141

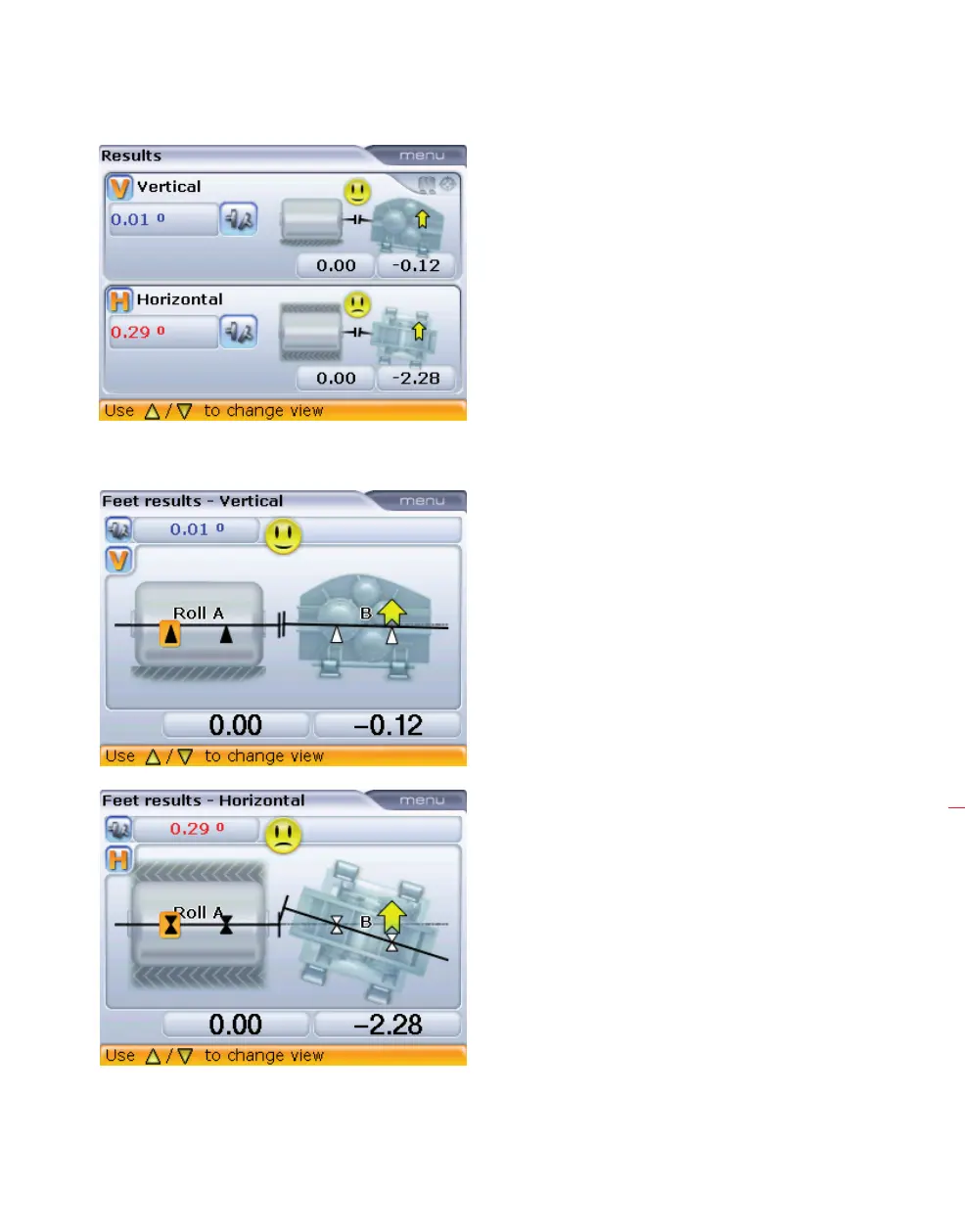

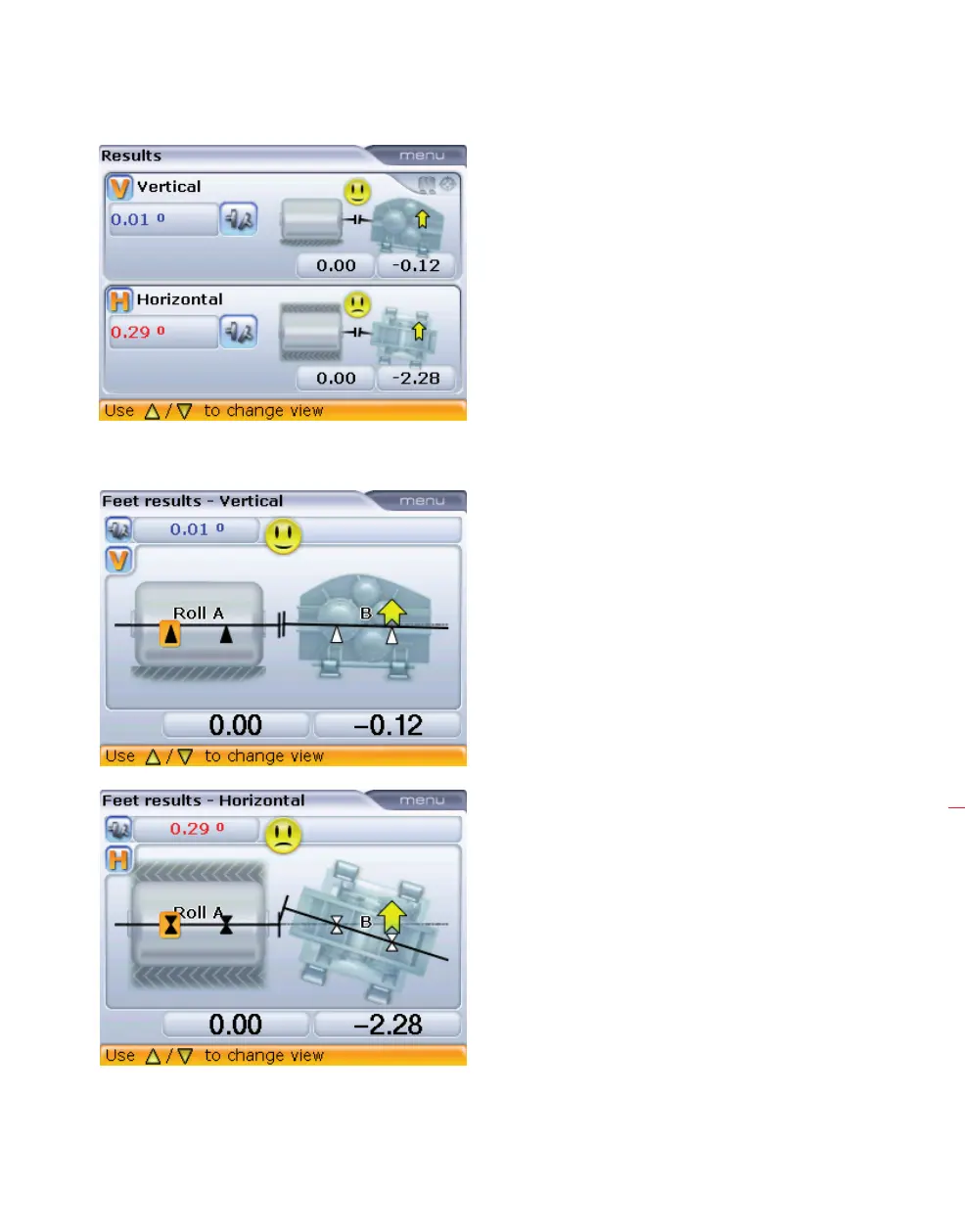

2. Cycle through the feet results using k/f/g.

3. If the machines are out of tolerance, reposition them with the help of the Move

function (refer to sections 5.13.3 – 5.13.5).

4. Remeasure to determine the new alignment condition.

Note that the angularity

is displayed in degrees

or mrad depending on

the ‘Angle format units’

selected under ‘Shaft

settings’ in the ‘Con-

figuration’ menu (refer to

section 8.2.7).

If a specific amount

of offset between the

machine shafts was

desired and the laser

holder assembly was set

up to this precise offset

as described in step 2

(section 7.2.2) previously,

then, after the angular

alignment of the movable

machine is completed,

remount and readjust

the laser as described in

steps 1–5 (section 7.2.3)

and proceed to adjust

the movable machine in

a parallel manner both

vertically and horizontally

until the beam spot hits

the movable machine

shaft‘s centerline of

rotation, taking care not

to change its angular

alignment.

Cardan drive machines

Loading...

Loading...