ENGINE

3.32

5. Measure the ID of the bushing in the recoil

housing (A) and in the crankcase and record.

Measure in two directions 90° apart to determine

if bushing is out of round. Calculate bushing

clearance. Replacebushingif clearanceexceeds

the service limit.

6. Inspect gear teeth on starter drive. Replace

starter drive if gear teeth are cracked, worn, or

broken.

FLYWHEEL/STATOR

REMOV

AL/INSPECTION

1. Remove flywheel nut and washer.

2. Install FlywheelPuller (PN 2871043) andremove

flywheel. CAUTION: Do not thread the puller

bolts into the flywheel more than 1/4″ or stator

coils may be damaged.

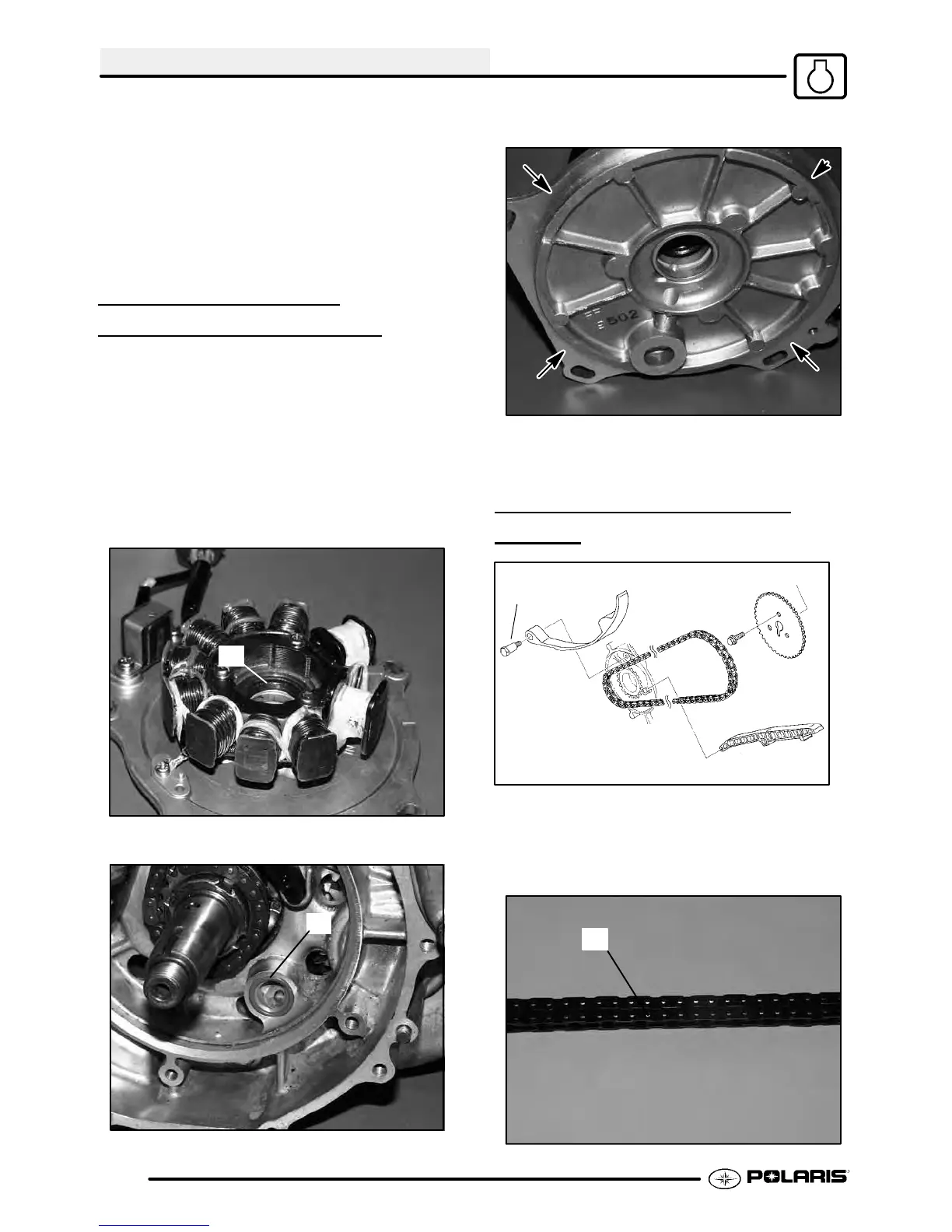

3. Markornotepositionofstatorplateoncrankcase.

4. Remove bolts and carefully remove stator

assembly,beingcarefulnottodamagecrankshaft

bushing on stator plate.

A

5. Replace crankshaft seal (A).

B

6. Remove oil passage O-Ring (B).

7. Remove large sealing O-Ring from outer edge of

stator plate.

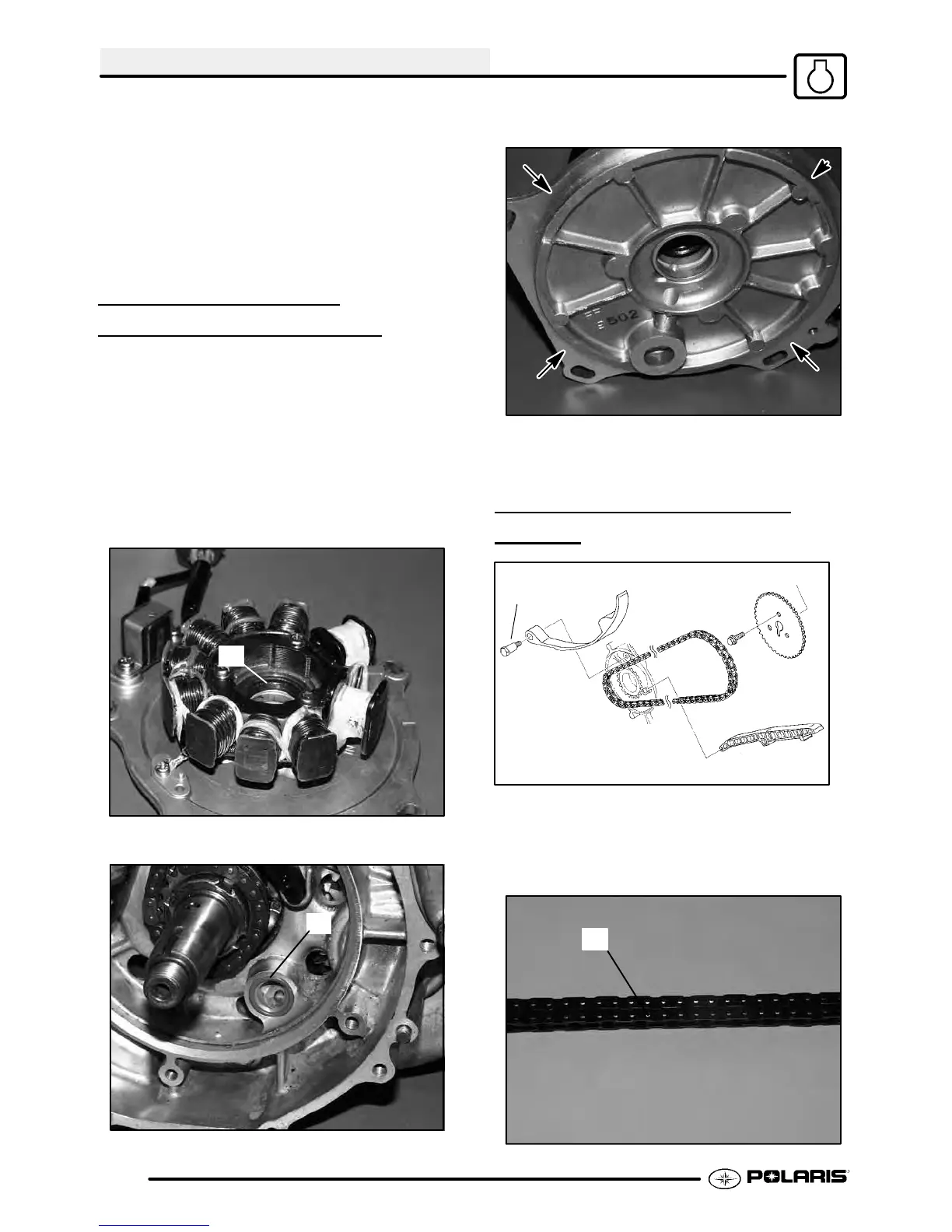

CAM CHAIN/TENSIONER

BLADE

A

1. Remove bolt securing tensioner blade to

crankcase (A).

2. Remove blade and inspect for cracks, wear, or

damage.

B

Loading...

Loading...