PAPER FEED SECTION (MAIN BODY) 1 March, 2000

6-18

6.3 PAPER FEED SECTION (MAIN BODY)

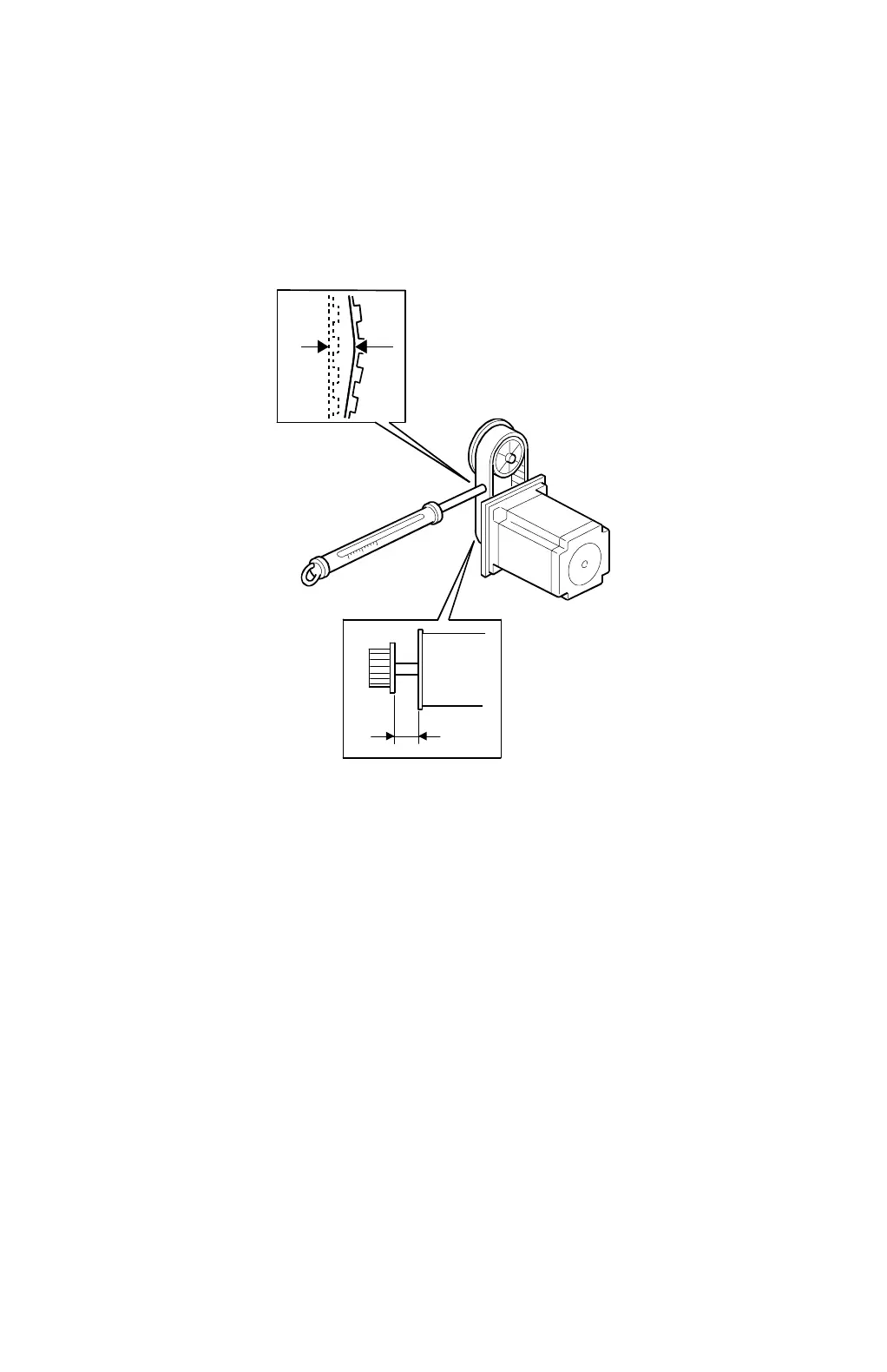

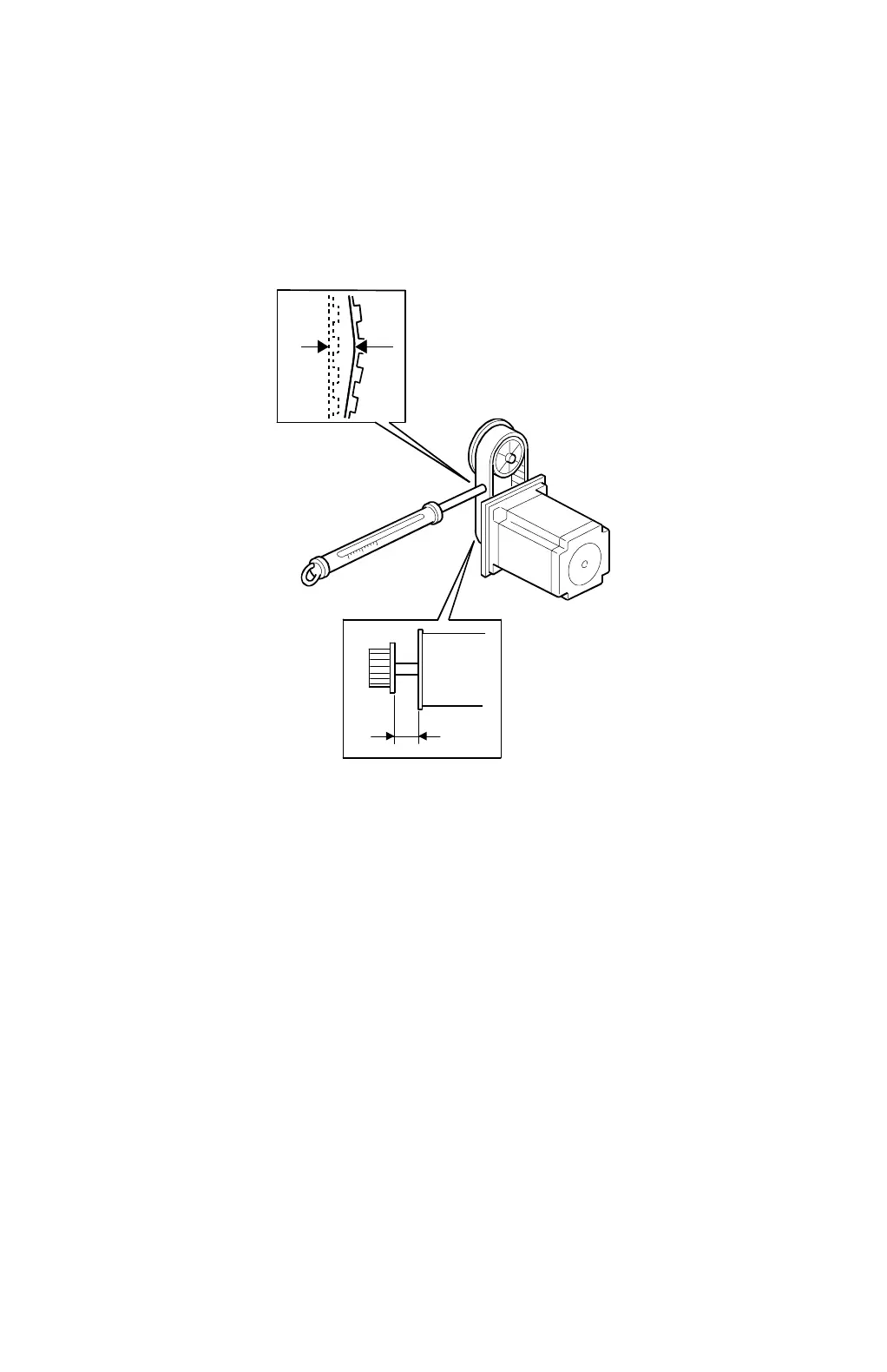

6.3.1 TIMING BELT TENSION ADJUSTMENT FOR THE

REGISTRATION MOTOR

1. Make sure that the distance between the motor and the flange is 8 ± 0.5 mm.

2. Apply a 500g load to the center of the belt using a tension gauge. Make sure

that the belt deflects between 2 to 4 mm. If the tension is incorrect, move the

motor up or down.

C232R014.WMF

2 ~ 4 mm

8 ± 0.5 mm

Loading...

Loading...