Quick check

99

5.15 Quick check measurement

At some point, it may be necessary to check the alignment of a machine set that

has been running long enough to reach its ‘steady state’ (‘hot’) operating condition.

In that case, the system can be used to take quick alignment readings in a matter

of a few minutes after the machines are shut off. The following procedure saves

time by allowing the user to begin measurement immediately after switching on the

computer and not entering machine dimensions first.

1. As soon as the shafts have stopped rotating, lock out machines and observe

all safety precautions, then mount the components as described on section 5.4

[‘Mount laser and RS5 BT sensor’].

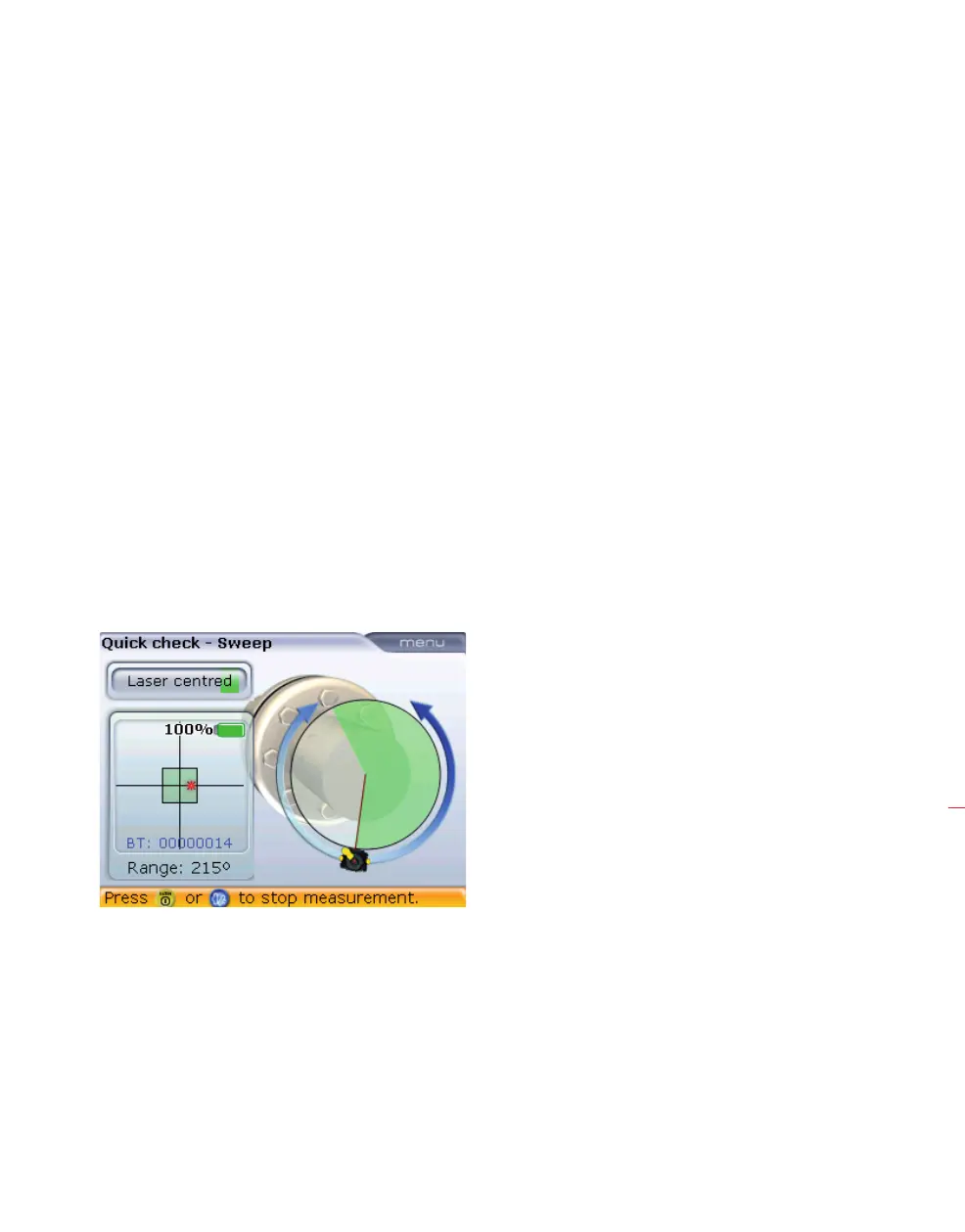

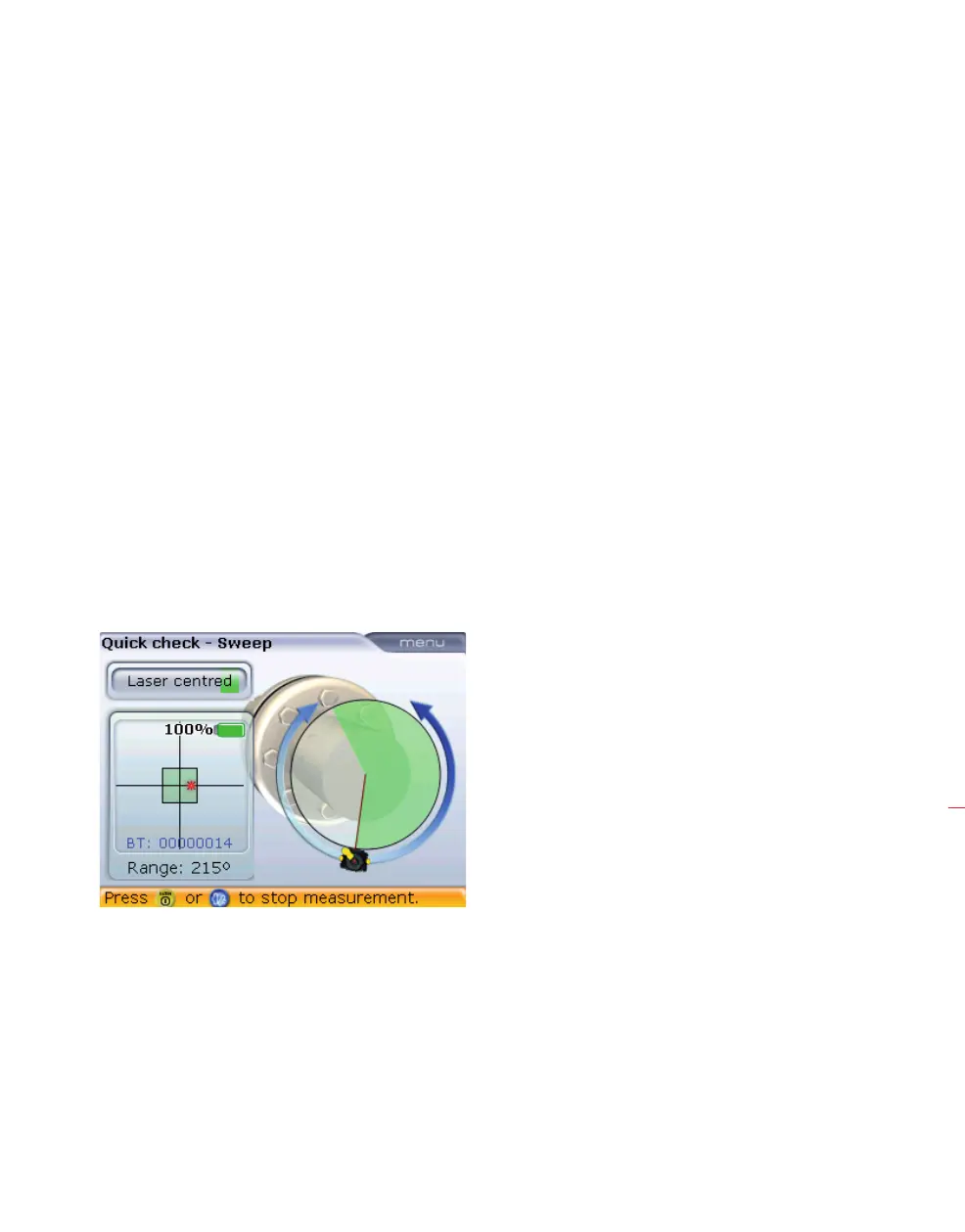

2. Switch both the OPTALIGN smart computer and the RS5 BT sensor on, then

press

m to establish wireless communication between the computer and the

sensor [for details refer to section 5.9.1]. If the laser beam has been centered

on the detector, turn the shafts in their normal direction of operation by at least

70°.

3. After rotating the shaft by at least 70°, press the results key

k. The

“Dimensions” screen with missing dimensions opens.

If however measurement

is finished by pressing

e, then pressing the

the results key

k to

view foot results, a hint

screen appears requesting

missing dimensions to be

entered.

Loading...

Loading...