WARNING

Tip Over Hazard

l

The forksof the pallet truck or forklift truck must be at least 1,065 mm (42 in) in length.

l

The weight capacity of the pallet truck or forklift truck must be at least 250 kg (550 lb).

l

The Solution must be transported on a level, even and solid concrete surface using a pallet truck or

forklift truck.

l

The robot should be positioned asper the moving and positioning instructions.

l

The cabling and tubing must be disconnected before transportation.

l

The Solution should be lifted aslittle aspossible, and attention must be paid to the center of gravity

to reduce the risk of tip over.

l

It isthe responsibilityof the user to determine a safe and stable course of action for the moving of the

Solution using rigging and hoisting equipment.

l

Employeesshould be qualified and properlytrained on howto use the lifting/hoisting/rigging

equipment aswell asthe Solution

l

The Solution should be secured and stable prior to its moving and lifting

Failure to account for these factors may result in material damage, bodily injury or death.

Although the Solution can be assembled where needed, it may need to be moved to its final location afterwards.

Please follow the stepsbelow to safely move the Solution.

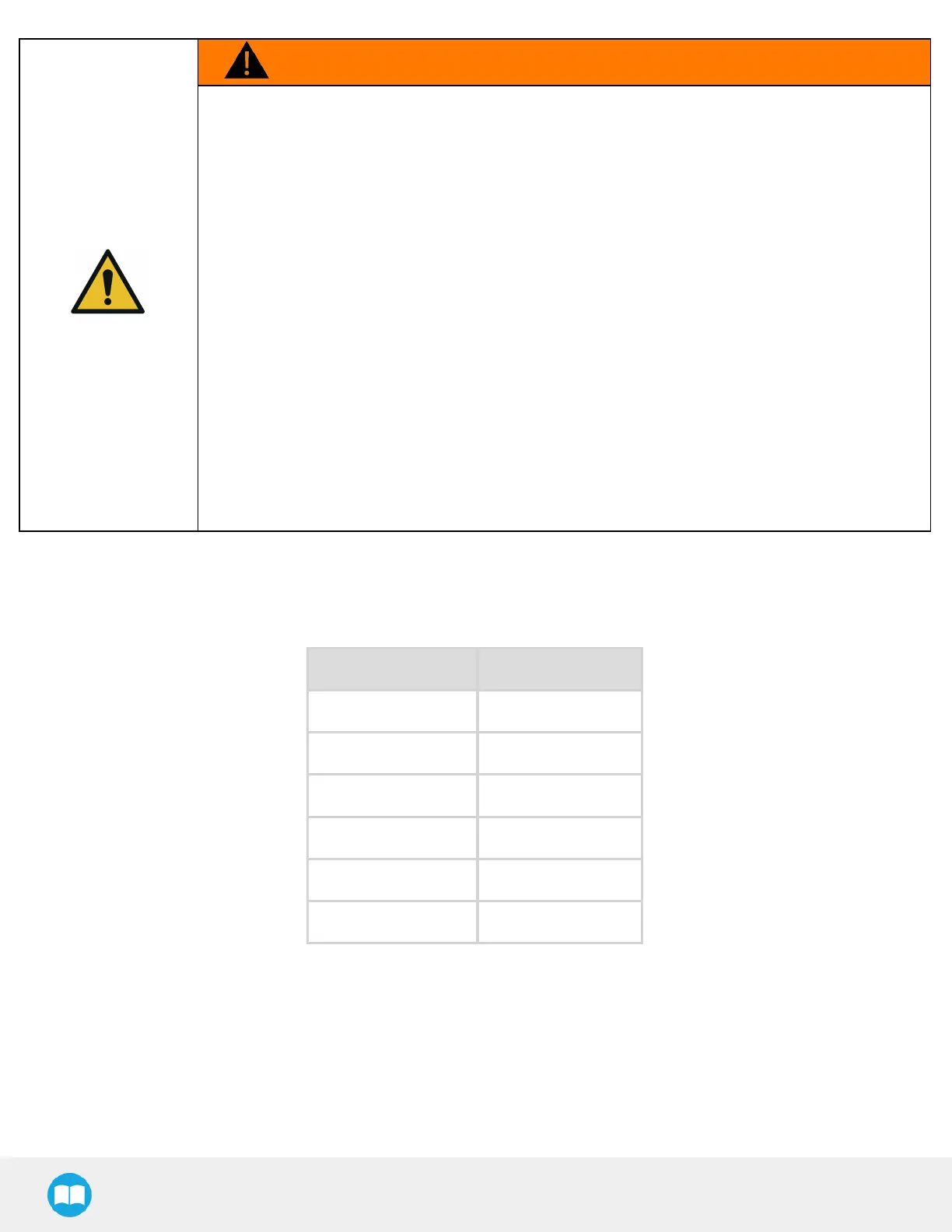

1. Set the robot in a transport position by referring to the joint positions below. Disregard thisstep if the robot hasnot been

installed yet.

Joint Position

Base -75°

Shoulder -200°

Elbow -125°

Wrist 1 90°

Wrist 2 90°

Wrist 3 90°

2. Disconnect the power and pneumatic supplies as well asany other cabling that may interfere with the movement of the

Solution.

3. Place the teach pendant on itsrack at the operator station, or place it on the support rack of the robot’s control box and run

the teach pendant cable on the base of the Solution.

53

Loading...

Loading...