106 Rockwell Automation Publication 750-RM004A-EN-P - April 2018

Chapter 2 Drive Configuration

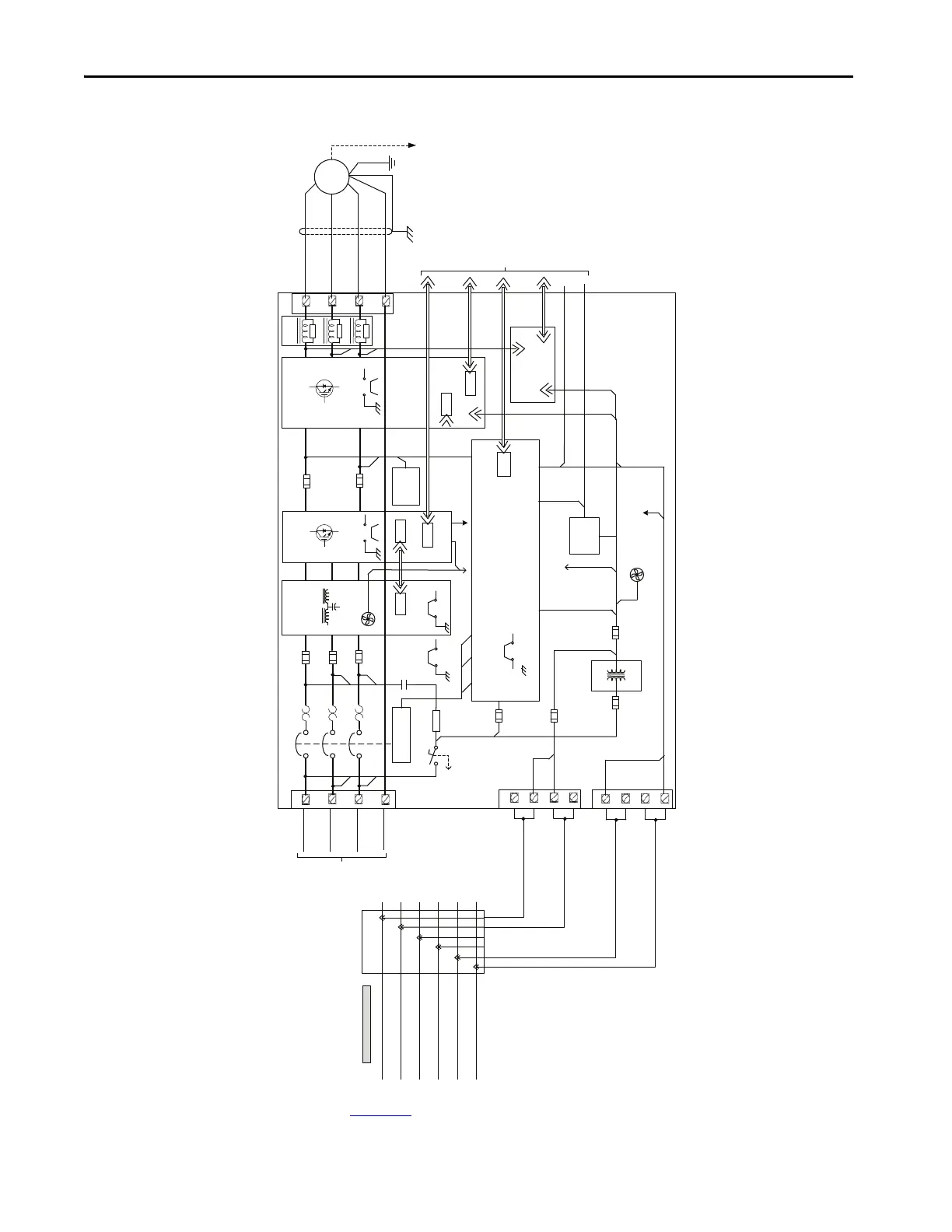

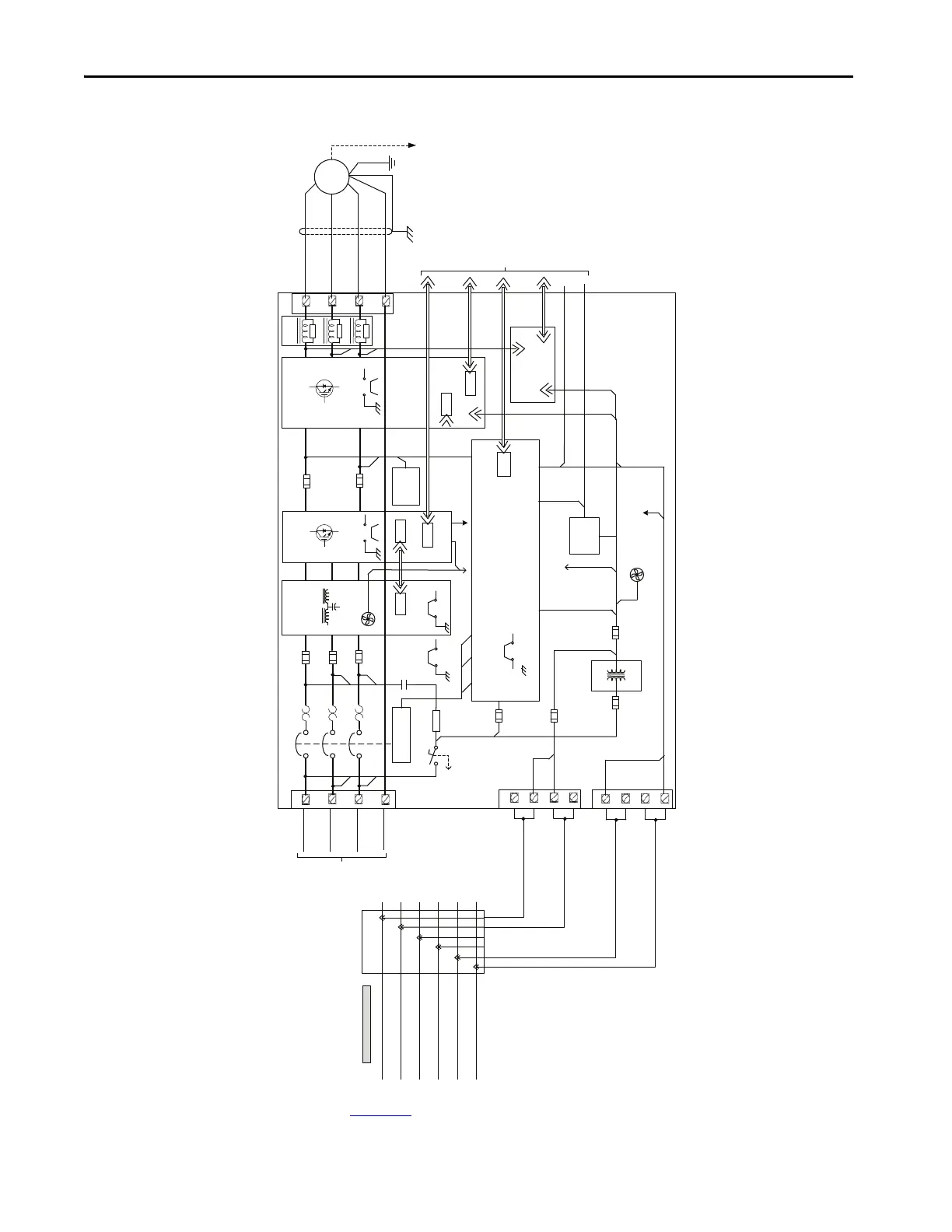

Figure 27 - PowerFlex 755TL Drive, Sample Frame 8 Wiring Diagram

Figure 27 shows optional equipment installed; Torque Accuracy Module

(TAM), and motor side inverter RWR output filter.

Control Bus

Connector 1

3Phase AC

Power Source

240VAC Line

240VAC Neutral

User 120/240VAC Line

User 120/240VAC Neutral

Aux 24VDC Pos

Aux 24VDC Neg

Control Bus Bars

To Control

Pod I/O and

Fiber Interface

Board

Fiber

Cable(s)

Fiber

Cable

L1

L2

L3

PE

Internal

Cooling

Fan(s)

F1...2

Line Side

Power

Structure

LCL Filter

M1

R1...3

Precharge

F3...5

CB1

FH3

240VAC

FH2

24VDC

P/S

PS1

24VDC

SYS

PE-A2

240VAC

CTRL

PWR

L2

L1

N1

N2

FH4

AC Pre-Charge

PCBA1

FD1

Motor Operator

Shunt Trip

FH1

LCL

CTL

PE-A

P8

PDI

AUX

24VDC

J12

SYS

24VDC

J1

J4

CB1-PRECHRG

240VAC

J5

J6

ACL

J7

DCB

J2

ACP

J3

TB2

TB5

+

+

-

-

T1

AUX

24VDC

AUX

24VDC

240VAC

P2

240vac/Aux24

J4

Door

Operator

240VAC to

LCL/PS

Aux 24VDC

to PS

DC +

DC -

Fiber

Cable

Motor Side

Power

Structure

J4

CTL

PDI

T1/U

T2/V

T3/W

PE

PE-A1

PE-B1

J6

J5

PE-B1

J6

J5

M

T1

T2

T3

G

TO ENCODER

AC

MOTOR

Bus

Conditioner

J3

J2

Torque

Accuracy

Module

J1

Fiber

Cable

RWR

Loading...

Loading...