MAINTENANCE

2.10

LUBRIC ATION, CONT.

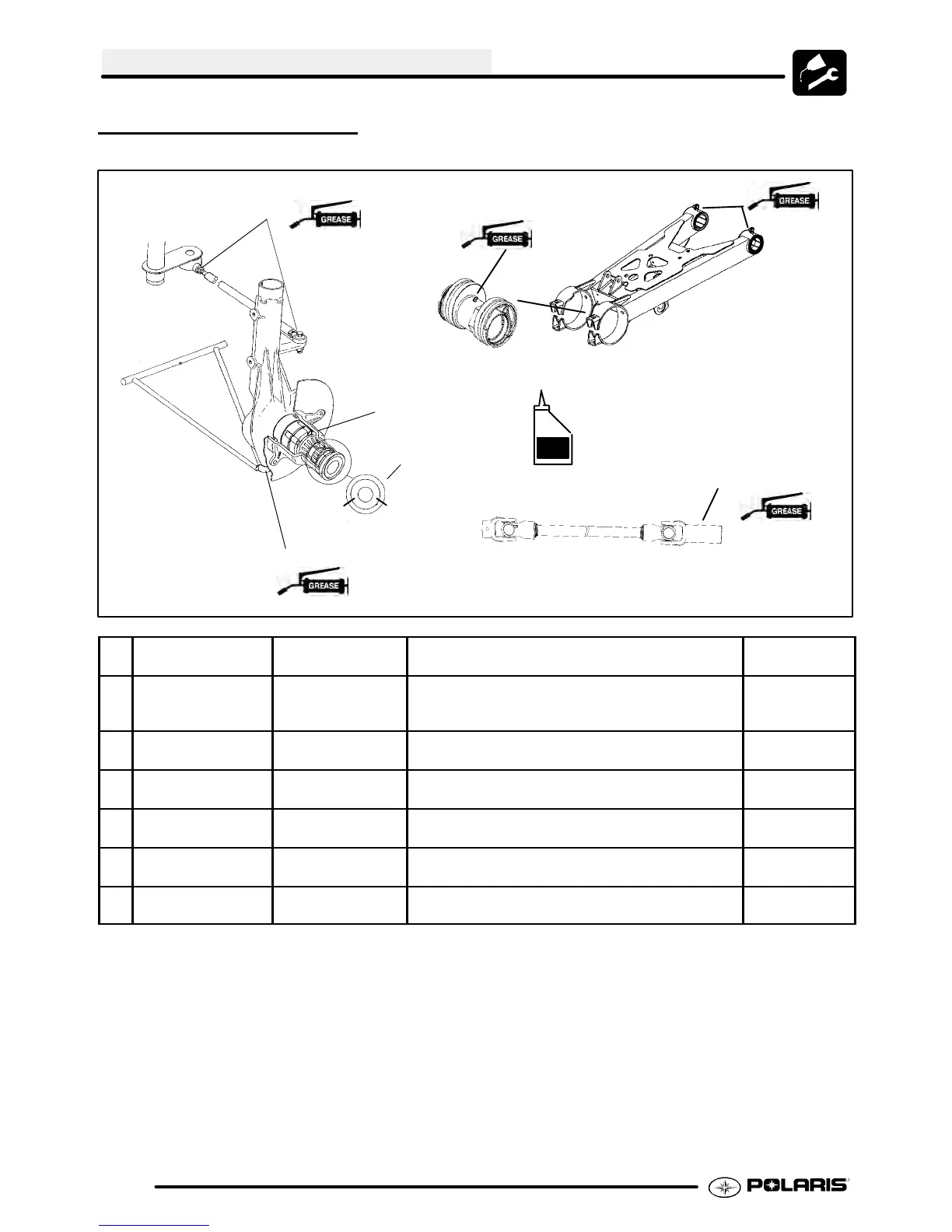

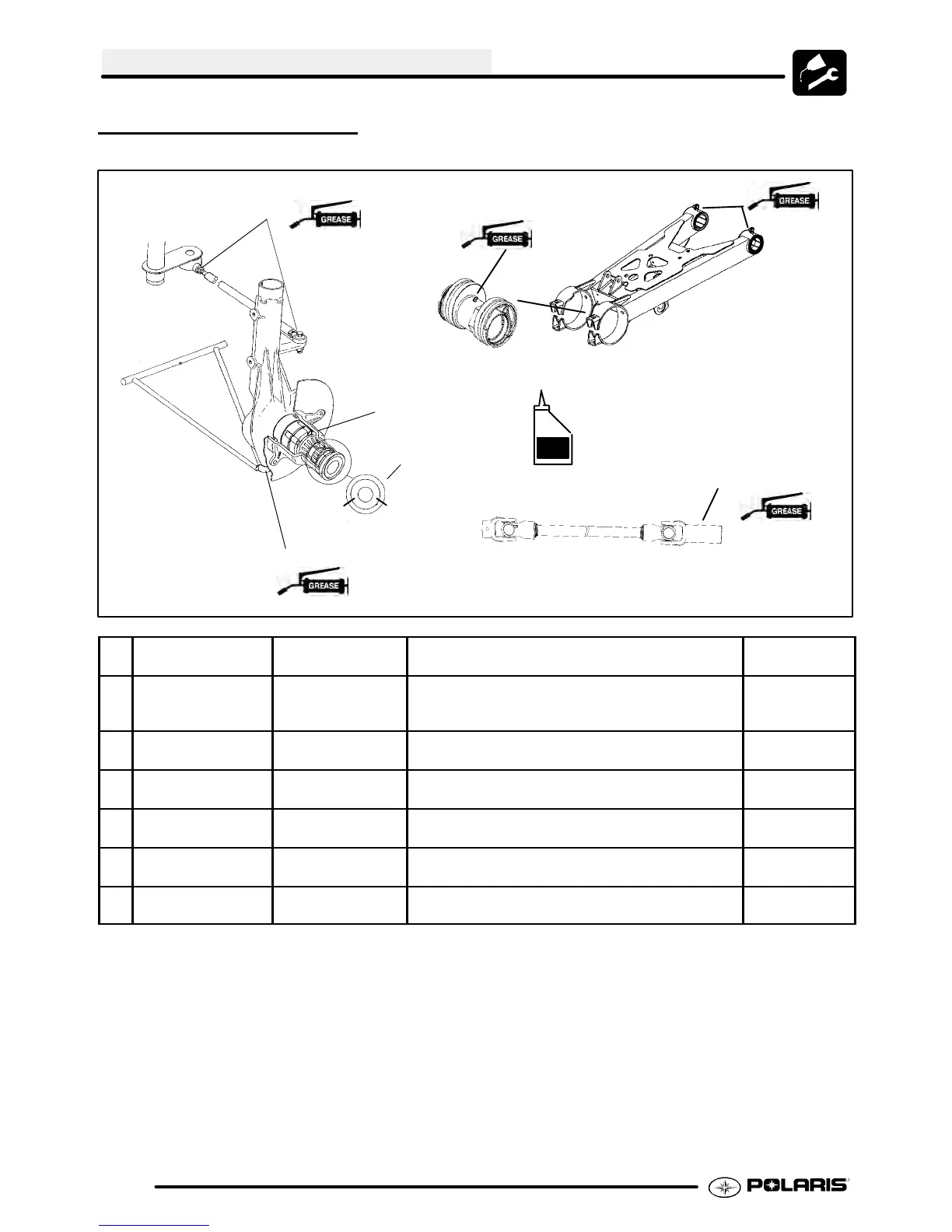

7. Tie Rod End

6. Ball Joint

5. AWD Hubs

4 or 8 O’clock position-

(end view)

8. Propshaft Yoke

(3 pumps max.)

10. Rear Concentric Housing

9. Swing Arm Bushings

DHF

Ill.

#

Item Lube Rec. Method Frequency*

5 All Wheel Drive

Hubs -- ATVs

Polaris Demand

Drive Hub Fluid

Remove filler hole screw in hubs. Rotate wheels to

4 or 8 O’clock position. If lubricant is not visible add

until it flows from filler hole. Reinstall screw.

Semi-annually

¡

6 Ball Joint Polaris All Season

Grease¢

Locate grease fitting on back side of struts and

grease with grease gun.

Semi-annually

¡

7 Tie Rod Ends Polaris All Season

Grease¢

Lift boot. Clean away dirt and grease. Apply fresh

grease by hand and reassemble.

Semi-annually

¡

8 Propshaft Yoke Premium U-Joint

Grease

Locate fittings and grease - 3 pumps maximum Annually©

9 Swing Arm Bush-

ings

Polaris All Season

Grease¢

Locate grease fitting on swing arm and grease with

grease gun.

Semi-annually

¡

10 Eccentric Housing Polaris All Season

Grease¢

Locate grease fitting on eccentric housing and

grease with grease gun.

Annually©

* More often under severe use, such as operated in water or under severe loads.

¡ Semi-annually or 50 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

© Annually or 100 hours of operation (refer to Maintenance Schedule for additional information)

More often under severe conditions (operating in water or hauling heavy loads)

¢ Grease conforming to NLGI No. 2, such as Polaris Premium All Season Grease, Conoco Superlube M or

Mobilegrease Special

Loading...

Loading...