14 IQ3 manual – Section: Mounting the Actuator

6. Mounting the Actuator

Refer to Section 11 Weights and

Measures for actuator weight.

Ensure the valve is secure before fitting

the actuator as the combination may

be top heavy and therefore unstable.

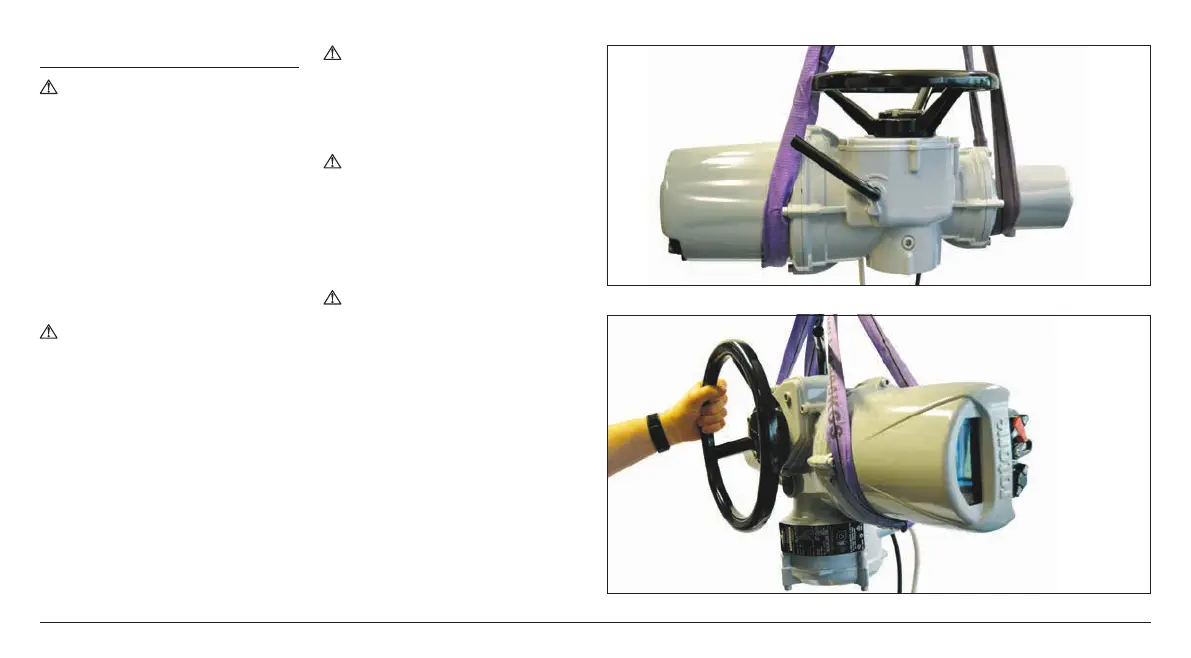

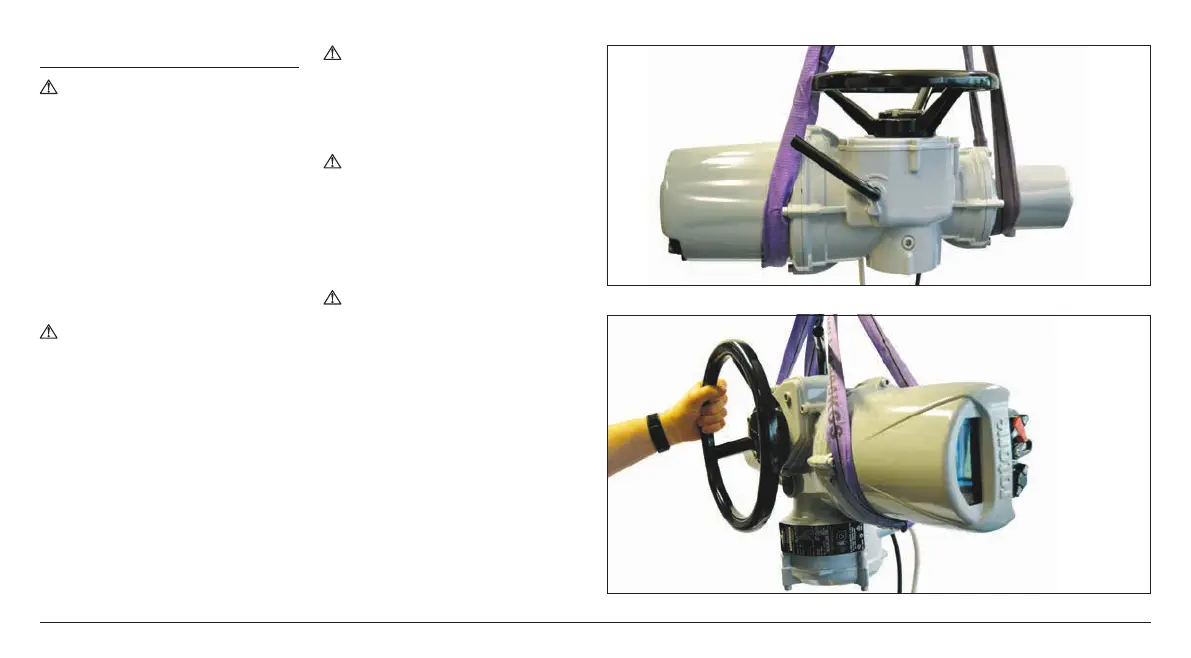

If it is necessary to lift the actuator

using mechanical lifting equipment

certified slings should be attached as

indicated in Fig. 6.2.1 for vertical shafts

and Fig. 6.2.2 for horizontal shafts.

At all times trained and experienced

personnel should ensure safe lifting

particularly when mounting actuators.

WARNING: The actuator should

be fully supported until full valve

shaft engagement is achieved and

the actuator is secured onto the

valve flange.

A suitable mounting flange confirming

to ISO 5210 or USA Standard MSS

SP101 must be fitted to the valve.

Actuator to valve fixing must confirm

to Material specification ISO Class 8.8,

yield strength 628 N/mm

2

.

WARNING: IQ Cover Tubes.

Cover tubes not supplied by Rotork

shall be designed to ensure that

they do not exceed BOTH mass

and moment parameters listed in

Section 11 Weights and Measures.

WARNING: Do not lift the

actuator and the valve combination

via the actuator. Always lift the

valve/actuator assembly via the

valve.

Each assembly must be assessed on an

individual basis for lifting.

WARNING: If the actuator

orientation when installed is

inverted (base up), additional oil

is required to ensure adequate

lubrication. The user should top up

the oil by the quantity stated in the

table under section 11 Weights and

Measures. Failure to do will cause

premature wear.

Fig. 6.2.1

Fig. 6.2.2

Loading...

Loading...