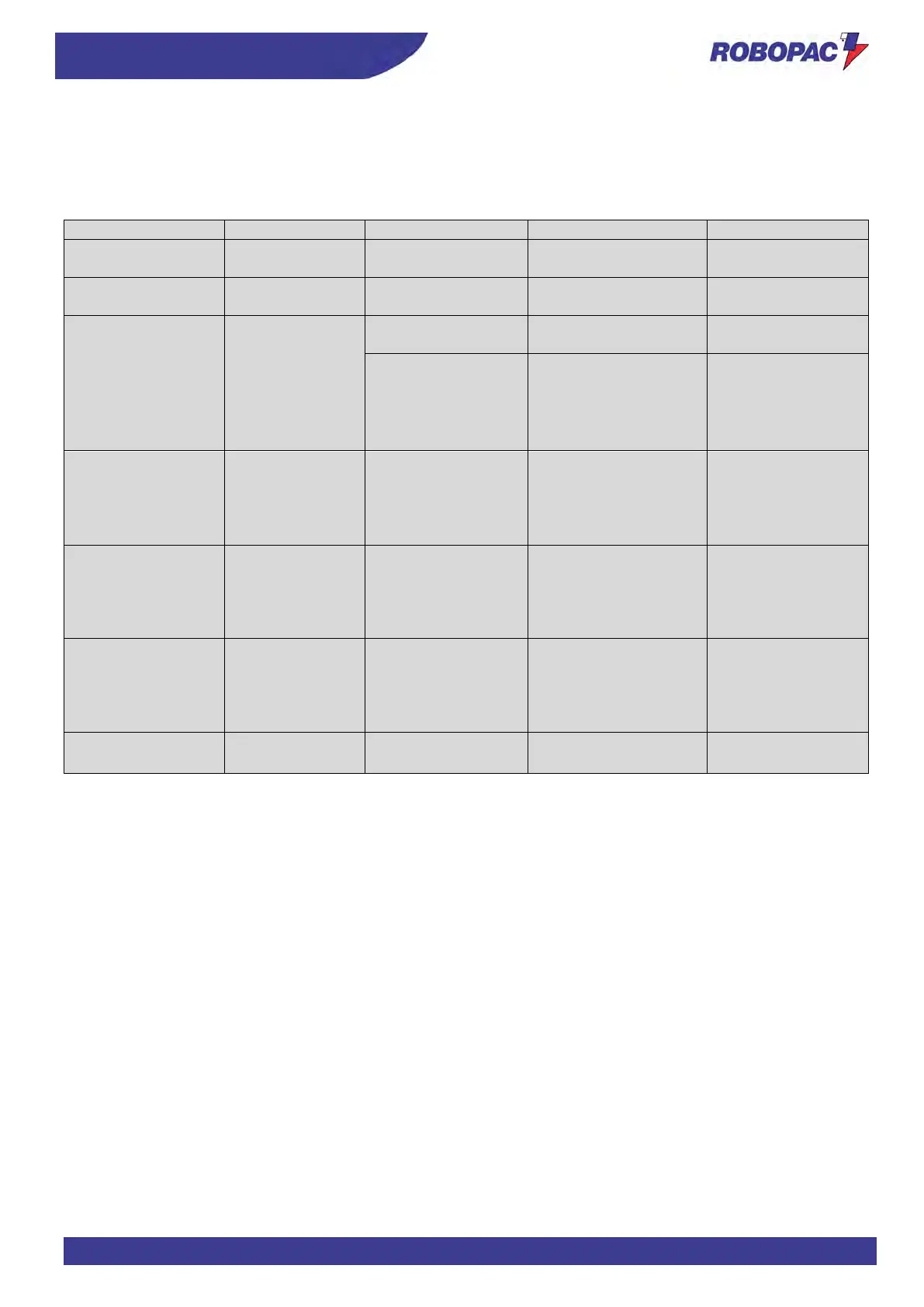

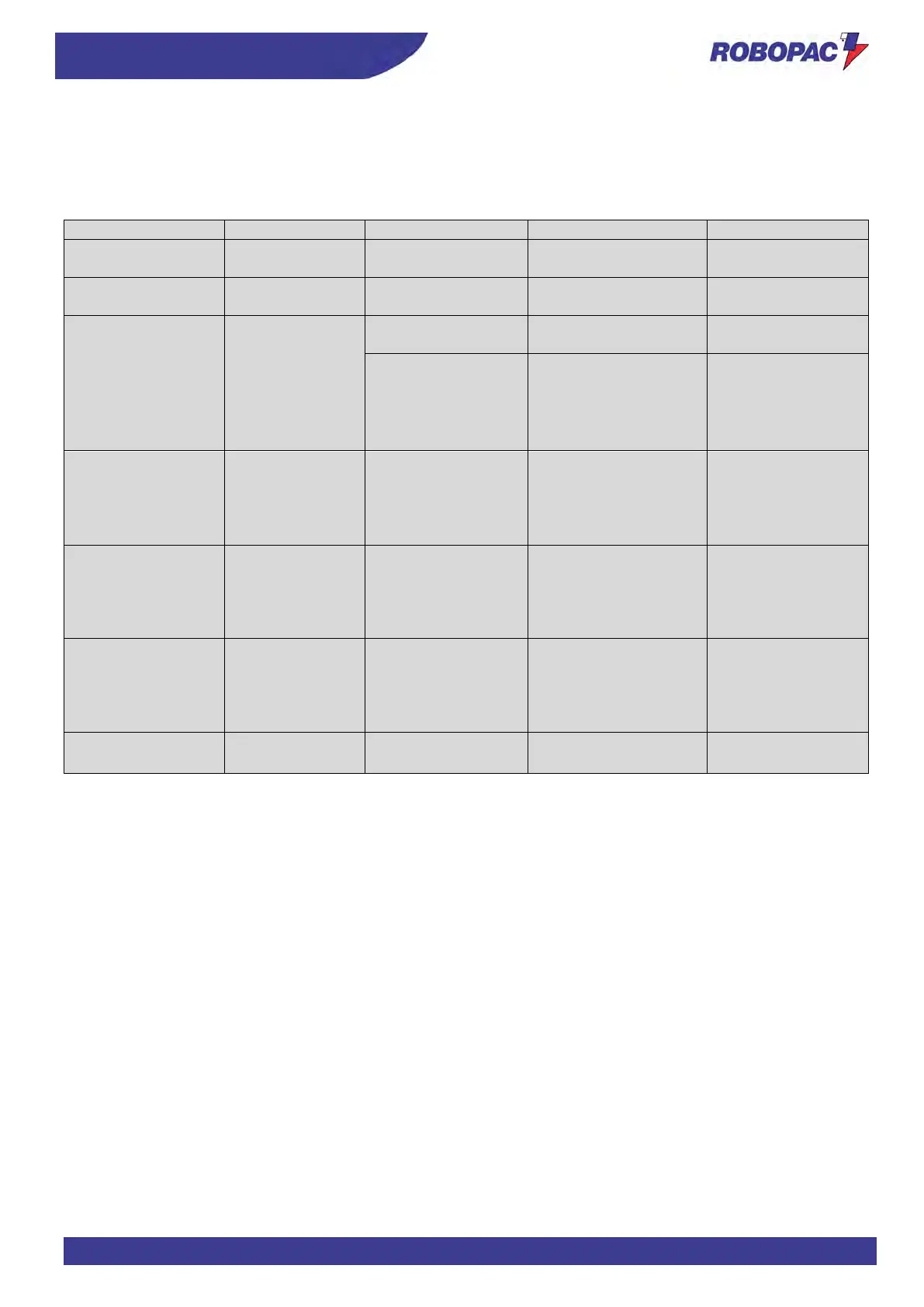

7.2. PERIODICAL MAINTENANCE INTERVALS

The table indicates the scheduled maintenance intervals which allow to obtain best performance, long operating life and

a constant level of safety.

Maintenance interval table

Every 40 hours or

1000 cycles (*).

Every 200 hours or

5000 cycles (*).

Use a cloth soaked in

alcohol

5000 cycles (*)

See “Lubrication

point diagram”

tensioning

lifting chain

adjustment”

5000 cycles (*)

fastening elements

are screwed at the

correct tightening

to check tightening

torques

5000 cycles (*)

fastening elements

are screwed at the

correct tightening

to check tightening

torques

5000 cycles (*)

fastening elements

are screwed at the

correct tightening

to check tightening

torques

Every 5000 hours

or 50000 cycles (*).

Reduction units

and gearmotors

See “Lubrication

point diagram”

1

Do not top up and/or change in life-lubed reduction units and gearmotors.

∗ Cycle timings have been defined on the basis of the standard cycle.

The standard cycle is the following: 500 mm high film spool, 1500 mm high pallet, pallet weight equal to 1500

kg, total wrapping cycle consisting of two turns at the base, two turns at the top with rotation speed of 12 r.p.m.

or

80 m/1’ and carriage upstroke and downstroke speed equal to 4 m/1’.

Loading...

Loading...