IQ3 manual – Section: Preparing the Drive Bush 13

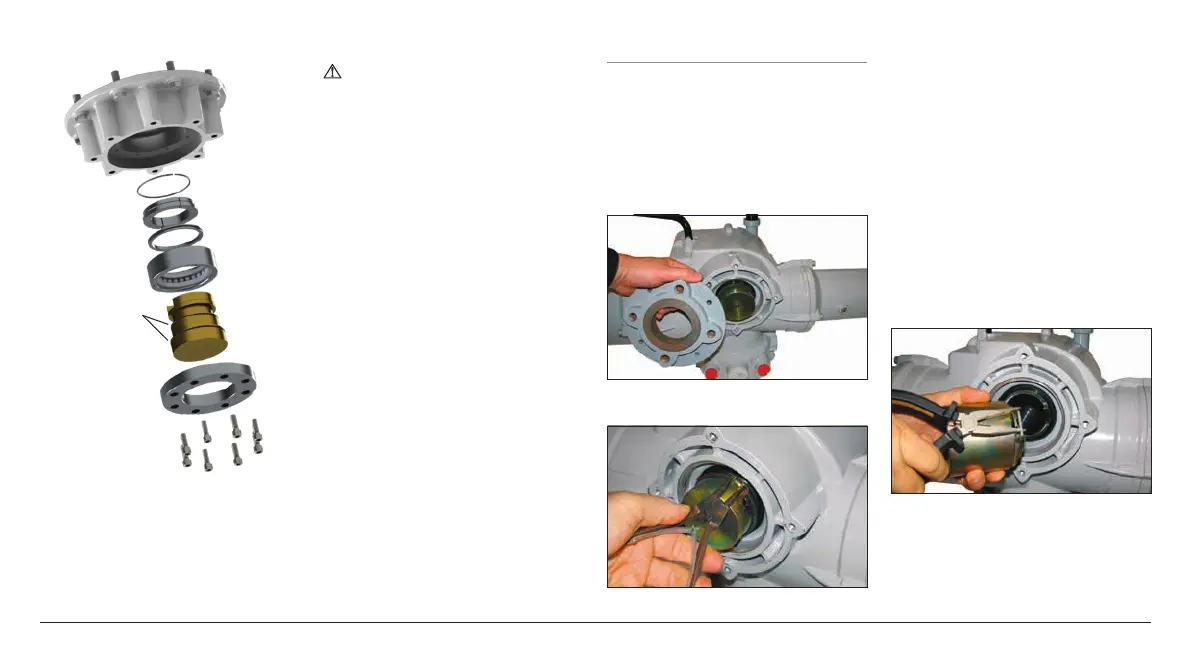

O-rings

4. Split Collar

6. Bearing Spacer

Ring

1. Retaining Plate

2. Drive Bush

3. Thrust Bearing

5. Snap Ring

Thrust Base

Housing

Fig. 5.1.4 F25 & F30 base assembly

Reassembly

WARNING: Failure to fully clean

and grease the drive bush and

O-rings before reassembly could

result in damage.

Remove all swarf from the drive bush

(2) ensuring all O-rings are undamaged,

clean and greased (for typical greases

refer to Section 11, weights and

measures).

Slide the bearing assembly (3) onto the

drive bush (2) and ensure it is fitted

down to the drive bush shoulder. On

size IQ20 to IQ95 refit bearing spacer

ring (6) into bearing assembly ensuring

O-ring is fitted and greased. Grease

and refit matched pair split collar (4)

and snap ring (5).

Grease and refit the drive bush bearing

assembly into the thrust base housing

on the actuator, ensuring that the slots

in the drive bush are located into the

drive dogs of the hollow output shaft.

Refit the retaining plate (1) and secure

with cap headed screws. For IQ40 to

IQ95 tighten base retaining screws to

the following torque values:

F25 / FA25 Base — 8 off / M12 cap

head screws: 89 Nm / 65 lbs.ft

F30 / FA30 Base — 10 off / M16 cap

head screws: 218 Nm / 160 lbs.ft

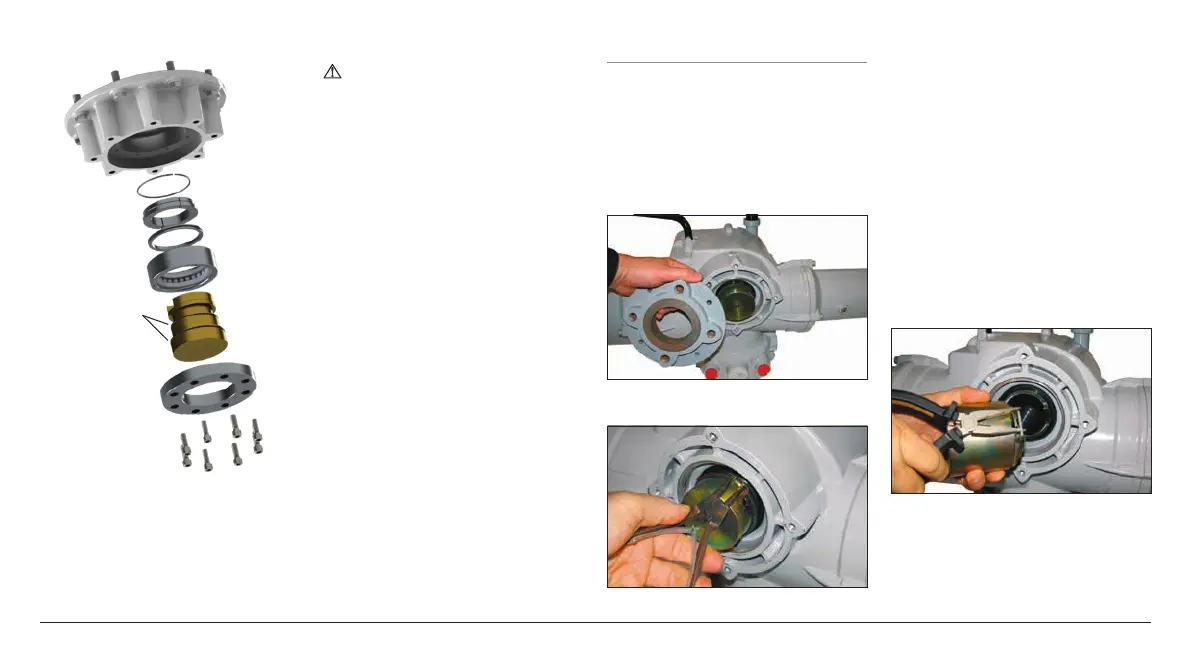

5.2 Non-Thrust Base Type B

All Sizes

Undo the hex head bolts securing the

base plate to the gearcase and remove

the base plate.

The drive bush and its retaining clip can

now be seen. The plate will vary with

the size of the actuator. See Fig. 5.2.1.

Fig. 5.2.1

Fig. 5.2.2

Types B3 and B4 Removal

Using external circlip pliers, expand the

circlip while pulling on the drive bush.

The drive bush will detach from the

actuator centre column with the circlip

retained in its grove. Refer to Fig. 5.2.2.

Types B1 Removal

The procedure for removal and refitting

of the B1 drive bush is the same as

for B3 and B4, however the circlip is

replaced with a custom spring circlip.

The spring operates in the same

manner as the B3/B4 circlip but is

expanded using long nose-pliers. Refer

to Fig. 5.2.3.

Fig. 5.2.3

Loading...

Loading...