The torque method for checking alternator belt tension is given as follows:

1. Apply a torque indicating wrench to the nut that attaches the pulley to the alternator and turn it in a

clockwise direction. Observe the torque shown on the wrench at the instant the pulley slips.

2. Compare the torque indicated in Step 1 with torque specified in the following chart. Adjust tension

accordingly.

— Note —

The higher tension specified for a new belt is to compensate for the initial stretch that

takes place as soon as it is operated. These higher tension values should not be

applied to belts which have previously been used.

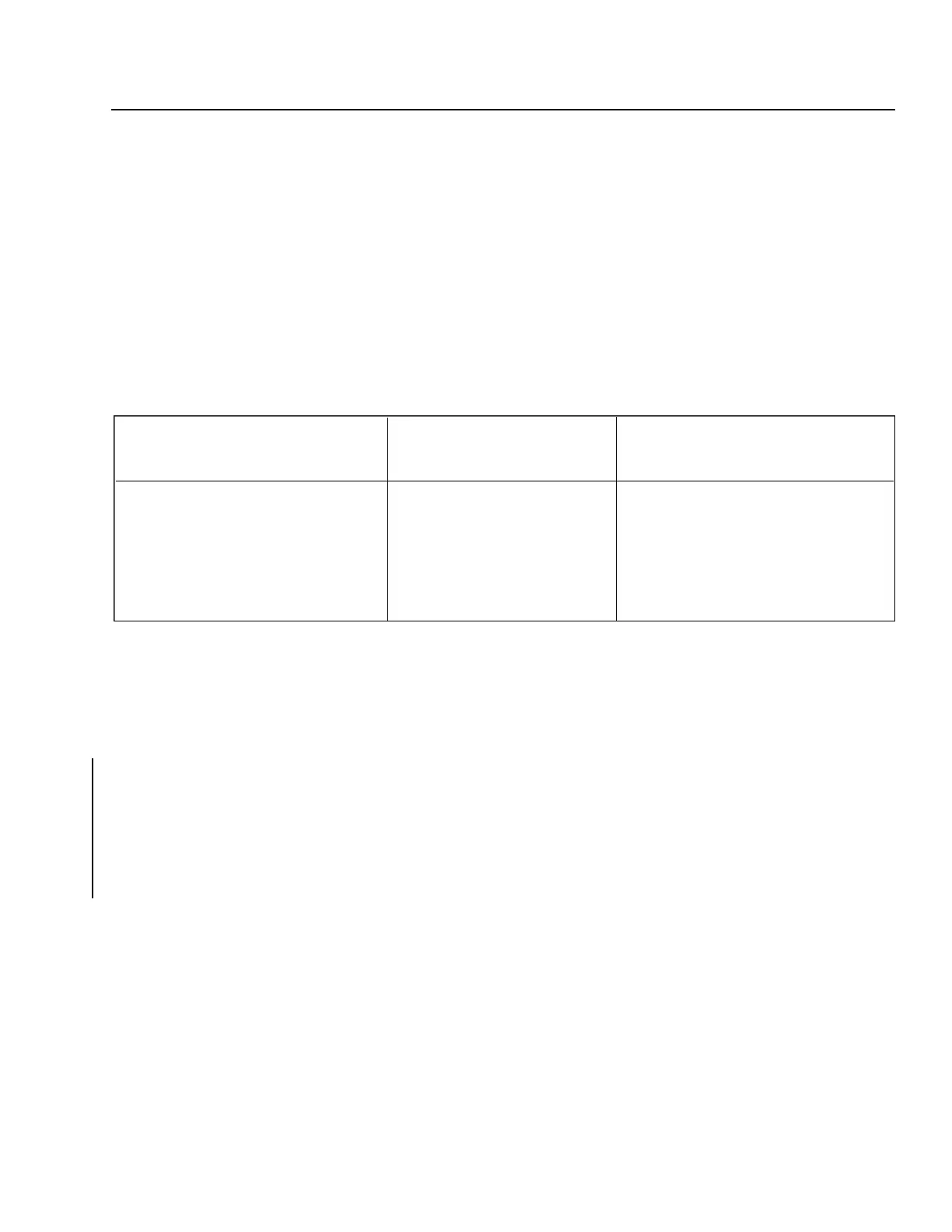

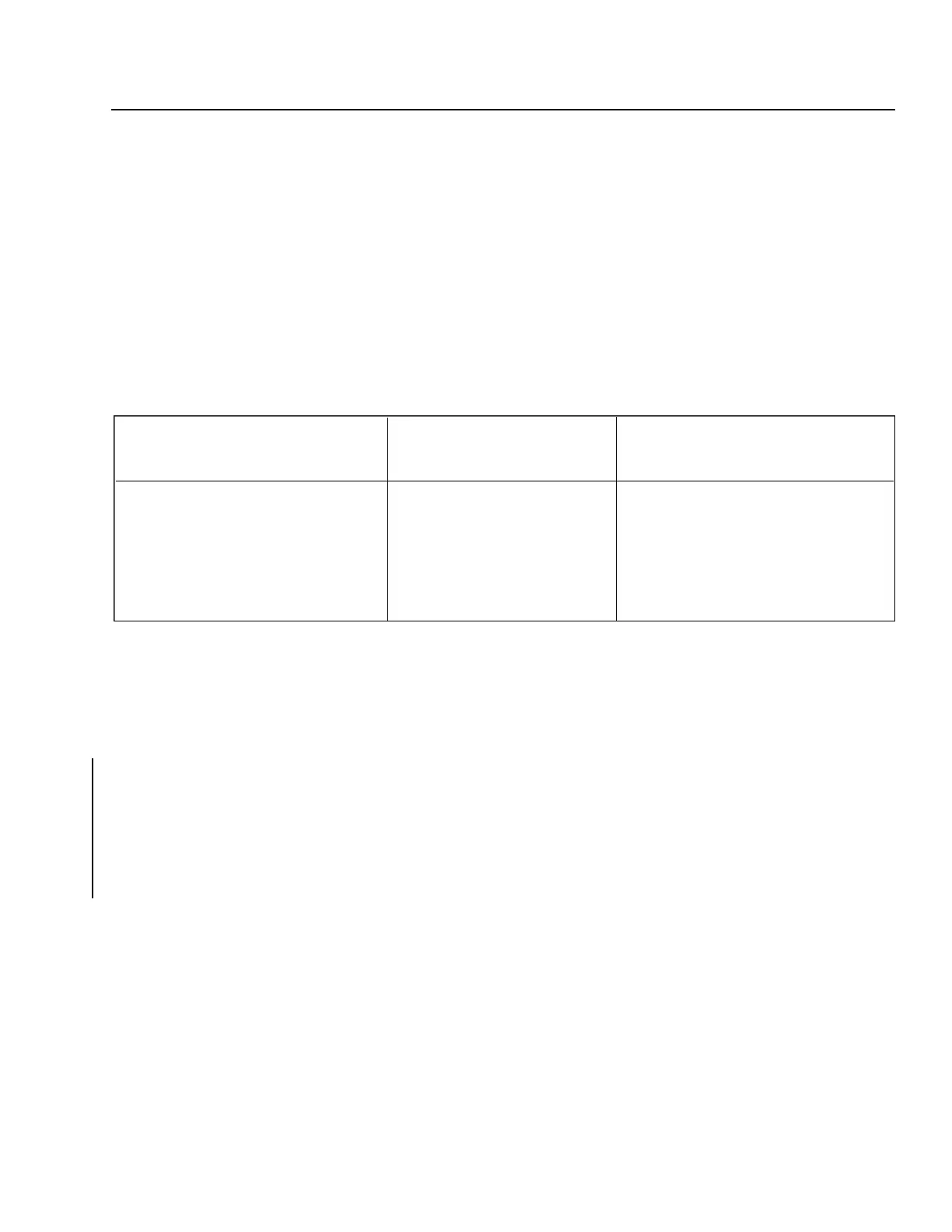

CHART 2403. ALTERNATOR BELT TENSION

BATTERY.

The battery is located in the nose of the aircraft and is accessible by opening the hinged fiberglass nose which

tips forward, and then removing the battery box cover. (Refer to Figure 24-2)

— Note —

In the past, aluminum cable was used in wiring the battery circuit, battery to ground,

battery to master relay, master relay to starter solenoid, starter solenoid to starter and

engine return ground wire to airframe. (See schematics for your airplane) If, during

inspection, a fault in the aluminum cable is found, Piper considers it mandatory that

the complete cable assembly be replaced with copper wire and suitable terminals.

Torque indicated at

Width of Belt Condition alternator pulley

3/8 inch New 11 to 13 ft-lbs

3/8 inch Used 7 to 9 ft-lbs

PA - 4 4 - 1 8 0 / 1 8 0 T

AIRPLANE MAINTENANCE MANUAL

2 4 - 3 1 - 0 3

Page 24-11

Revised: May 15, 1989

1I23

PIPER AIRCRAFT

Loading...

Loading...