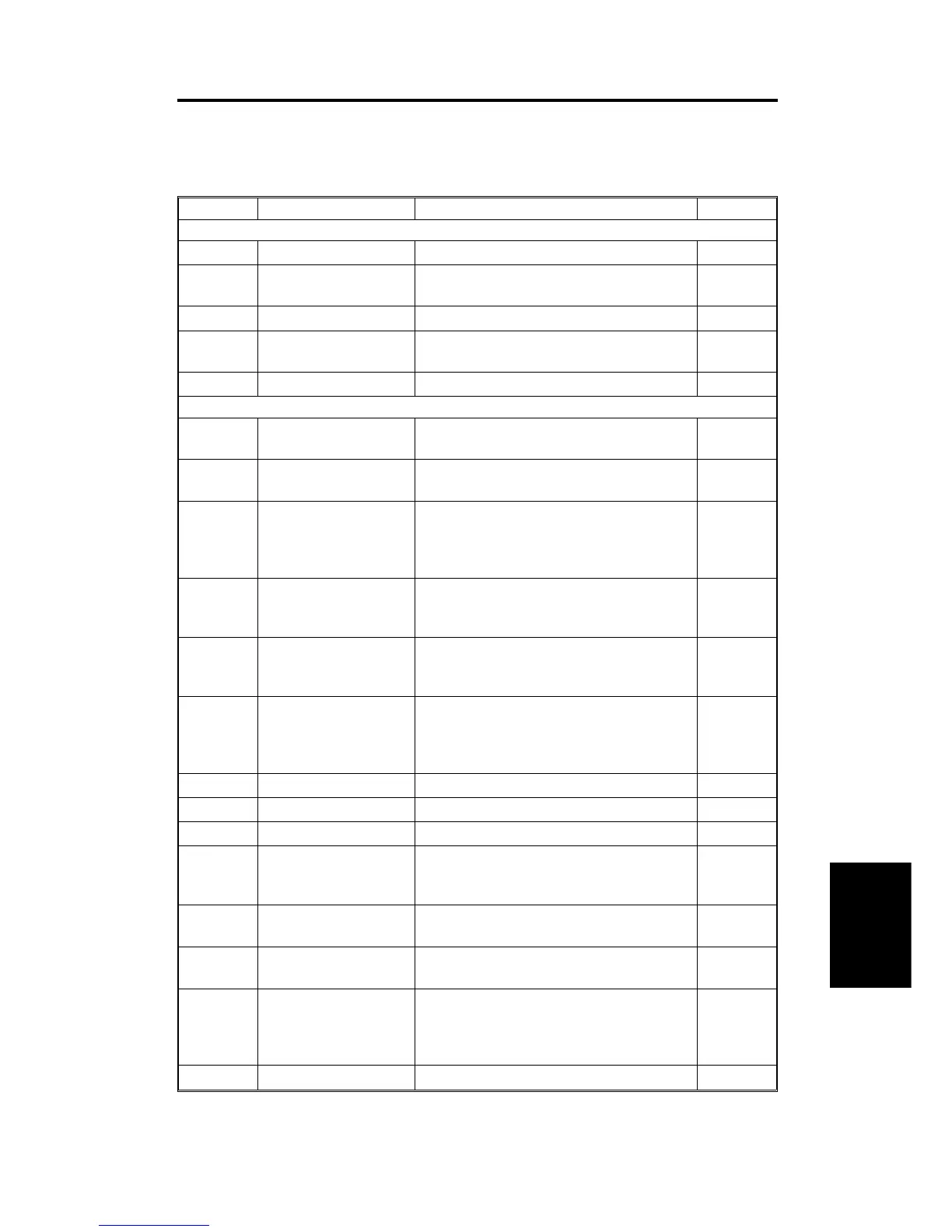

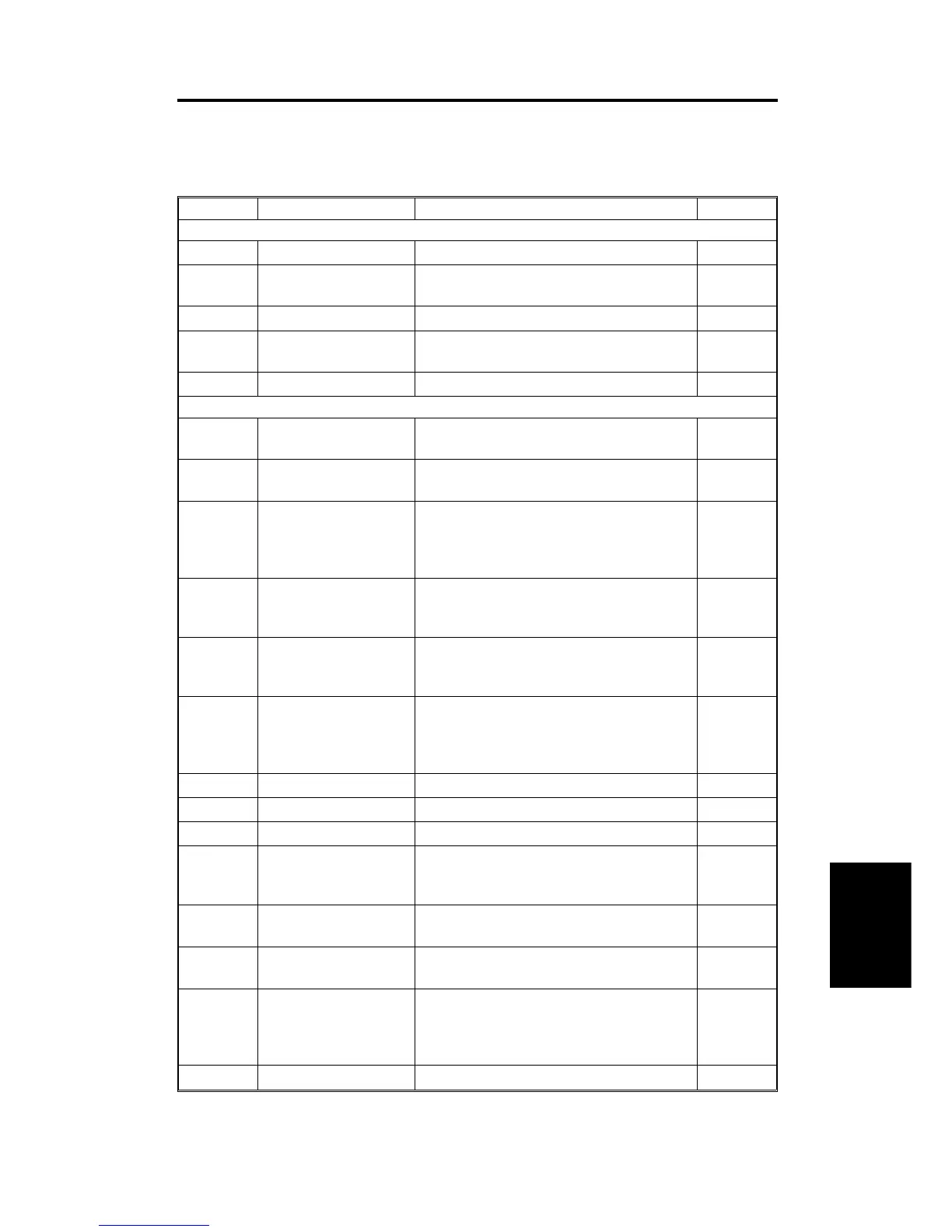

3. ELECTRICAL COMPONENT DESCRIPTION

Refer to the electrical component layout on the reverse side of the

point-to-point large size diagram for symbols and index numbers.

Symbol Name Function Index No.

Motors

M1

Friction Belt Drives the friction belt.

2

M2

Feed-in Drives the feed-in system (pick-up, feed,

pull-out rollers)

3

M3

Belt Drive Drives the transport belt.

5

M4

Feed-out Drives the feed-out and the inverter

system.

10

Sensors

S1

Feed-in Cover Open Detects whether or not the feed-in cover is

open.

1

S2

DF Position Informs the CPU whether the DJF is in the

up or down position.

7

S3

APS Start Informs the CPU when the DJF is being

closed so that the original size sensors in

the main body can check the original size

(in platen mode).

8

S4

Feed-out Checks for original misfeeds and sets

original stop timing when in auto-reverse

mode.

11

S5

Pulse Count Counts the pulses generated by the pulse

generator disc to determine the original

length.

12

S6

Registration-2 Detects the leading edge of the original to

turn off the feed-in clutch and to change

the feed-in motor speed. Also detects the

original length.

13

S7

Original Width-1 Detects the original width.

14

S8

Original Width-2 Detects the original width.

15

S9

Original Width-3 Detects the original width.

16

S10

Registration-1 Detects the original length and original

jam by detecting the trailing edge of the

original.

17

S11

Original Set Detects if originals have been placed on

the feed table.

18

S12

Original Feed Detects if the originals have reached the

feed roller or not.

19

S13

Friction Belt Turn Counts the pulses generated by the pulse

generator disk to monitor the friction belt

motor.

20

Dual Job Feeder

DF62 (A610)

SM 7-5 A172/A199

Loading...

Loading...