Side overrun

Potential side overrun (mm) = (box diagonal/2) + robot reach + extra bracket reach - pallet width - 295

Trajectories are not limited to hovering over the picking position, the base of the Solution, and the pallets. It isthus important to

implement physical safeguarding devicesnext to the picking area, depending on the layout of the palletizing cell. The robot's

reachable area should be clearly identified and marked on the ground.

NOTICE

When the robot ispalletizing on one side, and no pallet ispresent on the opposite side, the Palletizing

Solution computes trajectoriesbased on the assumption that there are no obstacleson the opposite

side. The robot’s elbow (joint #2) can therefore extend to the side where no pallet is present. For a

UR20, tthe potential overrun is represented by a cylinder with a radiusof 1000 mm, with its axis aligned

with the Z-axis of the robot base.

Floormarking

Floor marking to delineate the working zone should be added.

3.5.OtherGrippers

It is possible to use a gripper other than the PowerPick Vacuum Gripper. If another gripper isused, it is important to validate that

its shape iswithin the gripper model used for the collision detection algorithm of the software. If the shape of the alternative

gripper does not correspond with the shape of the following models, it might function as well, but Robotiq doesnot guarantee

that there will be no collision.

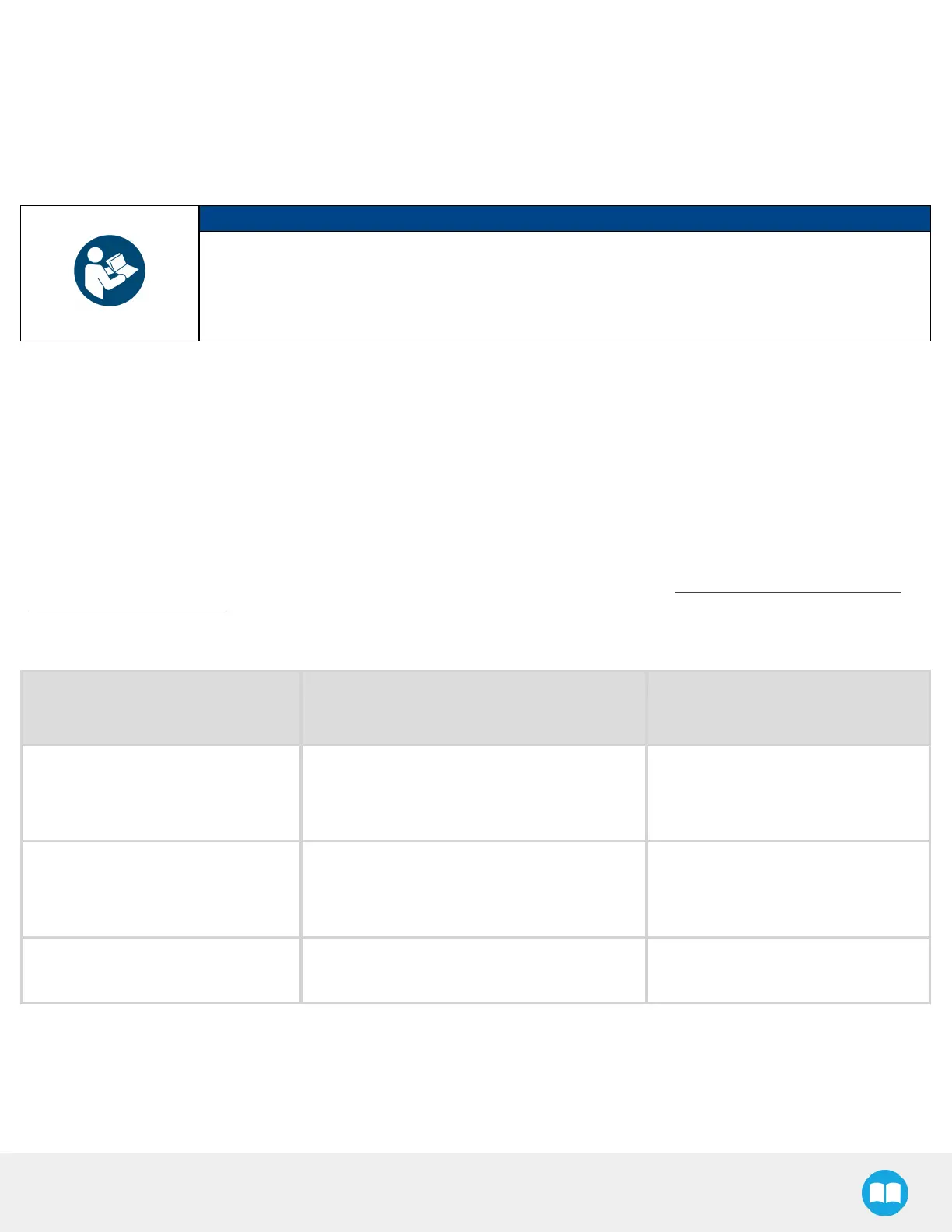

The dimensionsof the gripper model depends on the dimensions of the box to palletize and are obtained using the following

criteria:

BoxFootprint

(A

box

X B

box

)

Gripper Footprint

(A

g

X B

g

)

Gripper Height

(C

g

)

A

box

< 105 mm

OR

B

box

< 55 mm

A

g

= A

box

- 1 mm

B

g

= B

box

- 1 mm

110 mm

A

box

> 450 mm

OR

B

box

> 350 mm

A

g

= A

box

- 40 mm

B

g

= B

box

- 40 mm

55 mm

Otherwise

A

g

= 200 mm

B

g

= 130 mm

110 mm

58

Loading...

Loading...