22 PianoDisc Installation Guide

228CFX - PianoCD - iQ

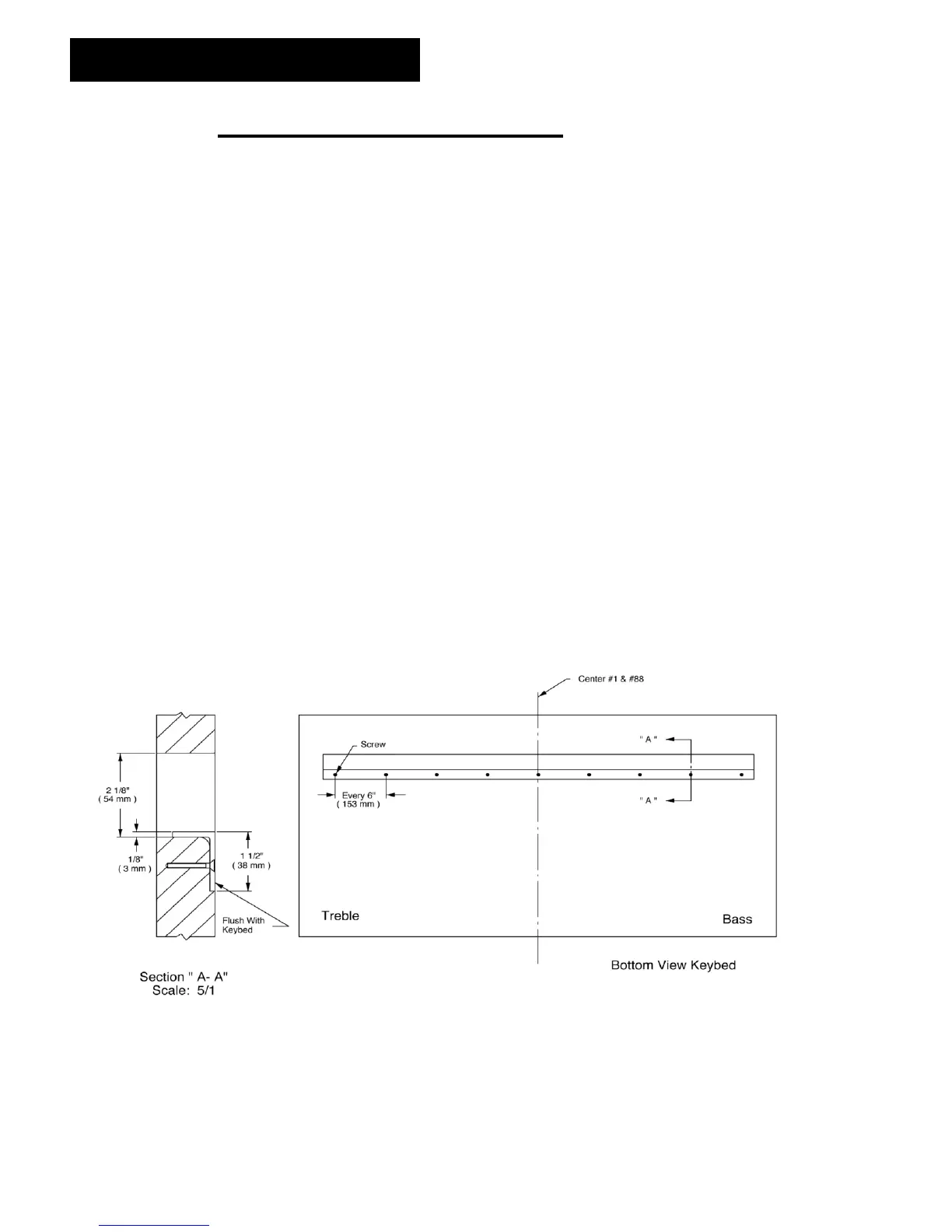

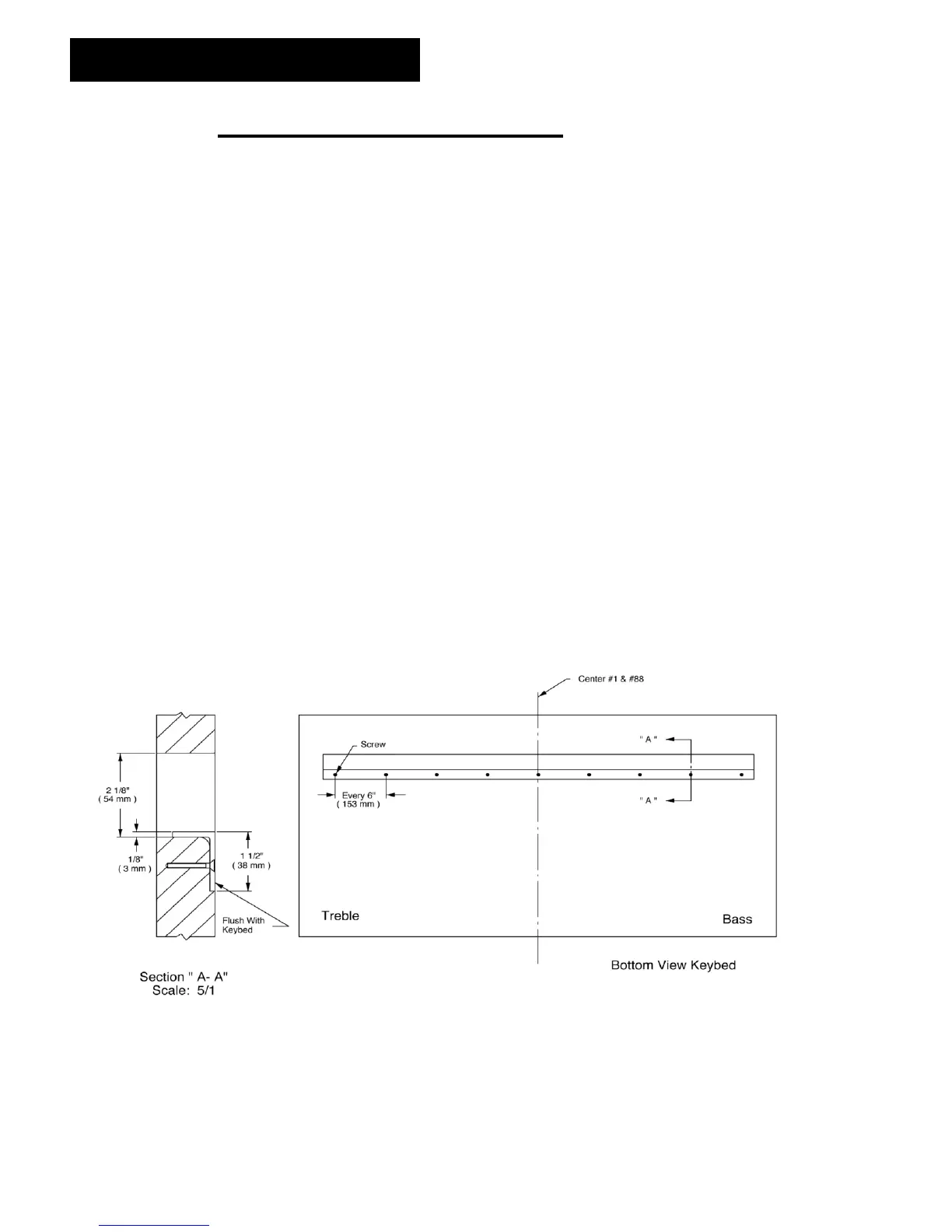

Step 12: Reinforce the keybed

Note: If the keybed is sectioned (as in some Steinways) or if the keybed is less

than 1 1/2” (38 mm) thick, we strongly recommend reinforcing the keybed after

cutting the slot. In weaker keybeds, this will greatly improve the stability of the

action regulation.

Note: On the plank style keybeds, the connecting point of the planks will most

likely be cut away when the slot is cut. It is advisable to locate and router out

the area for the angle iron support before cutting the solenoid slot. (See Fig. 9)

A. Prepare the reinforcement. Use a piece of 1/8" (3 mm) by 1 1/2" (38 mm)

angle iron and cut it to match the length of the slot.

• Drill screw holes in the angle iron at 6" (153 mm) intervals or into each plank so

that it can be secured to the bottom of the keybed.

• Also, use a countersink bit on the holes drilled to flush mount flat head screws.

B. Prepare the mounting location for the angle iron by routing out the

equivalent thickness and length along the bottom of the keybed. (See Fig.

9)

• This is so that the angle iron will not protrude from the bottom of the keybed,

allowing the rail cover to fit properly. Use a wood router for this purpose.

• Also, after routing for flush fit of angle iron, round off the edge of keybed to match

inside radius of angle iron. A router bit works well in making radius cut.

Figure 9

C. Paint and mount the angle iron by screwing it into the bottom of the keybed.

Make sure that the angle iron is flush with the bottom of the keybed.

Loading...

Loading...