Weigh Cell Operating Instructions 31

Operation

8 Operation

8.1 Notes on “Analytical Weighing”

with Weigh Cells

8.1.1 Handling of Samples and Vessels

The sample should be acclimatized to the temperature

of the weigh cell.

This is the only way to avoid measurement errors caused

by air buoyancy and fluctuations resulting from

convection currents across the surface of the sample.

These negative effects increase as the volume and/or

surface area of the sample increases. For this reason, the

size of the tare container should be appropriate for the

sample.

Samples and vessels for weighing should not be

touched by the operator’s hands. since the hygroscopic

effect of fingerprints and the effect of the hand’s

temperature can influence the measurement results.

The sample must be applied carefully, e.g., manually

using tweezers or automatically via a robot or a filling

system.

When designing a draft shield device, steps must be

taken to keep the increase in temperature within the

weighing chamber to a minimum (e.g., using a bypass).

8.1.2 Weighing Electrostatically Charged

Samples and Vessels

Significant measurement errors may occur when

weighing electrostatically charged objects. This problem

particularly involves samples that have extremely poor

conductivity (glass, plastic, filters) since they can only

discharge electrostatic—i.e., friction-induced—charges

through the weighing pan over a relatively long period

of time.

The result is a force acting between the charge on the

sample and the permanently installed parts of the weigh

cell. This causes the displayed weight value to fluctuate

constantly.

Ionization can be applied to make the air around the

sample conductive. This enables the charge to be

compensated through the air, or discharged through the

ground (grounded).

Aside from purely mechanical solutions (e.g., using a

special weighing pan to shield the sample), bombarding

the sample with ions of opposing polarity to neutralize

the surface charge is one of the most effective methods

for eliminating static electricity. We also supply

corresponding components for installation in systems.

The area around the weigh cell (e.g., plastic parts) can

also contain charges that negatively affect the accuracy

of weighing results. Take appropriate steps (grounding)

when designing draft shield devices.

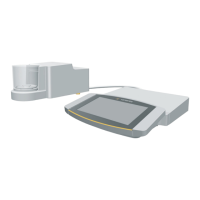

On the reverse of the

weigh cell mounting

plate, thread M6 (1) is

available for a poten-

tial equalization con-

ductor (e.g., for a

spatula).

t It must be ensured

that the frame is

grounded.

8.1.3 Weighing Magnetic or Magnetizable

Samples

It is technically impossible to avoid using magnetizable

materials for the production of weigh cells. This is

primarily because the operating principle of high-

resolution weigh cells is based on compensation of the

load through magnetic forces.

When weighing magnetic or magnetizable samples or

vessels, interaction between the sample or vessel and

the above-mentioned parts inside the weigh cell may

have a distorting effect on the weighing results.

To keep such effects to a minimum, we recommend

increasing the distance between the sample/container

and the weighing system using a non-magnetic material.

The force is reduced quadratically with the increase in

distance.

Magnetizable/magnetized samples and the weigh cell

interact with magnetic fields and with magnetizable or

magnetized parts in the environment. The system can

be shielded from external magnetic fields to some

extent using (soft magnetic) plates.

1

Loading...

Loading...