7 General Description of Functions

42 / 86 EN-US · 30.30.00.00424 · 07 · 10/23

7.24Energy and Process Control (EPC)

In IO-Link mode, the energy and process control (EPC) function is available. It is subdivided into three

modules:

• Condition monitoring (CM): Condition monitoring to increase system avail-

ability

• Energy monitoring (EM): Energy monitoring to optimize the vacuum sys-

tem’s energy consumption

• Predictive maintenance (PM): Predictive maintenance to increase the perfor-

mance and quality of the gripping systems.

7.24.1Condition Monitoring (CM)

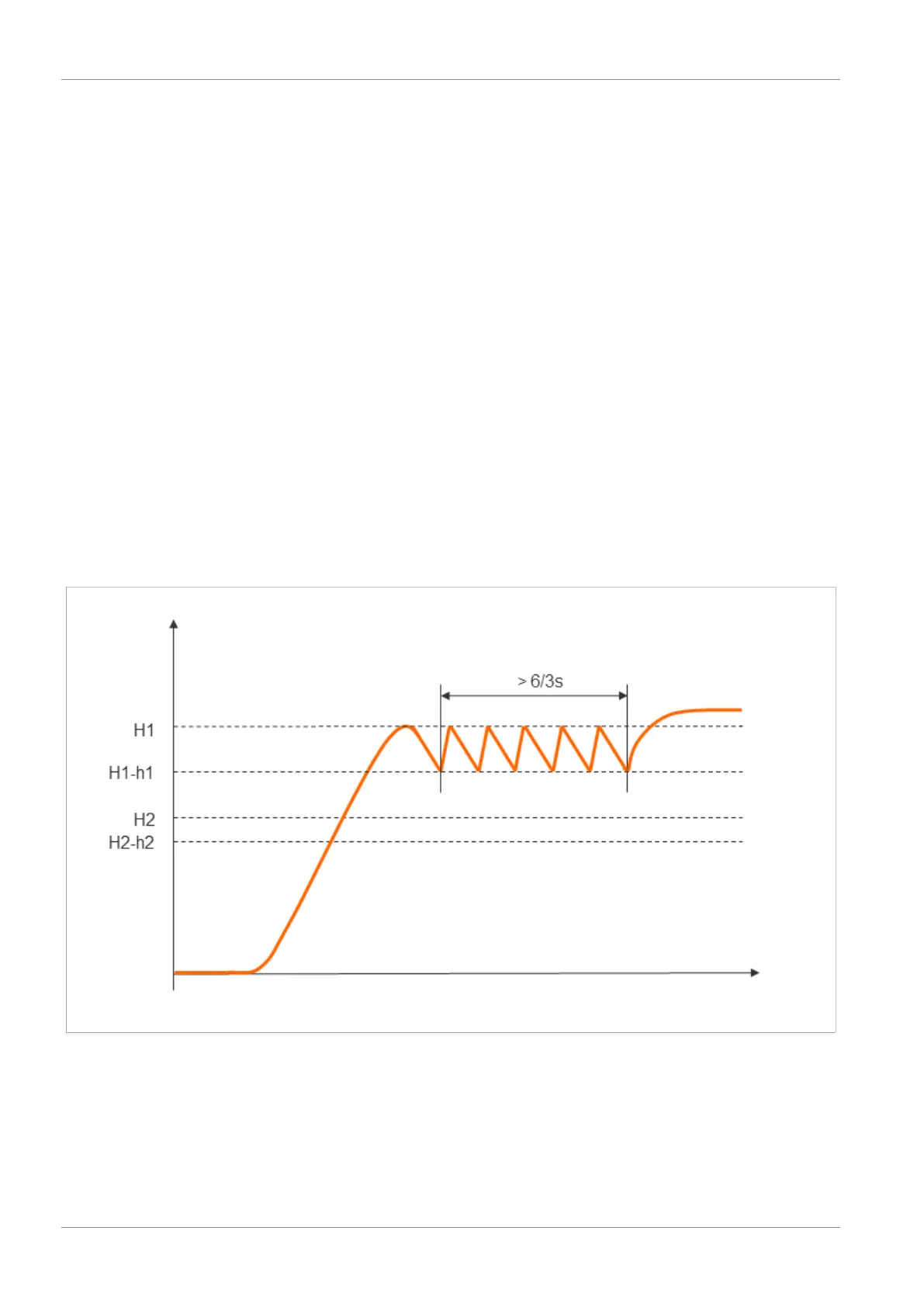

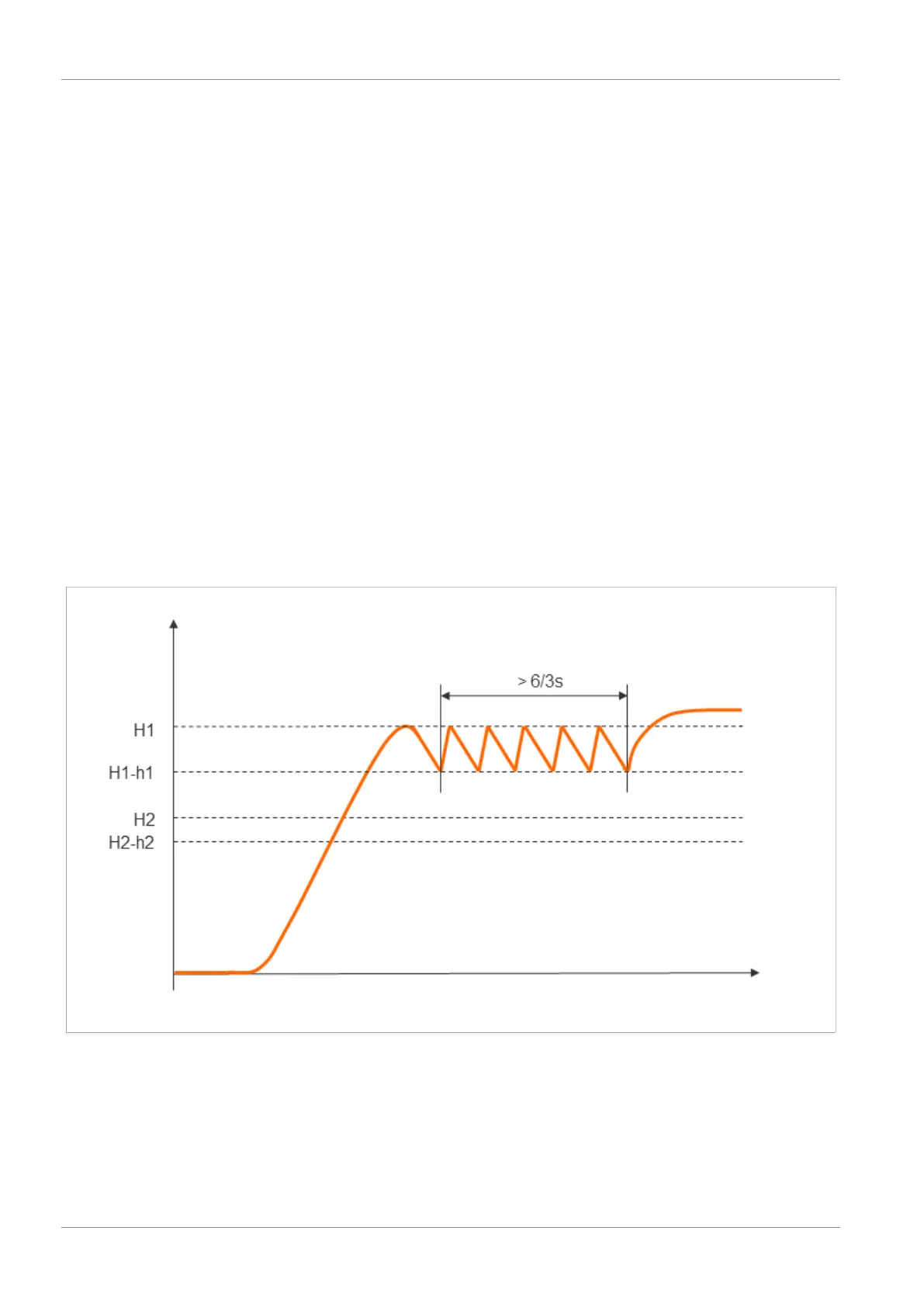

Monitoring the valve switching frequency:

When the air saving function is activated and there is a high leakage level in the gripping system, the

ejector switches between the suction and suction-off states very frequently. The number of valve switch-

ing procedures thus increases rapidly within a short time. To protect the ejector and increase its service

life, the ejector switches the air saving function off automatically at a switching frequency of more than 6

times every 3 seconds and activates continuous suction; the ejector then remains in the suction state. In

IO-Link mode, the appropriate condition monitoring warning is also set. In addition, the system status

light switches to yellow.

The basic monitoring for the valve protection function is also active in SIO mode.

Schematic diagram of the valve switching frequency

Vacuum

[mbar]

Time [s]Suction ON

With the [dC5 = on] setting, continuous suction is deactivated, and the ejector continues in control

mode despite a high leakage rate or control frequency greater than 6 times per 3s.

Loading...

Loading...