56

APEX615n Installation Guide

Motor Heatsinking

Performance of a servo motor is limited by the amount of current that can flow in the motor's coils without

causing the motor to overheat. Most of the heat in a brushless servo motor is dissipated in the stator - the outer

shell of the motor. The primary pathway through which you can remove the heat is through the motor's

mounting flange. Therefore, mount the motor with its flange in contact with a suitable heatsink.

Current foldback (I

2

T Limit) settings and APEX Series motor specifications assume that the motor is mounted

to a ten inch by ten inch aluminum plate, 1/2 inch thick (250mm x 250mm x 13mm). To get rated

performance in your application, you must mount the motor to a heatsink of at least the same thermal

capability. Mounting the motor to a smaller heatsink may result in decreased performance and a shorter service

life. Conversely, mounting the motor to a large heatsink can result in enhanced performance. You can also use

a fan to blow air across the motor for increased cooling, if you do not get enough cooling by conduction

through the face flange.

Coupling the Motor

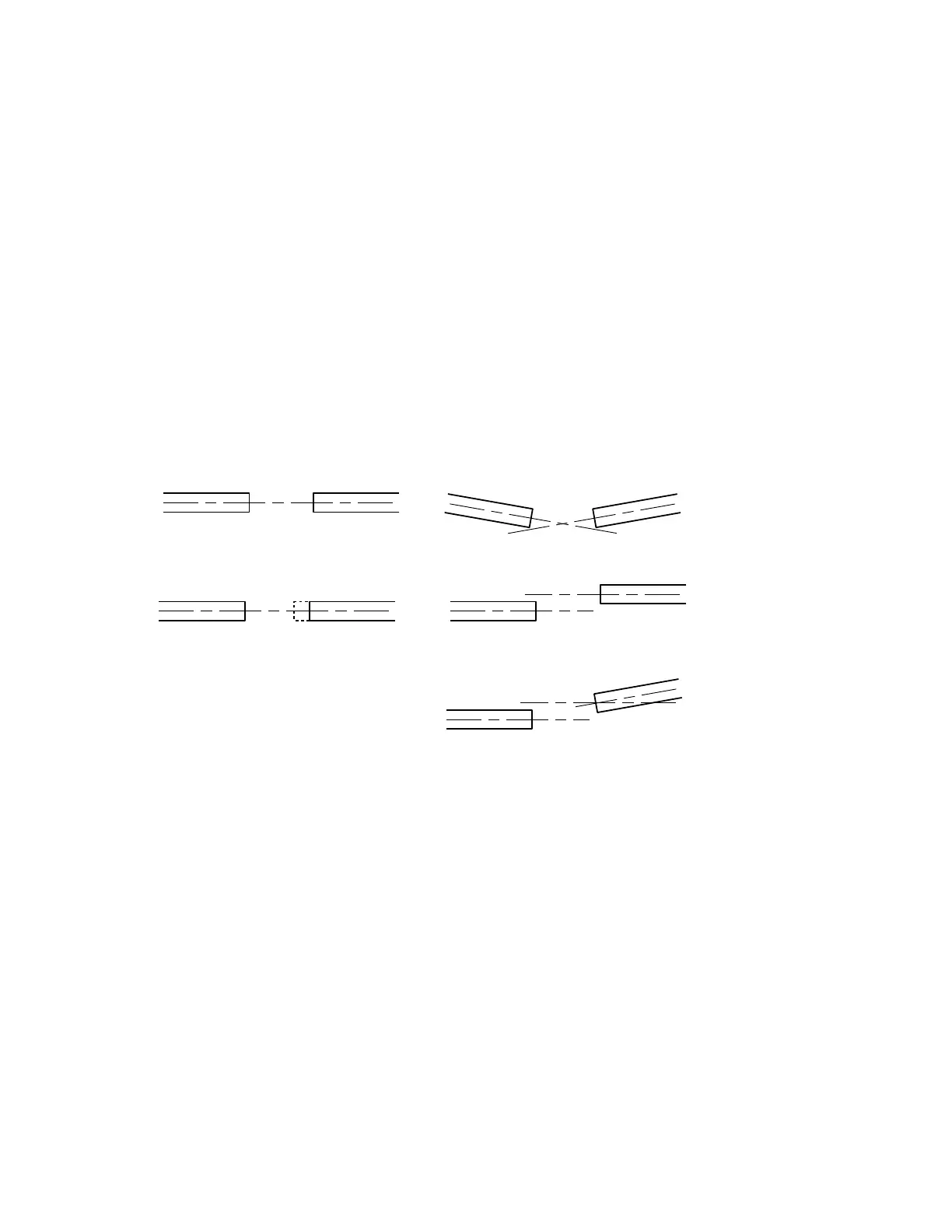

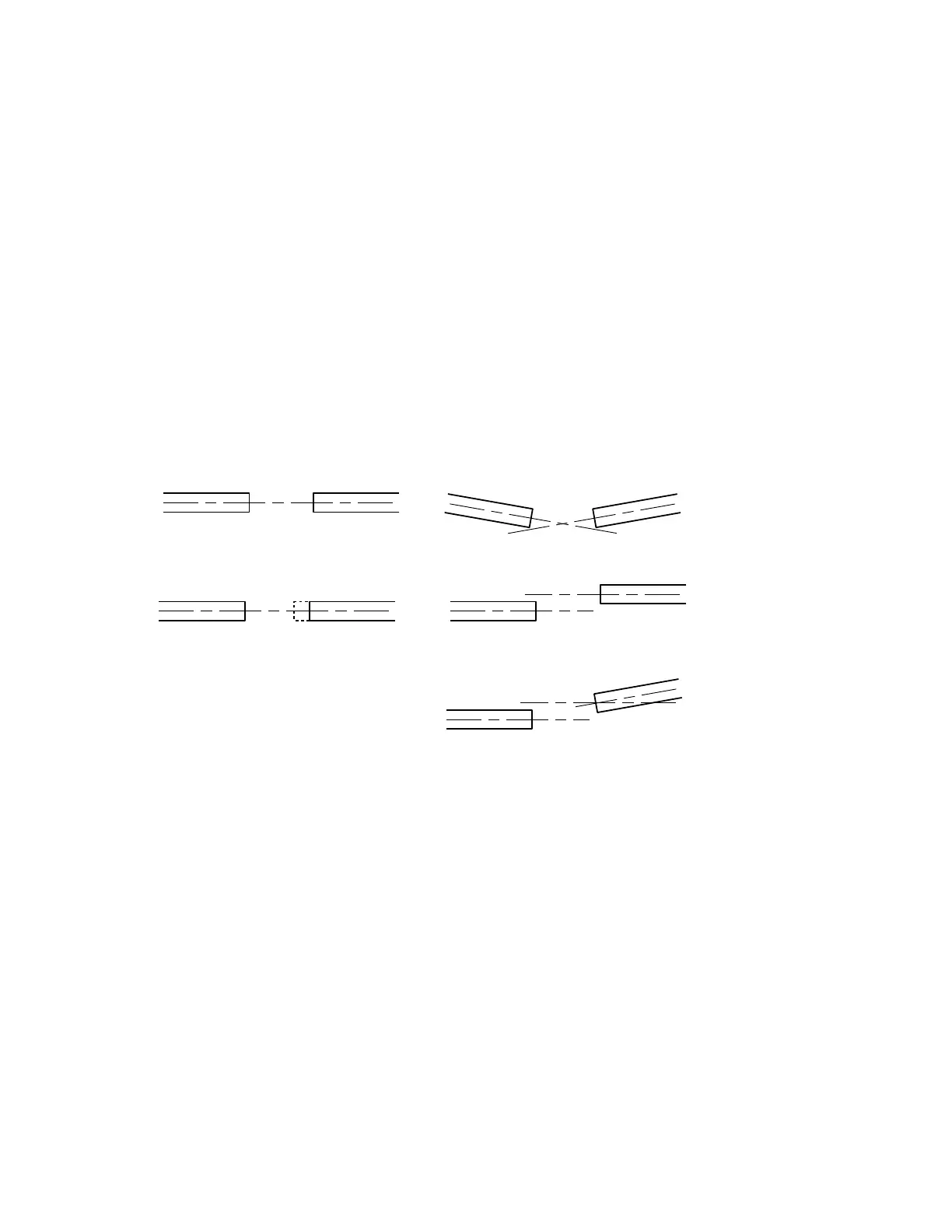

Align the motor shaft and load as accurately as possible. In most applications, some misalignment is

unavoidable, due to tolerance buildups in components. However, excessive misalignment may degrade your

system’s performance. The three misalignment conditions, which can exist in any combination, are illustrated

below. The type of misalignment in your system will affect your choice of coupler (described below).

Aligned

Parallel Misalignment

Combined Parallel & Angular Misalignment

End Float

Angular Misalignment

Your mechanical system should be as stiff as possible. Because of the high torques and accelerations of servo

systems, the ideal coupling between a motor and load would be completely rigid. Rigid couplings require

perfect alignment, however, which can be difficult or impossible to achieve, as shown above. In real systems,

some misalignment is inevitable. Therefore, a certain amount of flexibility may be required in the system. Too

much flexibility can cause resonance problems, however.

The type of misalignment in your system will affect your choice of coupler.

Single-Flex Coupling

Use a single-flex coupling when you have angular misalignment only. Because a single-flex coupling is like a

hinge, one and only one of the shafts must be free to move in the radial direction without constraint. Do not

use a double-flex coupling in this situation: it will allow too much freedom and the shaft will rotate

eccentrically, which will cause large vibrations and catastrophic failure. Do not use a single-flex

coupling with a parallel misalignment: this will bend the shafts, causing excessive bearing loads and

premature failure.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...