Operating Manual Page 52 / 116 Copyright © REA Elektronik

REA ScanCheck 3n

V 1.2.0 24/02/2020

Other measured data and threshold values always shown in the reference test report in the

context must be ignored for this test.

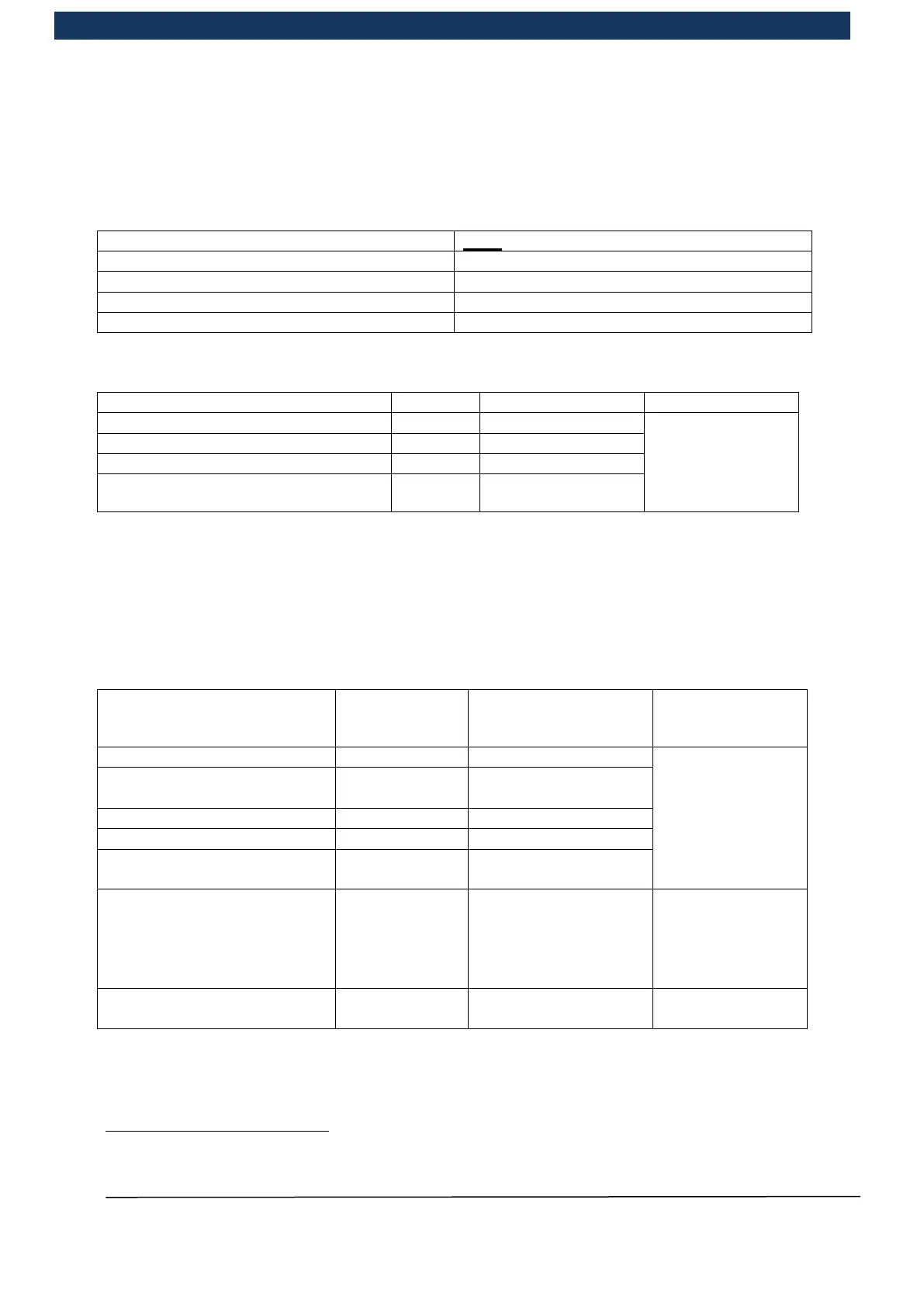

Measuring tolerances for apertures from 6 to 10mil

The following table lists the criteria to be verified in accordance with ISO/IEC 15426-1.

Measurement

values on the

stamped

reference test

report

*In standard ISO/IEC 15426-1 the values for defects and decodability are cited as absolute values

with reliable tolerances of +/-0.08. For improved comprehensibility, we refer to these two values on

the test reports as percentages. The corresponding tolerance values are therefore +/- 8. In the

event that the tolerances for decodability and/or defects are exceeded, the device must be

inspected and serviced at the manufacturer.

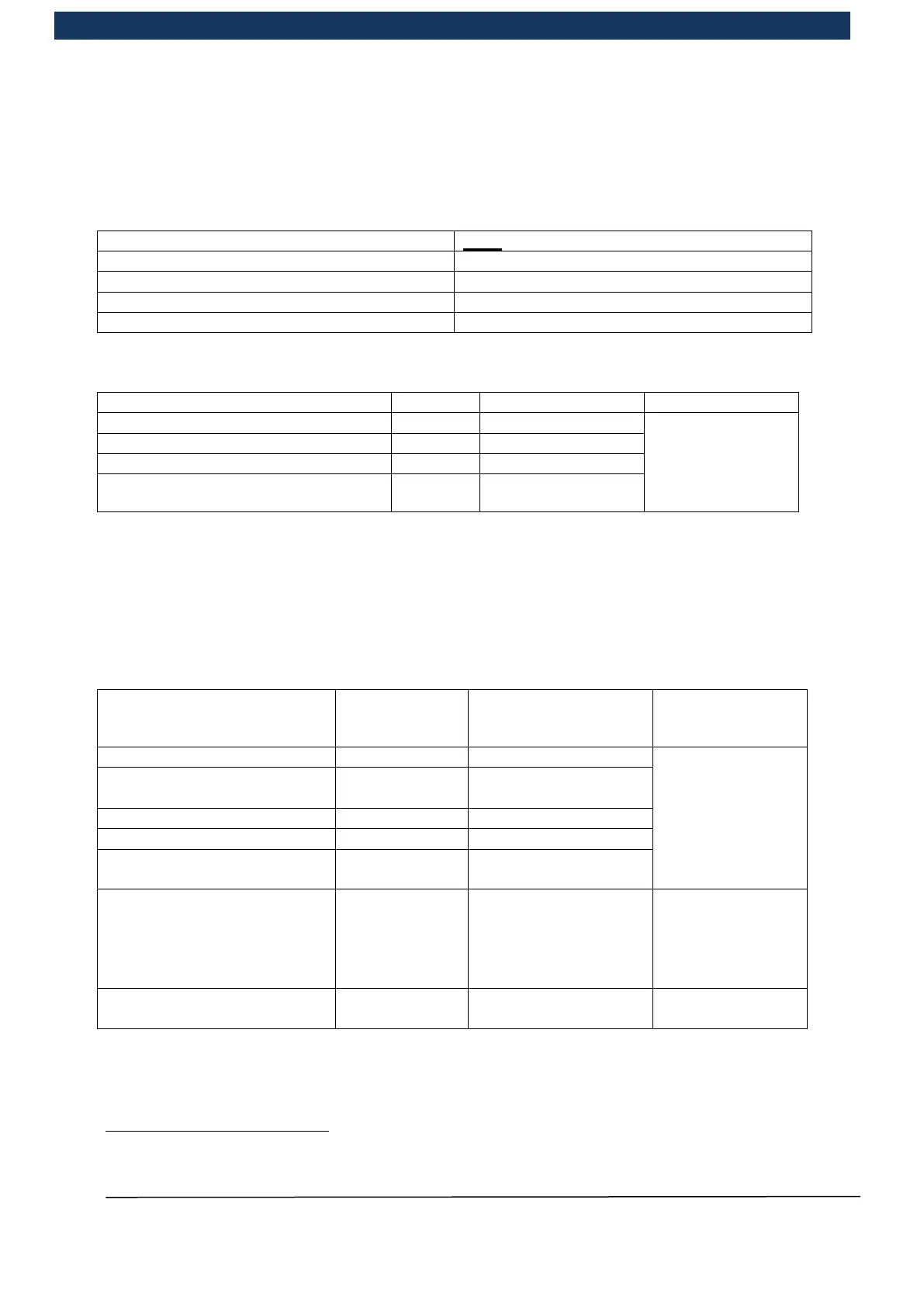

Other test criteria

Measurement

values on the

stamped

reference test

report

Average bar variance

(shown as mean)

Maximum bar variance

(shown as bar, two values

must be checked)

Tolerance refers

to the mean

value on the

reference test

report

The terms “calibration” and “adjustment” are used in accordance with the definition of DIN 1319-1

and JCGM 200.

Aperture – the light point size in accordance with the definition of ISO/IEC 15416

Rmax – the maximum reflection in the symbol determined in accordance with ISO/IEC 15416

Rmin – the minimum reflection determined in accordance with ISO/IEC 15416

Loading...

Loading...