position.

11

Plexiglass lid does not close

Worn cover gasket Replace the cover gasket

Hinges misalignment

Adjust the cover hinge

(contact the authorised

service center)

_______________________________________________________________________________________

ORVED S.P.A Rev.01 – 09/2019 – cod. 1500735-00EN – User Manual for

IDEA

vacuum packing machines

Pag. 59 a 76

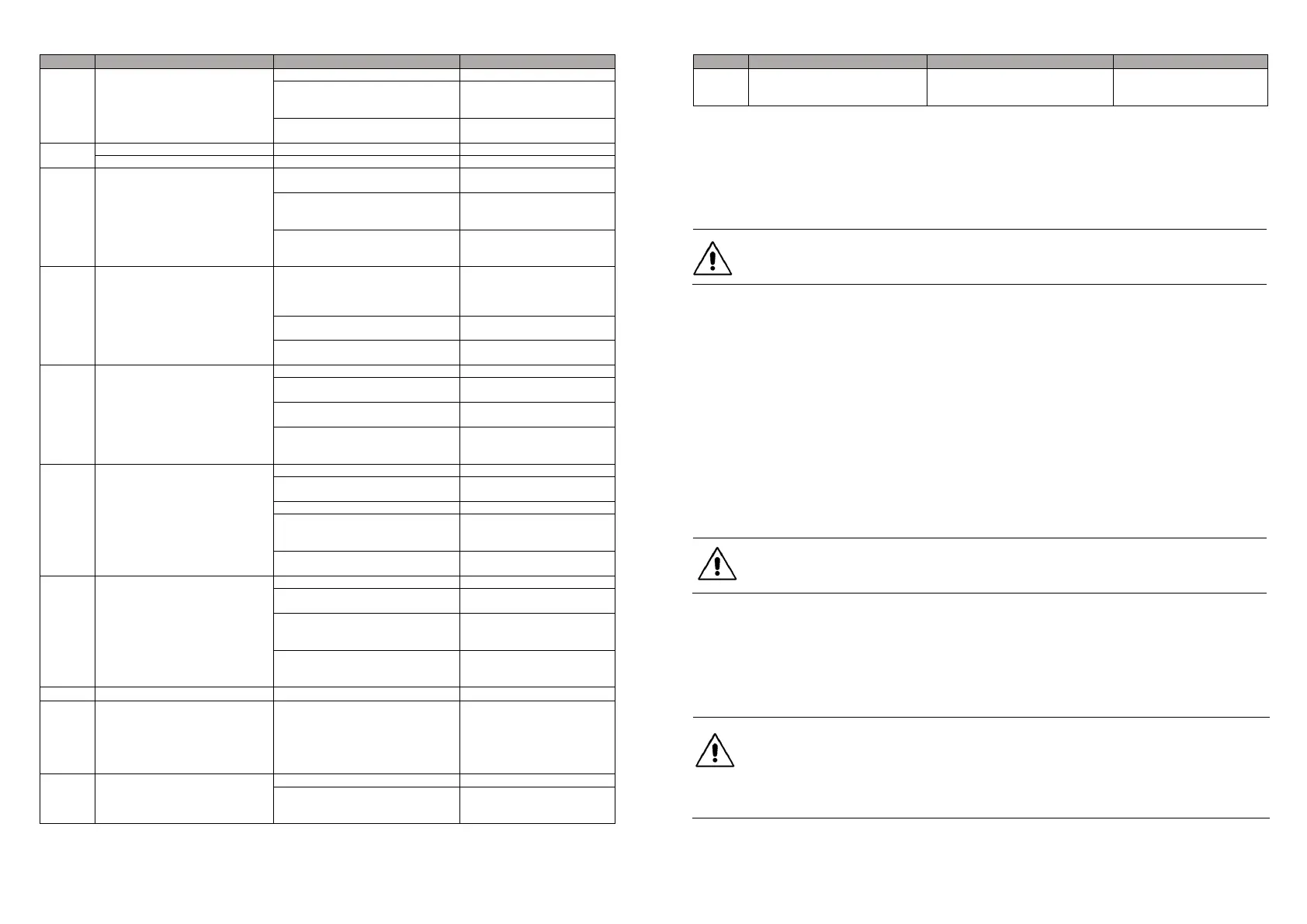

ERRORE PROBLEM POSSIBLE CAUSES SOLUTION

Damaged gas spring

Replace the gas spring

(contact the authorised

service center)

16 INSTALLATION

16.1 safety Instructions

This manual is an integral part of the product and provides all indications necessary for correct

installation, use and maintenance of the appliance.

The user and installer must carefully read and always refer to this manual; Moreover, it must be

kept in a place that is known and easily accessible for all authorized operators (instalator, user,

maintainer)

Do not touch the machine with bare, damp or wet hands or feet or without suitable protections (gloves and

shoes).

Do not insert screwdrivers, kitchen instruments or anything similar between the guards, openings

and moving parts of the machine.

The appliance is only intended for the use which it was designed for, i.e. for vacuum packaging foodstuffs.

All other uses shall be considered improper and potentially hazardous.

The manufacturer declines any responsibility and any warranty obligation for any damage to appliances,

persons or properties, due to:

• Installation not correct and/or not compliant with the current regulations;

• Modifications or interventions not specific for the machine model;

• Use of non-original spare parts or parts non-specific for the model;

• Failure to comply, even partially, with the instructions in this manual;

• Non-compliance, during the installation, of the accident prevention regulations and the current laws.

16.2 INTRODUCTION

Installation must be carried out by authorized and specialized personnel only, following strictly

instructions and provisions in this manual.

• Before installing the appliance, make sure any pre-existing electrical systems comply with the law and

correspond to the specifications shown on the ID plate of the appliance being installed (V, kW, Hz, and

available power).

• The installer must also check for any fire prevention.

• The Manufacturer declares the conformity to European current regulations.

• Before carrying out any operation, make sure the appliance is disconnected from the mains

• Do not pull the power cord, to disconnect the machine.

CAUTION! Handling of the machine must be performed using protective gloves and always by

two persons.

All components of the packaging must be disposed of according to the regulations in force in

the country where the equipment is being used. In any case nothing must be disposed of into the

environment.

CAUTION! The components of the packaging may be potentially hazardous for children and

pets. Make sure they do not play with them!

Loading...

Loading...