R&S ZVL Measurement Examples

Advanced Tasks

Operating Manual 1303.6580.32-05

111

To prepare the distance-to-fault measurement, first perform a full one-port calibration at PORT 2:

Press the Preset key to restore standard analyzer settings, in particular a linear frequency sweep with

a relatively wide sweep range and a sufficiently large number of points.

Click Trace – Meas – Distance-to-Fault to switch on the distance-to-fault measurement, display the

distance scale and select S22 as measured quantity.

Click Trace – Meas – Distance-to-Fault – Full One-Port P2 Cal... to open the calibration wizard and

perform a full one-port calibration at the analyzer test port. Proceed in analogy to section

Manual_calibration, connecting the required Open, Short, and Match standards directly to PORT 2.

Click Cable Type to open the Cable Type dialog. In the list of cables, select your cable type (RG

141A). Press OK to close the dialog.

Adjust the Stop Distance to 3 m, according to the dimensions of your cables (approx. twice the total

length in order to view multiple reflections).

Observe the measurement result in the diagram area (see Analysis of Distance-to-Fault Results). If

desired, vary the diagram scale (Trace – Scale...).

If the second cable is of different type, you can still correctly locate the fault on the first cable using the

described settings. If your cable type is not in the list, you can easily add your own cable type with

arbitrary properties.

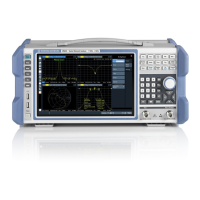

Analysis of Distance-to-Fault Results

The position of the spikes indicating faults and discontinuities is most easily monitored using markers

which are placed onto the peaks of the trace (Trace – Marker – Marker Search – Peak Search >). With a

matched termination at the end of the second cable, the following result is obtained:

The spikes can be interpreted as follows:

• Mkr 1 shows the position of the first adapter between the analyzer port and the first cable.

Loading...

Loading...