12 IQ3 manual – Section: Preparing the Drive Bush

5. Preparing the Drive Bush

5.1 IQ base all sizes types A and Z3

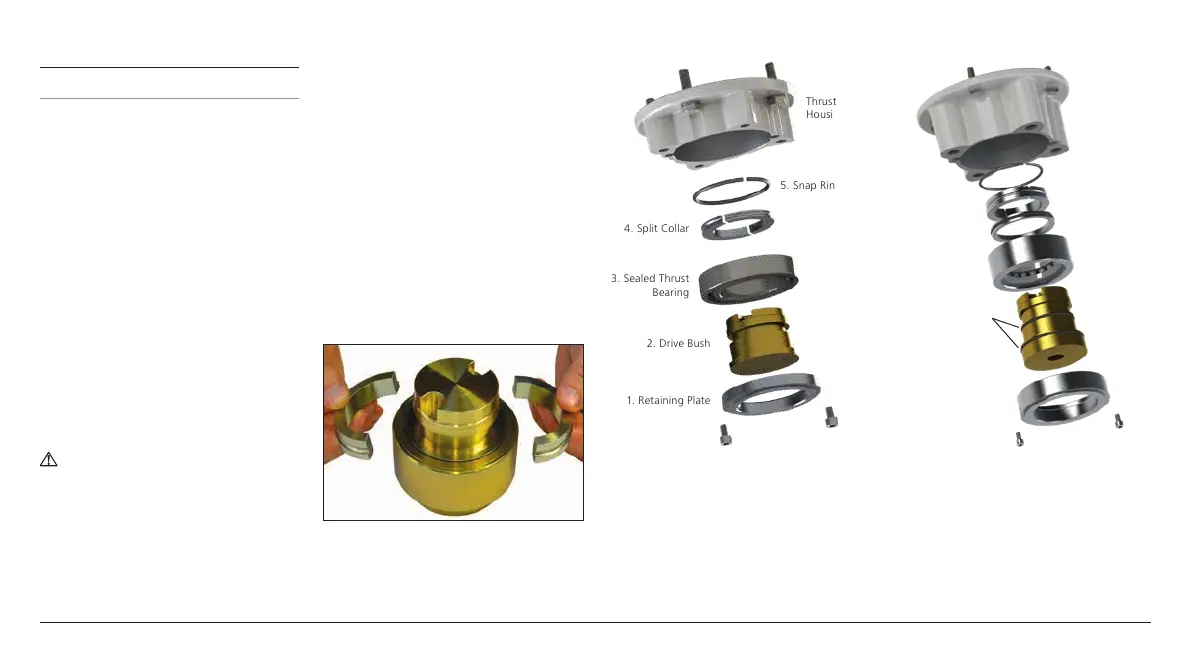

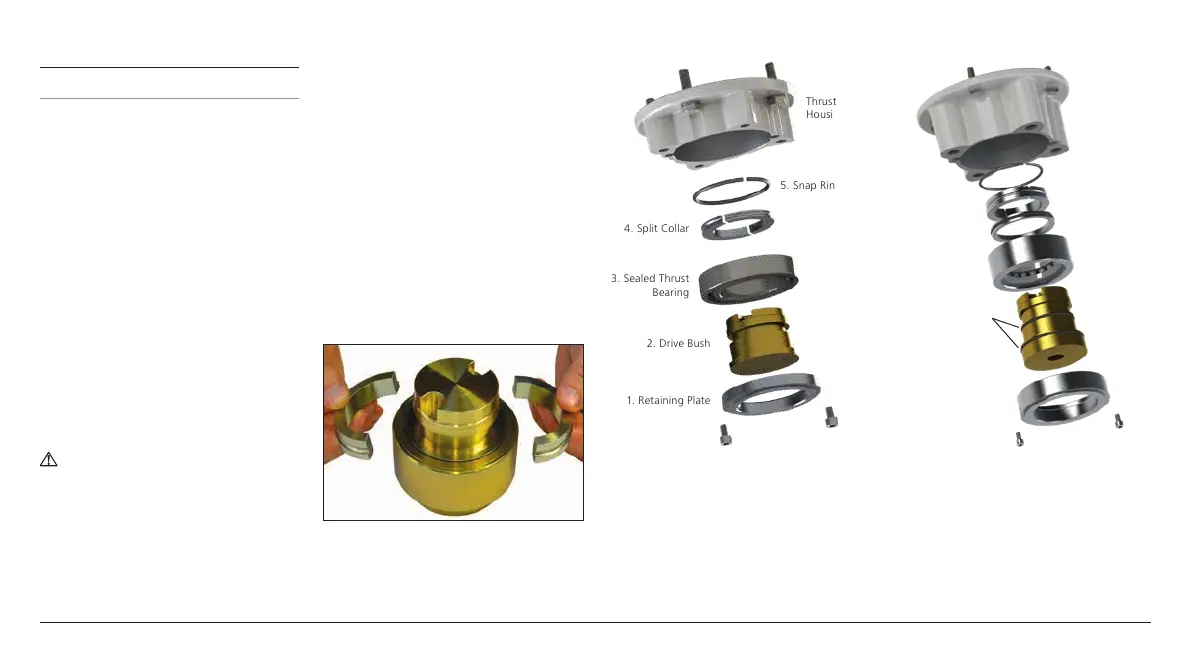

Turn actuator onto its side, remove the

cap-headed screws holding retaining

plate (1) onto the thrust base and pull

out the drive bush (2) complete with its

bearing assembly (3). Size IQ10 to 35

have 2 screws, size IQ40 to 95—F25

bases have 8 screws, and F30 have 10

screws. Before machining the drive bush

the thrust bearing must be removed.

IQ10 to 18 actuators have a sealed

thrust bearing located on the drive

bush and retained by the split collar (4)

and snap ring (5).

IQ20 to 95 have a thrust race bearing

within a steel bearing housing located

on the drive bush and retained by the

split collar (4) and snap ring (5). The

bearing is sealed within its housing by

O-rings located on the drive bush and

the bearing spacer ring (6).

WARNING: Failure to remove

the bearing assembly and O-rings

from the drive bush prior to

machining may result in damage

to the bearing.

Disassembly of bearing assembly

all sizes

Locate and remove the snap ring (5)

using a suitable tool. Remove the

split collar (4) See Fig. 5.1.1. Slide the

bearing (3) off the drive bush (2).

Note Additional spacer (6) and O-rings

to remove on sizes IQ20 to 95.

Keep the bearings and drive bush

locating components in a safe clean

place. The split collar (4) must be kept

as a matched pair.

Machine the drive bush (2) to suit

the valve stem, allowing a generous

clearance on the screw thread for rising

steam threads.

Fig. 5.1.1

1. Retaining Plate

2. Drive Bush

3. Sealed Thrust

Bearing

5. Snap Ring

4. Split Collar

Thrust Base

Housing

Fig. 5.1.2 F10 base assembly

1. Retaining Plate

2. Drive Bush

O-rings

3. Thrust Bearing

4. Split Collar

6. Bearing Spacer

Ring

5. Snap Ring

Thrust Base

Housing

Fig. 5.1.3 F14 & F16 base assembly

Loading...

Loading...