4 Checking and Performing Printer Adjustments

63

CL4NX/CL6NX Service Manual

4.13

Adjusting the Position of the Media Sensor

If you used standard media, you do not need to adjust the media sensor (I-mark sensor and Gap

sensor).

*During shipment from the factory (default settings), the media sensor guide is set to the innermost

position, and is to be used for the standard media.

When you use nonstandard media (for example, media with printing on the underside, or media with a

special shape), the media sensor cannot sense the I-mark or Gap of the media correctly. In such a case,

adjust the position of the media sensor to sense the I-mark or Gap correctly.

About the media sensor

The I-mark sensor and Gap sensor are mounted on the same PCB and move simultaneously.

The media guide is attached to these sensors, the mark shows the I-mark sensor position and the

mark shows the Gap sensor position.

The adjustment ranges are as follows:

With the inner side of the printer as reference (left side of the media when looking from the printer front),

For CL4NX printer

• I-mark sensor position: 6.3 mm to 59.6 mm (0.2” to 2.3”)

• Gap sensor position: 13.3 mm to 66.6 mm (0.5” to 2.6”)

For CL6NX printer

• I-mark sensor position: 8.0 mm to 73.0 mm (0.3” to 2.9”)

• Gap sensor position: 25.0 mm to 90.0 mm (1.0” to 3.5”)

The adjustment procedure is as follows:

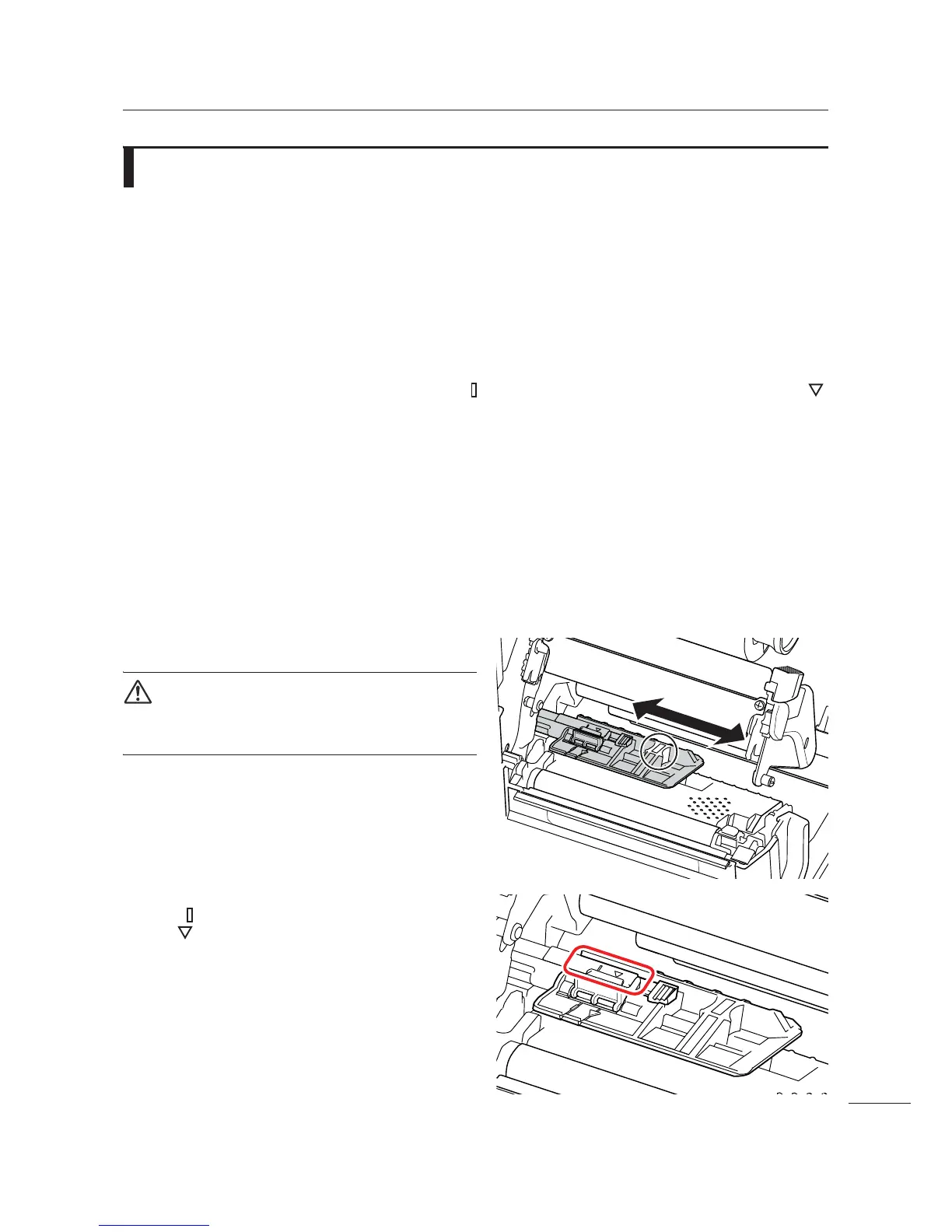

1 Open the top cover of the printer.

CAUTION

Open the top cover fully to prevent accidental drop of the

cover.

2 Push the head lock lever towards the rear

to unlock the print head.

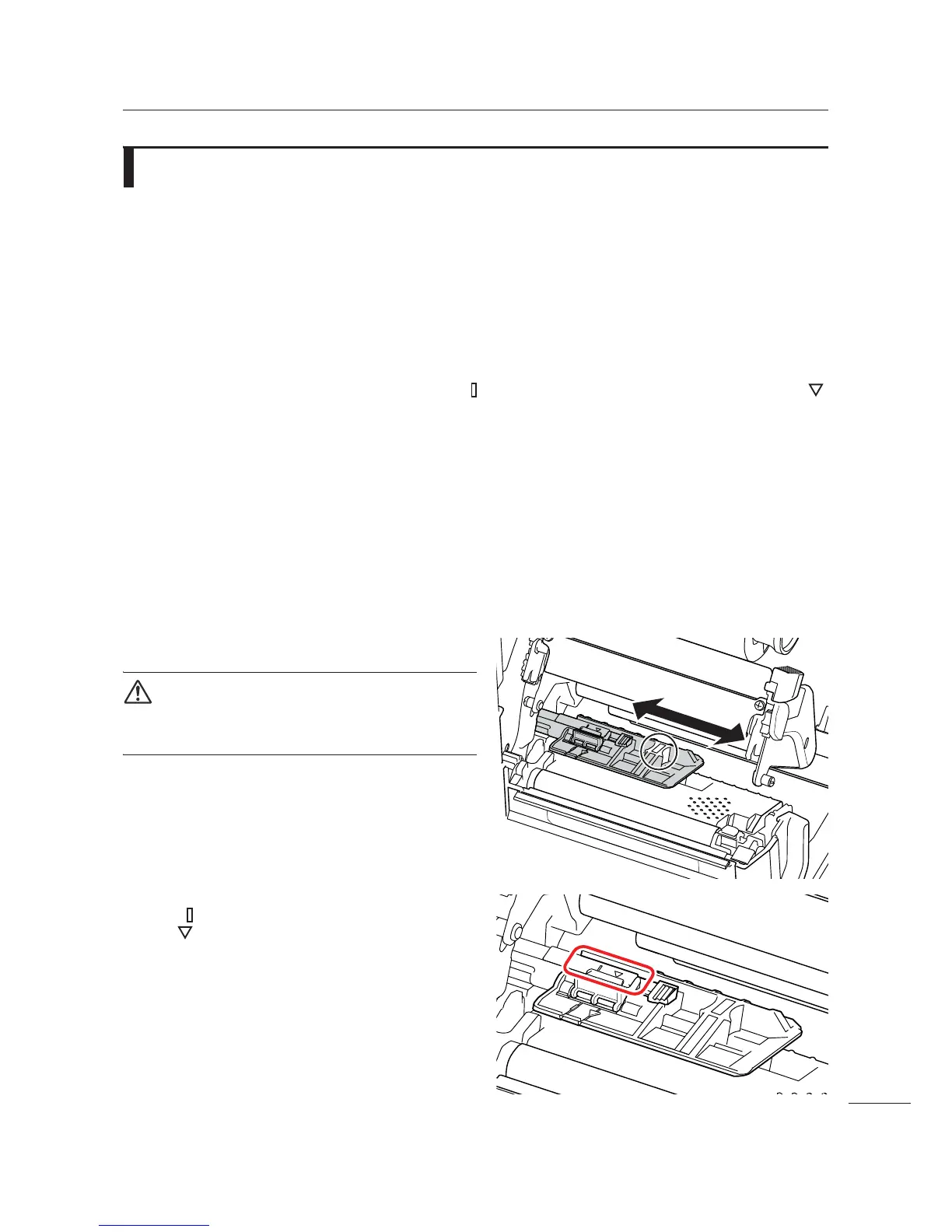

3 Adjust the media sensor guide to the

position where it can sense the I-mark or

Gap of the media.

The mark shows the I-mark sensor position and

the mark shows the Gap sensor position.

Loading...

Loading...