Chapter 2. Troubleshooting

63

Common Problems & Solutions

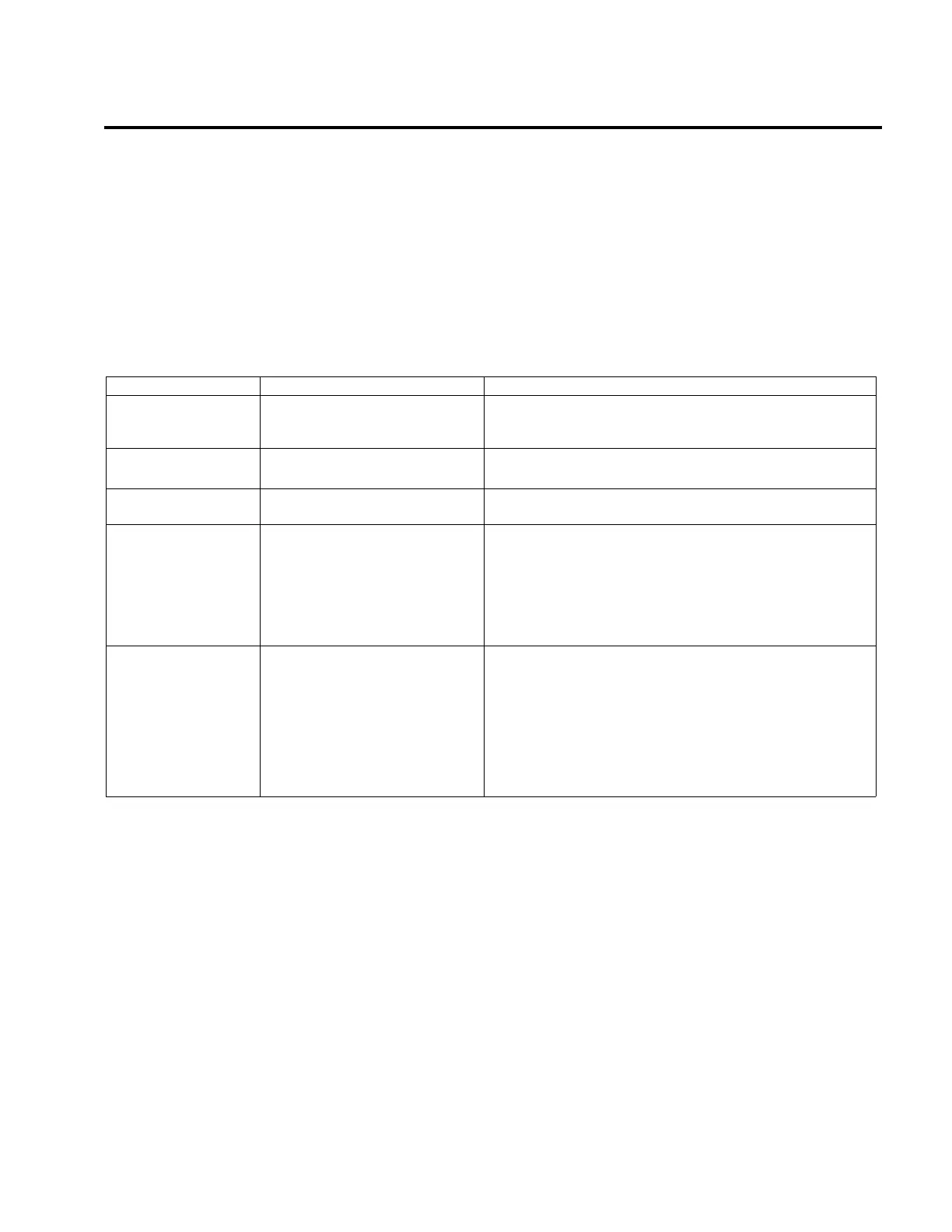

The following table presents some guidelines to help you isolate problems with your motion

control system. Some common symptoms are listed along with a list of possible causes and

remedies.

• Look for the symptom that most closely resembles what you are experiencing.

• Look through the list of possible causes so that you better understand what may be

preventing proper operation.

• Start from the top of the list of remedies and use the suggested procedures to isolate the

problem.

• Refer to other sections of the manual for more information on APEX615n set up,

system connections, and feature implementation. You may also need to refer to the

6000 Series Software Reference.

Problem Cause Solution

Erratic operation 1. Electrical Noise

2. Improper wiring

1. Reduce electrical noise or move the APEX615n away from noise

source (refer also to Appendix A)

2. Check wiring for opens, shorts, and mis-wired connections

LEDs:

DISABLE is red

1. Shutdown input active

2. Position error

1. Issue DRIVE1 command

2. Issue DRIVE1 command

LEDs:

ENABLE LED is off

1. No AC power 1. Check AC power

Missing counts from

feedback device

1. Improper wiring

2. Feedback device slipping

3. Feedback device too hot

4. Electrical noise

5. Feedback device frequency too high

1. Check wiring

2. Check and tighten feedback device coupling

3. Reduce encoder temperature with heatsink, thermal insulator, etc.

4a. Shield wiring (refer also to Appendix A)

4b. Use encoder with differential outputs

5. Peak encoder frequency must be below 1.2 MHz post-quadrature;

peak frequency must account for velocity ripple

No Motion 1. ENABLE LED off

2. Limits engaged

3. Improper wiring

4. Load is jammed

5. No torque from motor

6. Maximum position error exceeded

7. ENABLE IN input is not grounded to

GND

1. See Enable LED problems above.

2a. Move load off of limits or disable limits with LHØ

2b. If using soft limits, make sure LSCW>LSCCW

3. Check enable, fault, and limit connections.

4. Remove power and clear jam

5. See problem:

No Torque

6. Check to see if TAS bit #23 is set, and issue the DRIVE1 command

7. Ground ENABLE IN to GND and reset or cycle power

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...