Installer manual Autotrol Magnum 293 - 298 Logix 742-762 - Maintenance

Ref. MKT-IM-012 / D - 03.02.2022 71 / 110

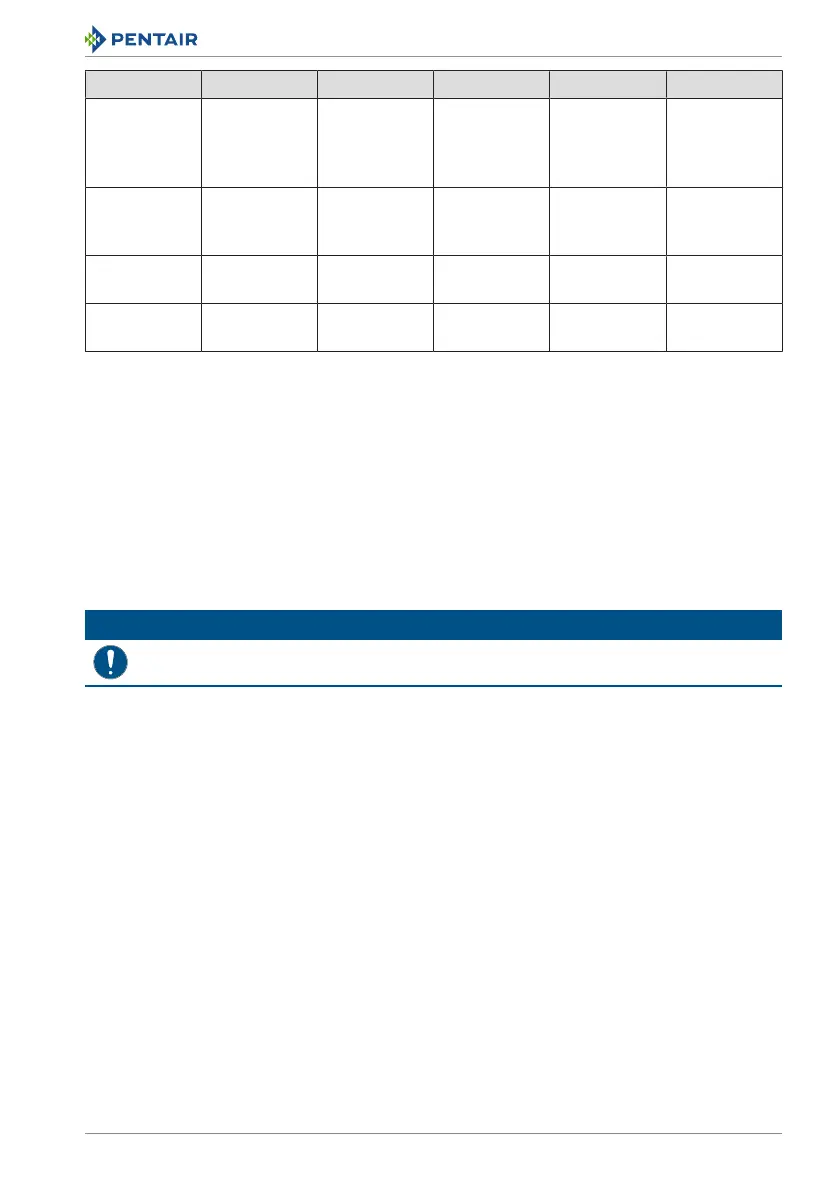

Items 1 year 2 year 3 year 4 year 5 year

External

Turbine (Cv

model, if

present)***

Check/ clean Check/ clean Check/ clean Check/ clean Replace

Turbine cable

(if turbine

present)

Check Check Check Check Replace

Valve

watertightness

Check Check Check Check Check

Valve to piping

watertightness

Check Check Check Check Check

* Electronical parts – durability strongly affected by power source quality and stability

** Elastomer durability is strongly affected by raw water concentration in chlorine and its derivate

*** Wear part

**** Cartridges tends to stick to valve body after some months in service and might be damaged

when unmounting. Prefer to remove cartridges only when it must be replaced. Cartridges must

not be unmounted for troubleshooting investigations but only when exchange is really required.

Report to chapter Magnum valve cartridge [

→

Page91] for complete troubleshooting guide and to

chapter Cartridge replacement [

→

Page85] for proper assembly/disassembly procedure.

9.3 298 CV / IT: General system inspection

Mandatory

Has to be done once a year at minimum.

9.3.1 Water quality

1. Check for raw water analysis and filter’s targeted contaminants concentration.

2. Check for treated water analysis and compare with raw water data.

9.3.2 Mechanical Checks

1. Inspect general condition of valve and associated ancillaries and check for any leaks, ensure

valve connection to piping is made with adequate flexibility as per manufacturer instruction.

2. Inspection of electrical connections, verify wiring connections and search for evidence of

overloading.

3. Verify settings of electronic timer, verify regeneration frequency, make sure the valve

configuration corresponds to the settings.

4. Check water meter, if present, report water meter settings and compare with previous

inspection.

5. Verify total water consumption compared to previous visit.

Loading...

Loading...