IQ3 manual – Section: Cable Connections 17

6.7 IQL & IQML Adjusting Linear

Stroke

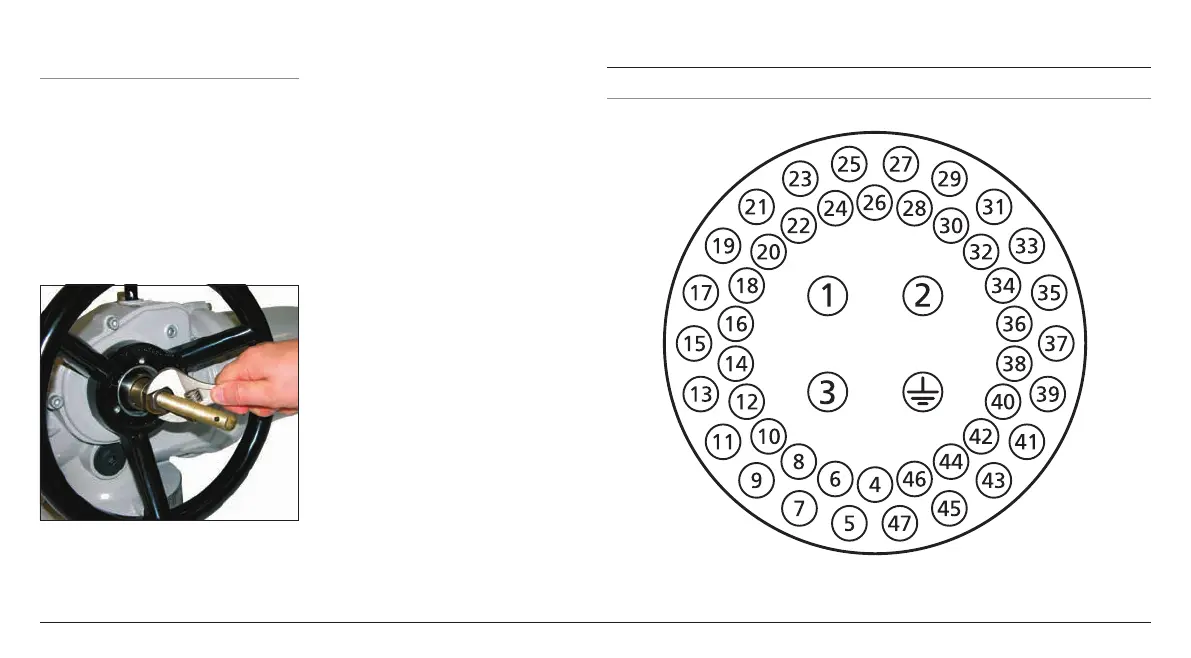

With the actuator securely fitted to

the valve, but with the linear drive

disconnected ensure valve is at its fully

closed (down) position.

Remove cover tube from actuator

handwheel, locate the down stop

adjustment on the linear drive unit and

with two spanners loosen the lock nut,

run the lock nut and tubular down

stop anti-clock wise to the end of the

thread.

Fig. 6.7.1

Turn the actuator handwheel

clockwise, the linear drive will move

down towards the valve spindle and

couple the linear drive to valve spindle.

Turn the tubular down stop clockwise

into the actuator until it comes to a

mechanical stop. If the valve must close

into its seat by TORQUE ACTION then

back off (anticlockwise) the down stop

by one third of one turn (equivalent to

1 mm). Run the lock nut down onto

the tubular down stop and tighten

with two spanners. There is no UP

STOP (open) on the linear drive unit,

the mechanical stop in the valve will

give this position. Refit the cover tube

onto the handwheel ensuring the

O-ring is fitted.

The linear drive unit is pre-packed with

extreme pressure multi-purpose grease

MULTIS MS2, use this or an equivalent

high temperature grease.

A grease nipple is situated in the base

of the actuator to enable lubrication of

the lead screw.

Periodically, depending on usage and

temperature, apply two pumps of the

grease gun.

7. Cable Connections

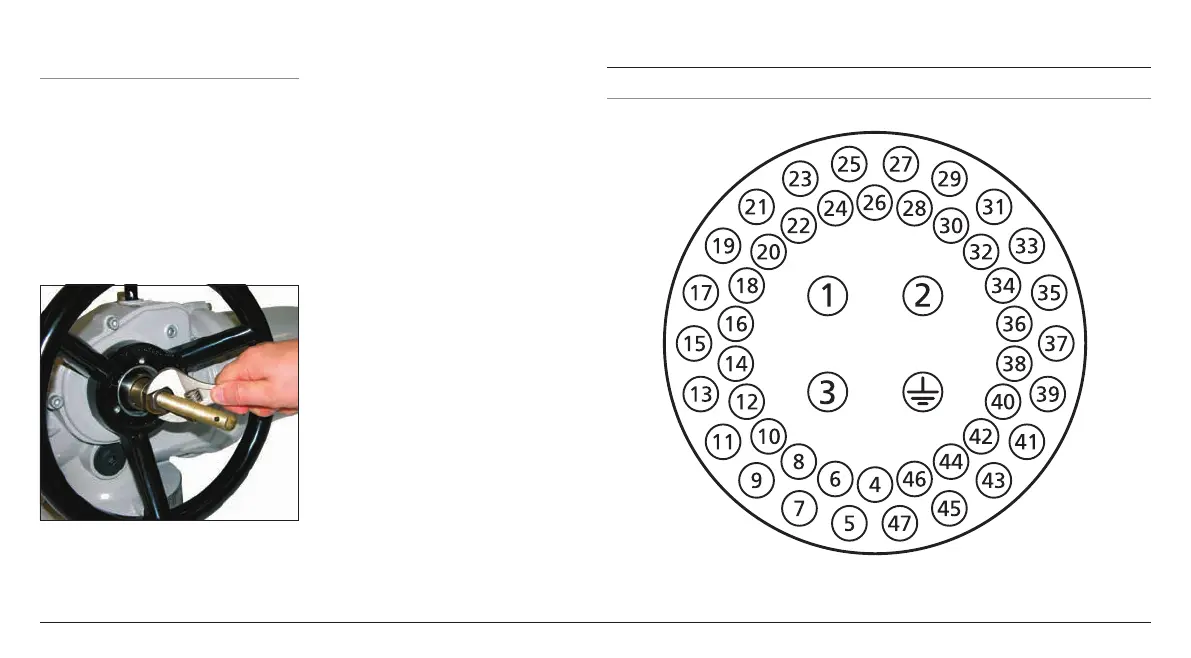

7.1 Terminal Block Layout

Fig. 7.1.1 Terminal numbers refer to connections as shown on the actuator circuit diagram

Loading...

Loading...