Revision: 3.0 Page 41 of 70

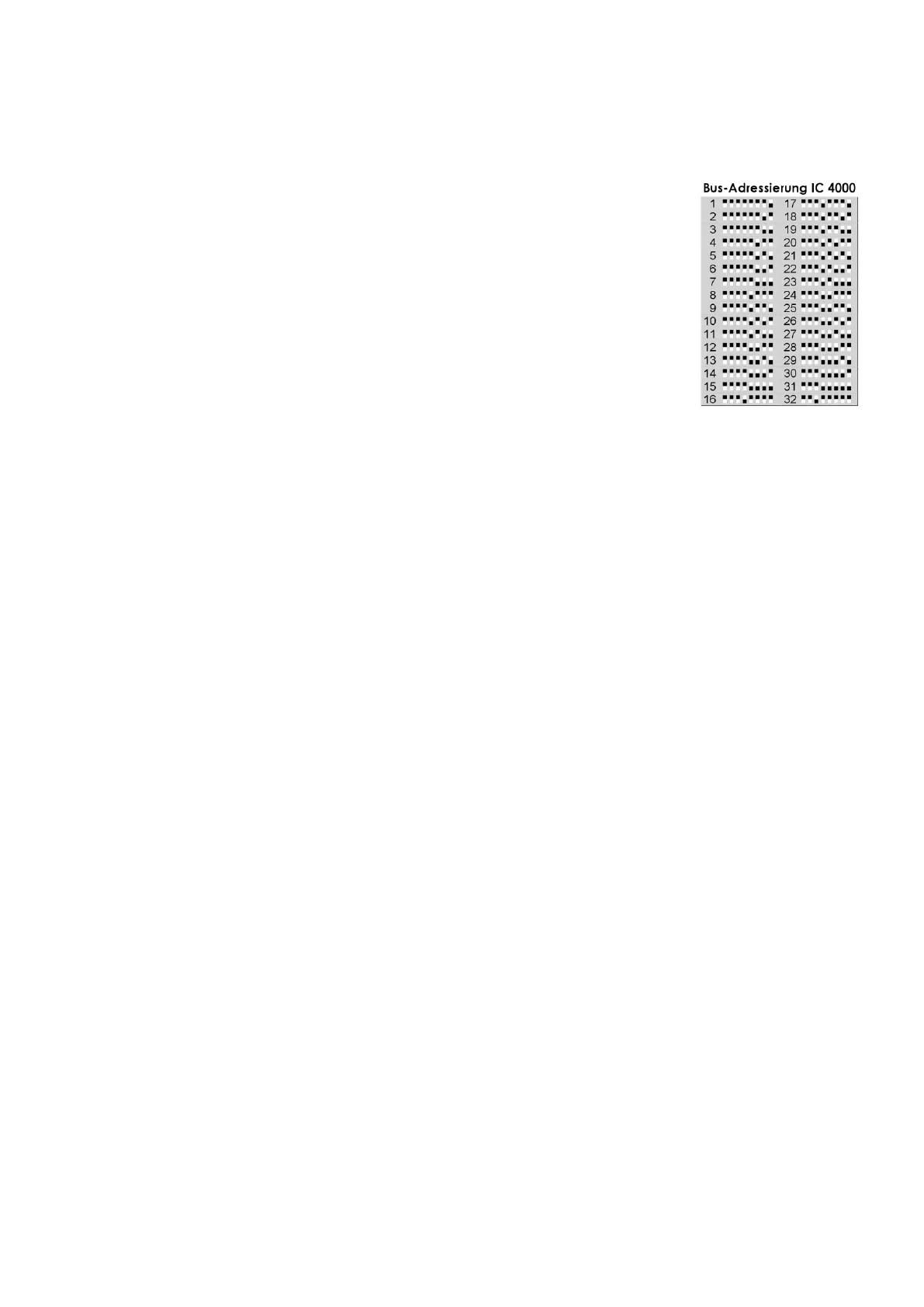

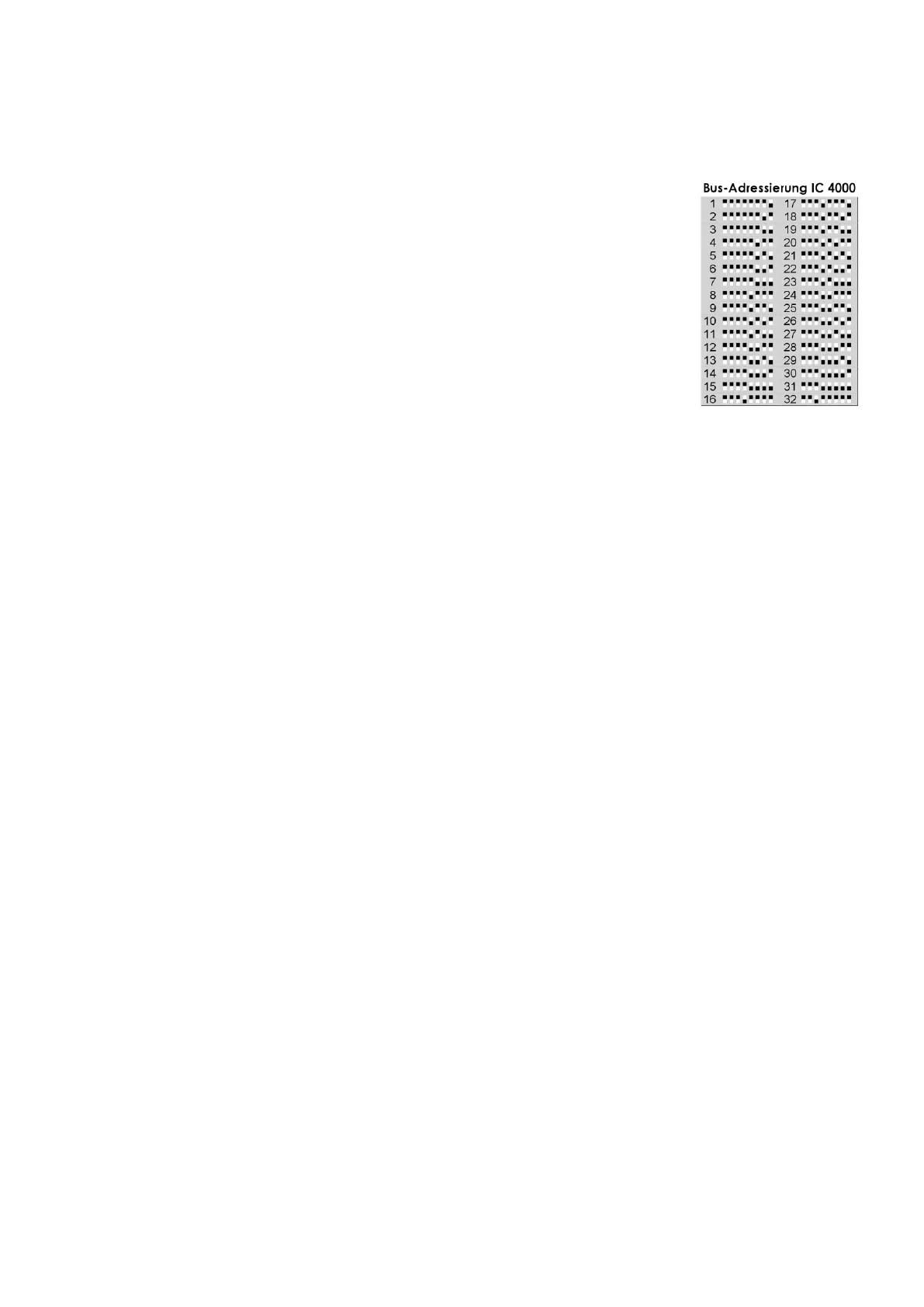

Assigning MODBUS addresses

It is essential that each IC 4000 automatic burner control unit

[for MODBUS communication with the SchwankControl central control],

is assigned a unique MODBUS address.

The MODBUS address is set via DIP switch

in the lower right corner of the board.

A maximum of 32 addresses can be assigned per zone.

All IC 4000s are delivered with the MODBUS address 1.

Figure 41: [MODBUS addressing]

IC 4000 delivery status

The automatic burner control unit is parameterised for MODBUS communication in the as-

delivered state.

When used in systems with relay control, the parameterisation must be adapted accordingly

[see separate operating manual of the Schwank heaters used].

Please note that the wiring of the GDM plug must also be changed when used in systems with

relay control.

Loading...

Loading...