Operating Manual Page 55 / 116 Copyright © REA Elektronik

REA ScanCheck 3n

V 1.2.0 24/02/2020

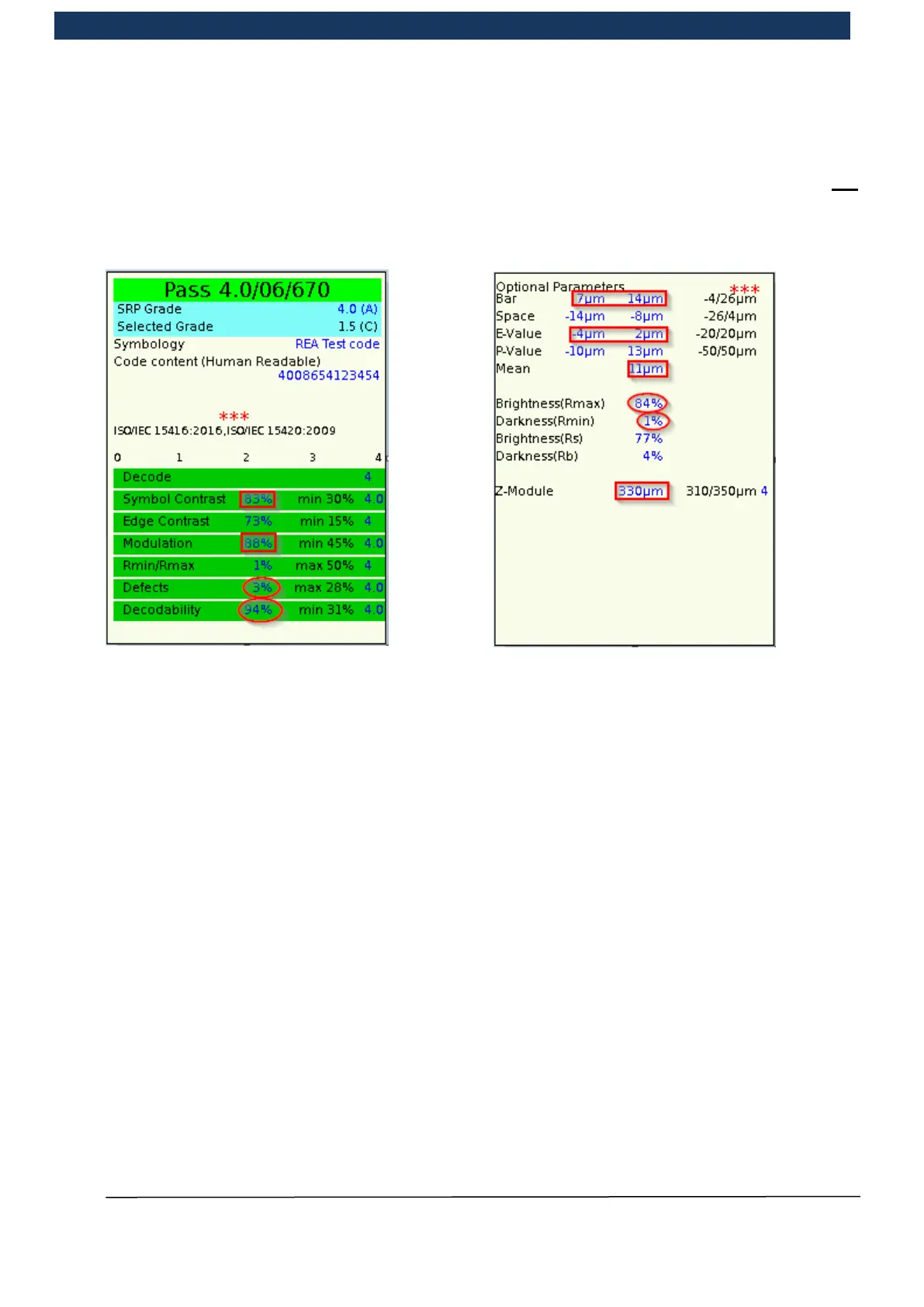

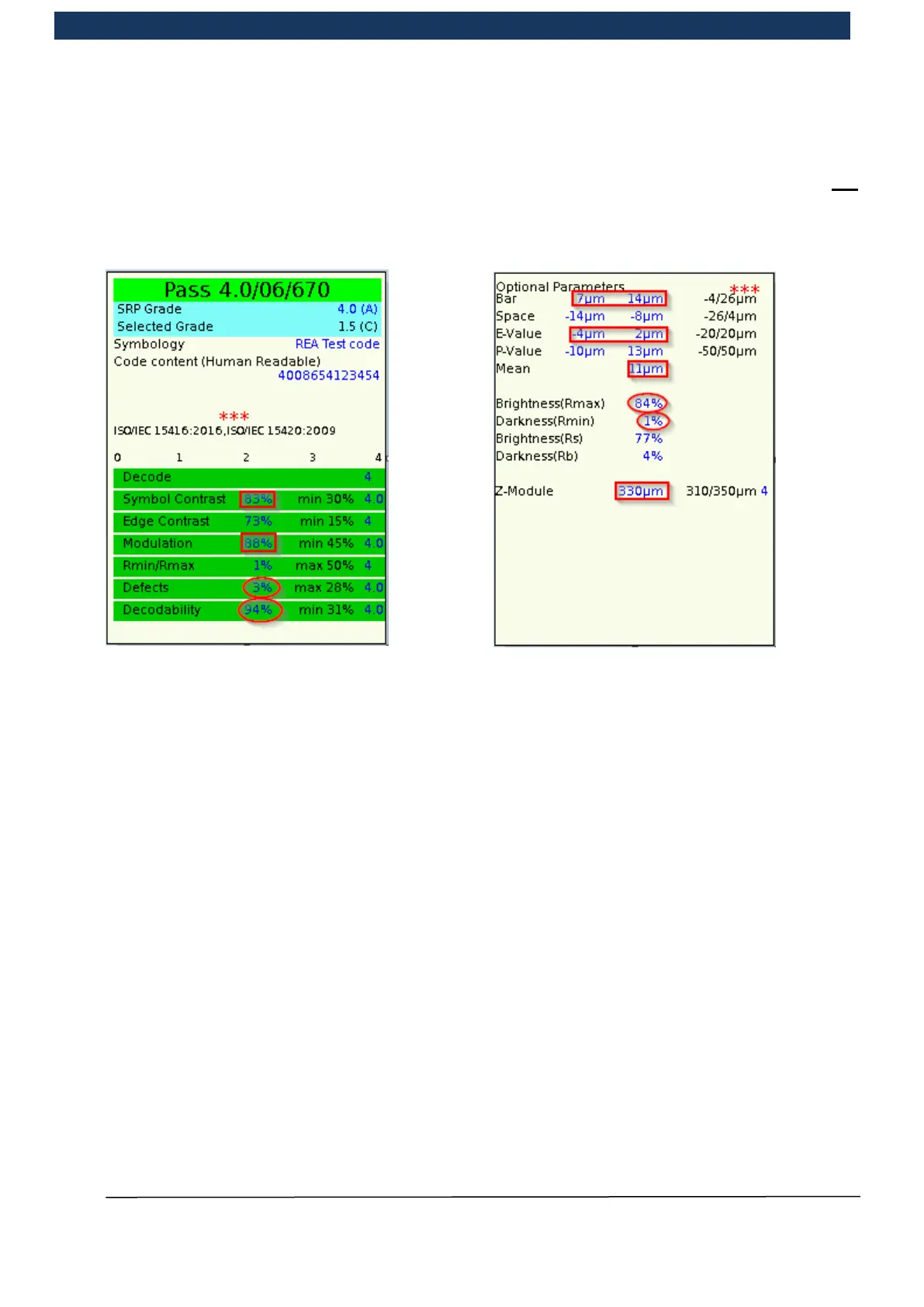

The values marked in red are the reference values that must be tested in accordance with the

standard ISO/IEC 15426-2. The values marked in blue are additional specifications of the

manufacturer, which exceed the minimum requirement of the standard. All other information is not

relevant for the calibration.

The ScanCheck 3 display shows the values to be compared on the first and fifth display screen

The circled values are ISO/IEC 15426-1 values, which are compared with the values of the

reference test report with consideration of the permissible tolerances.

The square-framed values are expanded control values in accordance with the manufacturer’s

specifications, which exceed the minimum requirement of the standard. These values must concur

with the values of the reference test report, within the framework of the permissible tolerances.

5 Operating the REA ScanCheck 3n

This chapter describes the operation and handling of the REA ScanCheck 3n. All operating steps

for the TransWin32 analysis software are explained in the TransWin32 operating manual; they will

not be repeated in this operating manual. It must be kept in mind that the REA ScanCheck 3n has

the task of measuring bar codes. The measurement results must be repeatable and comparable

with one another. This requires that all measurements are conducted at consistent conditions.

Essentially, the angle and distance of the REA ScanCheck 3n to the test specimen, the measuring

aperture and the wavelength of the light source must always remain the same.

As described in Chapter 1 “Introduction to REA ScanCheck 3n”, the REA ScanCheck 3n is an

optical measuring device. The characteristics and differences compared to a reading device

(scanner) mentioned there must be taken into consideration. With the test results, the REA

ScanCheck 3n provides evidence of quality problems. In actual practice, such quality problems can

result in non-significant restrictions in the reading rates up to total failure. As a form of quality

assurance, the verification allows the elimination of a problem before failures in the application crop

up.

Loading...

Loading...