12 Warnings and Errors

EN-US · 30.30.00.00424 · 07 · 10/23 63 / 86

12Warnings and Errors

12.1Error Messages in SIO Operation

When a known error occurs, this is reported in the form of an error number. In SIO mode, error messages

are shown on the display. An “E” followed by the error number appears on the display.

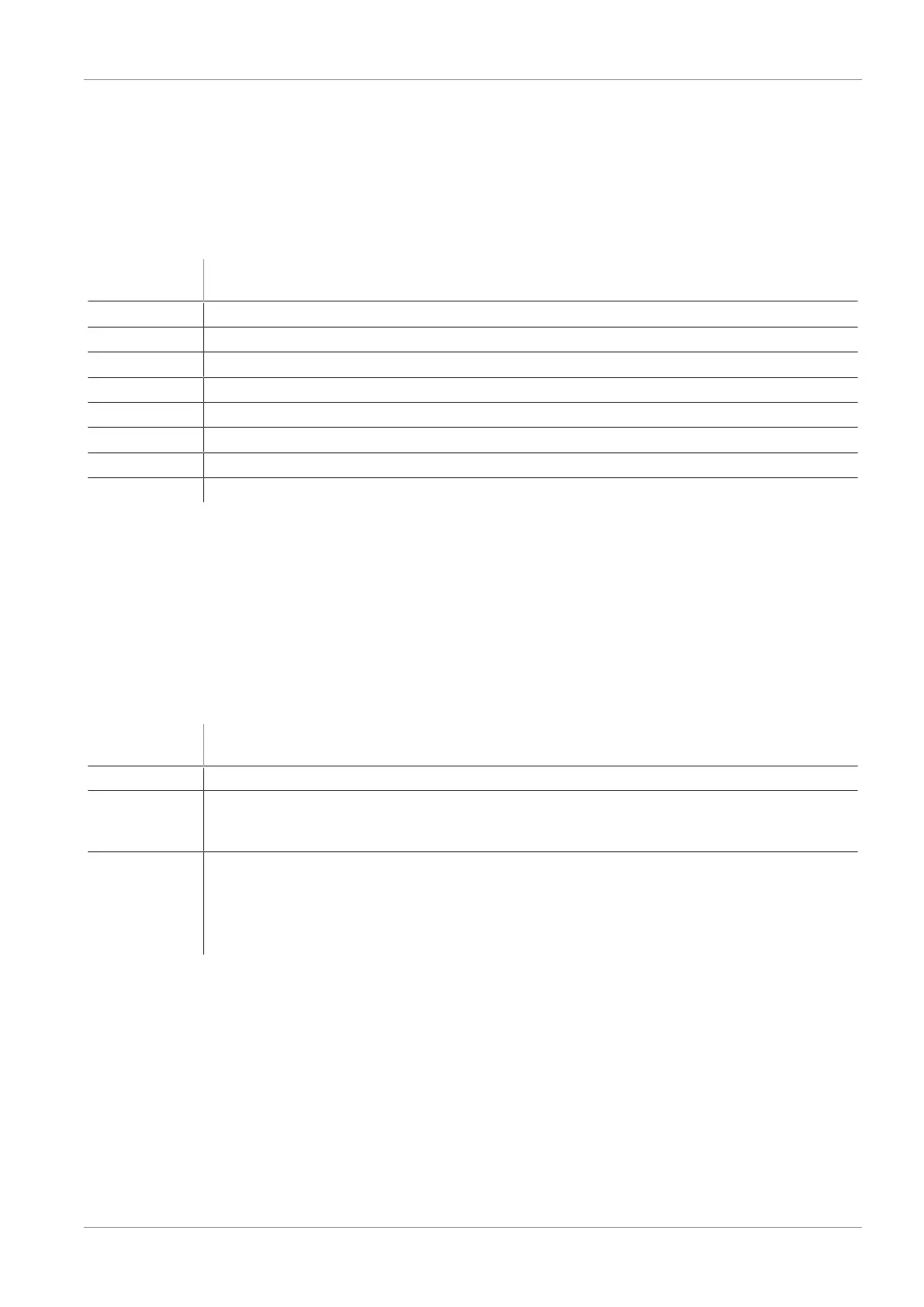

The following table shows all the error codes:

Code dis-

played

Explanation

E01

Electronics error – internal data management, EEPROM

E02

Electronics error – internal communication

E03

Zero-point adjustment of the vacuum sensor outside ± 3% FS

E07

Supply voltage is too low

E12

Short circuit on output 2

E17

Supply voltage is too high

FFF

Present vacuum exceeds the measurement range

-FF

Overpressure in vacuum circuit; this normally happens exclusively in Blow off mode.

The error [E01] remains on the display after being shown once. Delete the error by switching off the

power supply. If this error occurs again after the power supply is switched back on, then the device must

be replaced.

12.2System Status Light in IO-Link Mode

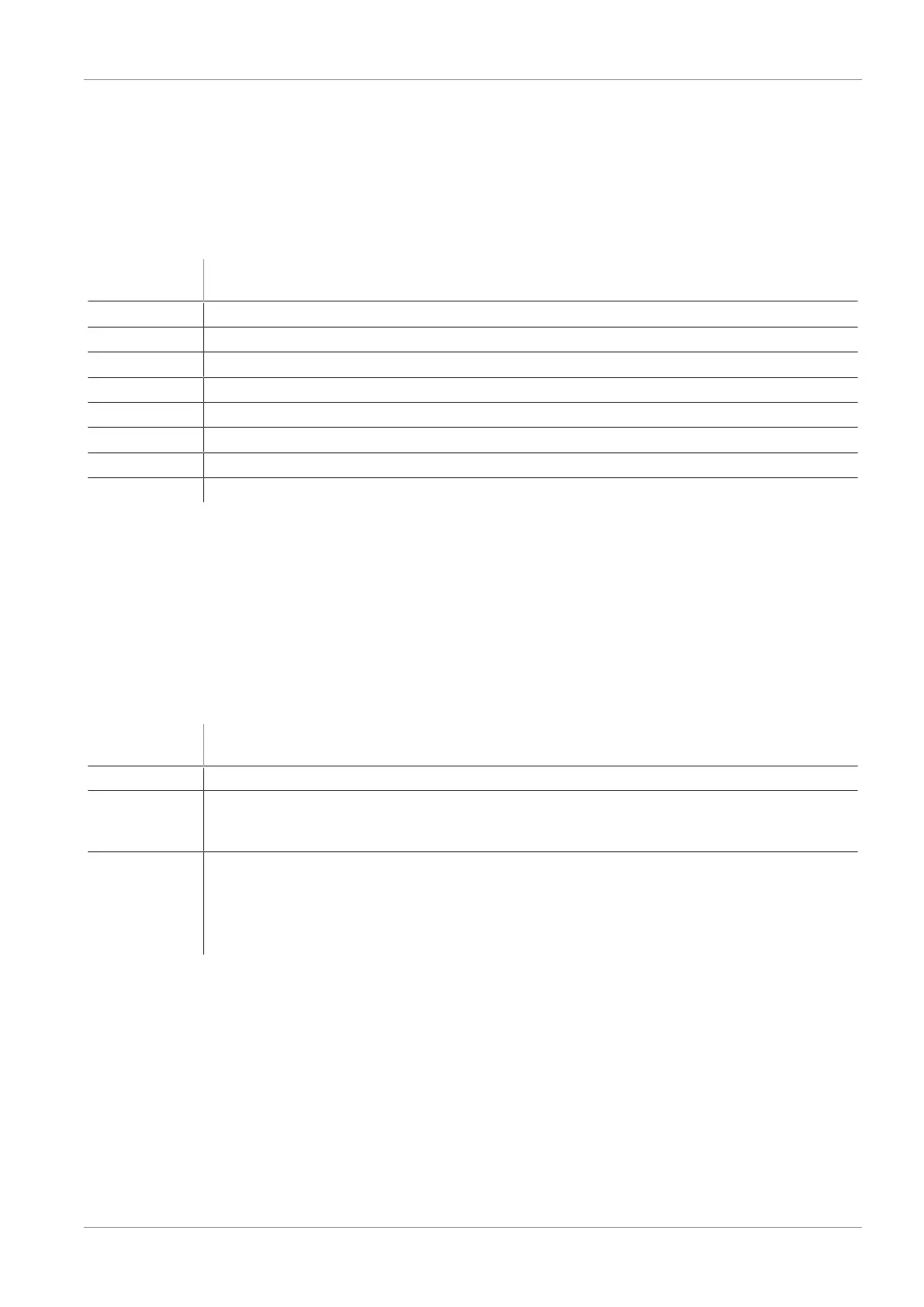

The overall status of the ejector system is displayed as a traffic light using 3 bits in process data input byte

0. All warnings and errors are taken into account when defining the status of the traffic lights.

This basic display provides immediate information about the status of the ejector with all its input and

output parameters.

System sta-

tus displayed

Description of the status

Green System is working perfectly with optimal operating parameters

Yellow Warning – Condition monitoring warnings in place; ejector system not functioning per-

fectly

Check operating parameters

Red Error – Error code provided in parameter error; safe operation of the ejector within the

operating limits is no longer ensured

• Cease operation

• Check the system

12.3Warnings and Error Messages in IO-Link Mode

In IO-Link mode, further status information is available in addition to the error messages displayed in SIO

mode.

Any condition monitoring events that occur during the suction cycle cause the system status light to im-

mediately switch from green to yellow. The specific event that caused this switch can be seen in the “Con-

dition monitoring” IO-Link parameter.

Any condition monitoring events that occur during the suction cycle cause the system status indicator

light to immediately switch from green to yellow/orange. The event that caused this switch can be seen in

the “Condition monitoring” IO-Link parameter.

Loading...

Loading...