IQ3 manual – Section: Commissioning - Basic Settings 21

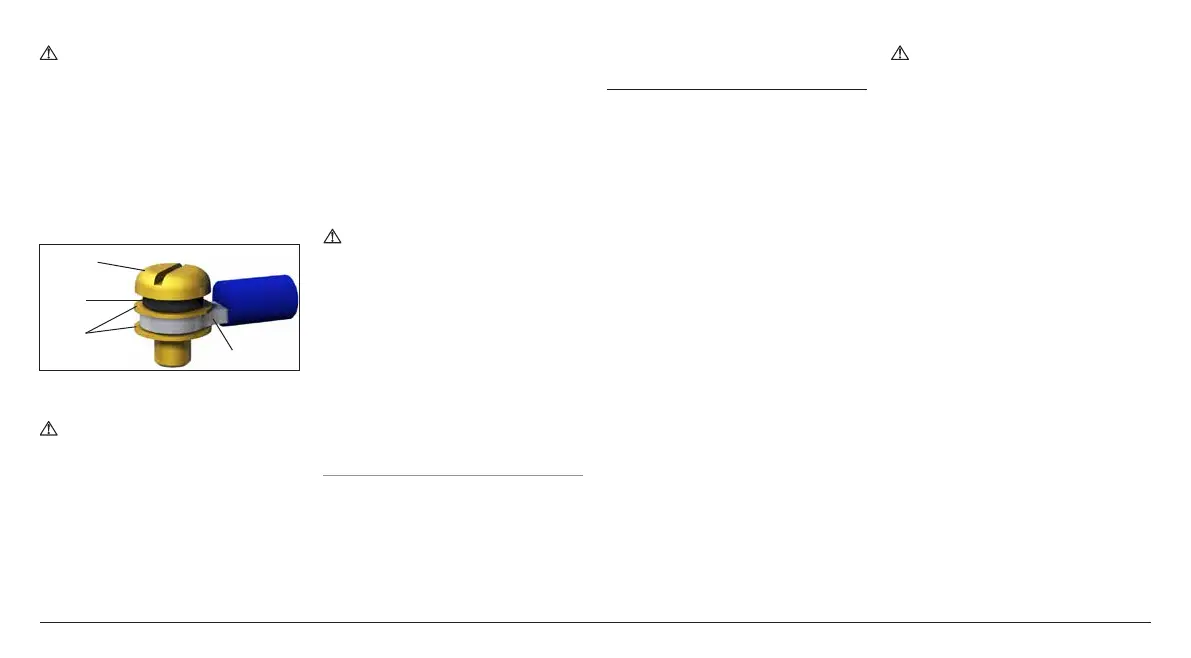

To ensure secure electrical

connections, it is important

that the requisite washers are

used as shown in Figure 7.5.1.

Failure to do so may result in

connections working loose or

screws not clamping down on

wire termination tags. Spring

washers must be compressed.

Screw tightening torques must not

exceed 1.5 Nm (1.1 lbf.ft)

4 or 5 mm

Pan Head

Spring

washer

Plain

washers

Wire tag

Fig. 7.5.1

To comply with Ex e certification,

terminals numbered 1 - 3 and earth

must be fitted with 1 off AMP

ring tag 160292 per terminal and

terminals numbered 4 - 47 must be

fitted with 1 off AMP ring tag 34148

per terminal when required.

Refer to the wiring diagram inside the

terminal cover to identify functions of

terminals. Check the supply voltage

is the same as that marked on the

actuator nameplate.

Remove power terminal guard.

Begin by connecting power cables and

replace guard. When all connections

are made ensure wiring diagram is

replaced in the terminal compartment.

WARNING: Wiring can reach

80

o

C in a 70

o

C ambient

temperature. For safety reasons

the same voltage level must be

connected to all the actuator's

indication terminals, remote input

terminals and digital I/O terminals

(if applicable).

All external circuits must be provided

with insulation suitable for the rated

voltage whilst considering national

regulations and statutory provisions.

7.6 Replacing Terminal Cover

Ensure cover O-ring seal and spigot

joint are in good condition and lightly

greased before refitting cover.

8. Commissioning - Basic

Settings

All actuator settings, Datalogger and

asset management data is accessed

using the supplied Rotork Bluetooth

®

Setting Tool Pro. Status and alarm data

in addition to that shown on the home

screen can also be accessed.

THE CONTROL COVER MUST

NOT BE REMOVED; NO USER

CONFIGURABLE SETTINGS ARE

AVAILABLE WITHIN THE CONTROL

ENCLOSURE. THE CONTROL

COVER IS SEALED BY A QUALITY

LABEL WHICH IF BROKEN MAY

INVALIDATE WARRANTY.

This instruction details the basic

settings that must be completed before

the actuator is put into service.

ELECTRICAL OPERATION MUST

NOT TAKE PLACE UNTIL THE BASIC

SETTINGS HAVE BEEN MADE AND

CHECKED.

The basic settings affect the correct

operation of the valve by the actuator.

If the actuator has been supplied with

the valve, the valvemaker or supplier

may have already made these settings.

Settings and operation must be

verified by electric operation and

function test of the actuated valve.

THIS PUBLICATION PROVIDES

INSTRUCTION ON MAKING THE

BASIC SETTINGS ONLY.

For instruction on control and

indication settings and for information

on diagnostics refer to PUB002-040.

Loading...

Loading...