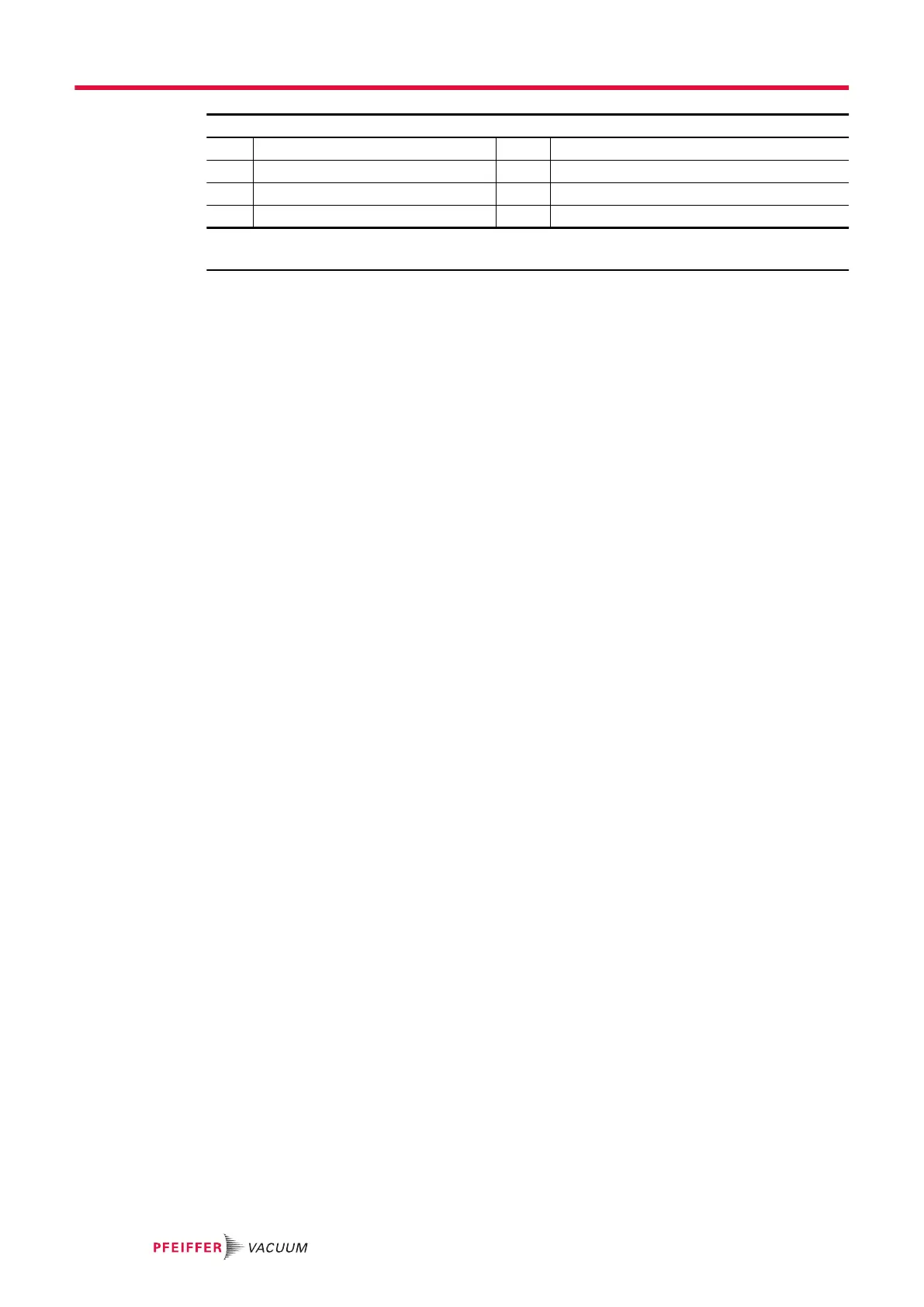

Components in the pumping installation

V1

1)

Fore vacuum isolation valve N2 Inert gas purge inlet

V2

1)

High vacuum isolation valve Turbo Magnetically levitated turbomolecular pump

V3

2)

Purge solenoid valve (option)

P

1)

Backing pump

V4

2)

Air inlet solenoid valve (accessory)

1) The supply, power supply and control of these components are the customer’s responsibility.

2) These solenoid valves are controlled via the electronic drive unit.

Pumping start-up procedure

Initial conditions:

Valves V3 and V4 are connected and controlled via the electronic drive unit.

Valves V1 and V2 are connected and controlled by the equipment.

The vacuum chamber and the pumping lines are at atmospheric pressure, the backing pump is stopped

and the valves are closed.

1. Start up the water-cooling circuit.

2. Send a pump ‘Start’ order via the HHR, Remote, serial link or fieldbus control panel:

–

The backing pump starts up and valves V1 and V2 open.

–

The turbomolecular pump starts to reach the selected speed: the green LED flashes at

90 %.

–

When the speed is reached, the LED is lit continuously.

3. Depending on the application, open the V3 purge solenoid valve by sending a ‘Purge’ order via

the HHR, Remote, serial link or fieldbus control panel.

The pumping operation is performed until the operating pressure for the application is reached.

Stand-by speed

The Stand-by speed is selected when the pump is stopped or rotating.

►

Send a ‘Stand-by’ order via Remote, serial link or fieldbus control panel or press the STD-BY key

of the HHR interface.

Temperature management (MT version pump)

►

Select the temperature setpoint via the HHR, serial link or fieldbus control panel.

For more information about temperature management, see chapter “Pump Temperature management

system”.

6.2.3 Restarting the pump after an emergency equipment stop

The equipment emergency stop manages the pump stop. To restart the pump after an emergency stop,

it is necessary to:

1. Make sure the pump has stopped (all LED are off).

2. Wait for pump rotor has stopped.

3. Correct the problem.

4. Unlock the emergency stop button on the equipment,

5. Start the pump by sending a ‘Start’ pump order via the control panel: the pump starts at the se-

lected speed.

Operation

26/60

Loading...

Loading...