7 General Description of Functions

34 / 86 EN-US · 30.30.00.00424 · 07 · 10/23

7.6Blow off Functions

The ejector has three blow off functions in three different modes. The function is set under the [blo]

menu item in the configuration menu or via IO-Link.

Explanations of the blow off modes:

Description Explanation

Externally controlled blow

off

[bL0] => [-E-]

The ejector switches to blow off mode for as long as the blow off signal

is present.

The blow off signal is given priority over the suction signal.

Internally time-controlled

blow off

[bLo] => [l-t]

After the suction signal is switched off, the ejector switches to blow off

mode automatically for the set time (which can be adjusted using

[tbL]). With this function, the blow off signal does not have to be ad-

ditionally controlled.

“Blow off” mode can still be activated in this mode using the “Blow

off” signal input.

The blow off signal overrides the suction signal, even if the specified

blow off time is very long.

The [L-t] function is not available for ejector variant IMP.

External time-controlled

blow off

[bLo] => [E-t]

The blow off starts with the blow off signal and is performed for the

set time period [tbL]. Applying the blow off signal for a longer time

does not lead to a longer blow off period.

The blow off signal overrides the suction signal, even if the specified

blow off time is very long.

The length of the blow off time [tbL] is set in the main menu. This menu item is suppressed in operating

mode [-E-].

The number displayed indicates the blow off time in seconds. Blow off times from 0.10seconds to

9.99seconds can be set.

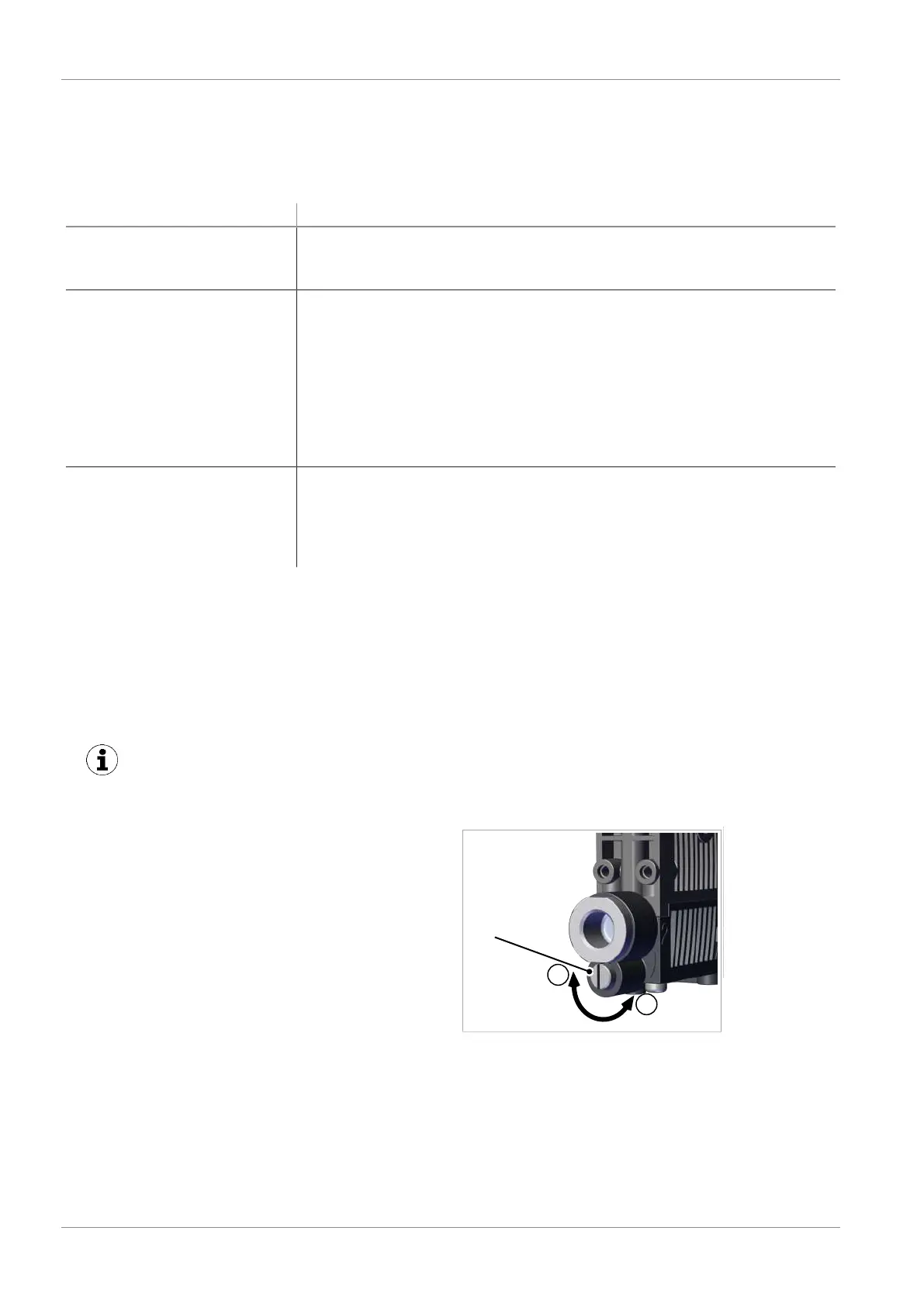

7.7Changing the Blow-Off Flow Rate on the Ejector

Do not overwind past the stop on the valve screw. A minimum flow rate of approx. 10% is al-

ways necessary for technical reasons. The blow off volume flow can be set between 10% and

100%.

The figure shows the position of the valve screw

(1) for adjusting the blow off flow rate. The valve

screw is equipped with a stop on both sides.

• Rotate the valve screw (1) clockwise to reduce

the flow rate.

• Rotate the valve screw (1) counterclockwise to

increase the flow rate.

Loading...

Loading...