Section 04 ENGINE (2-STROKE)

Subsection 07 (EXHAUST SYSTEM)

Expansion Pipe and Muffler

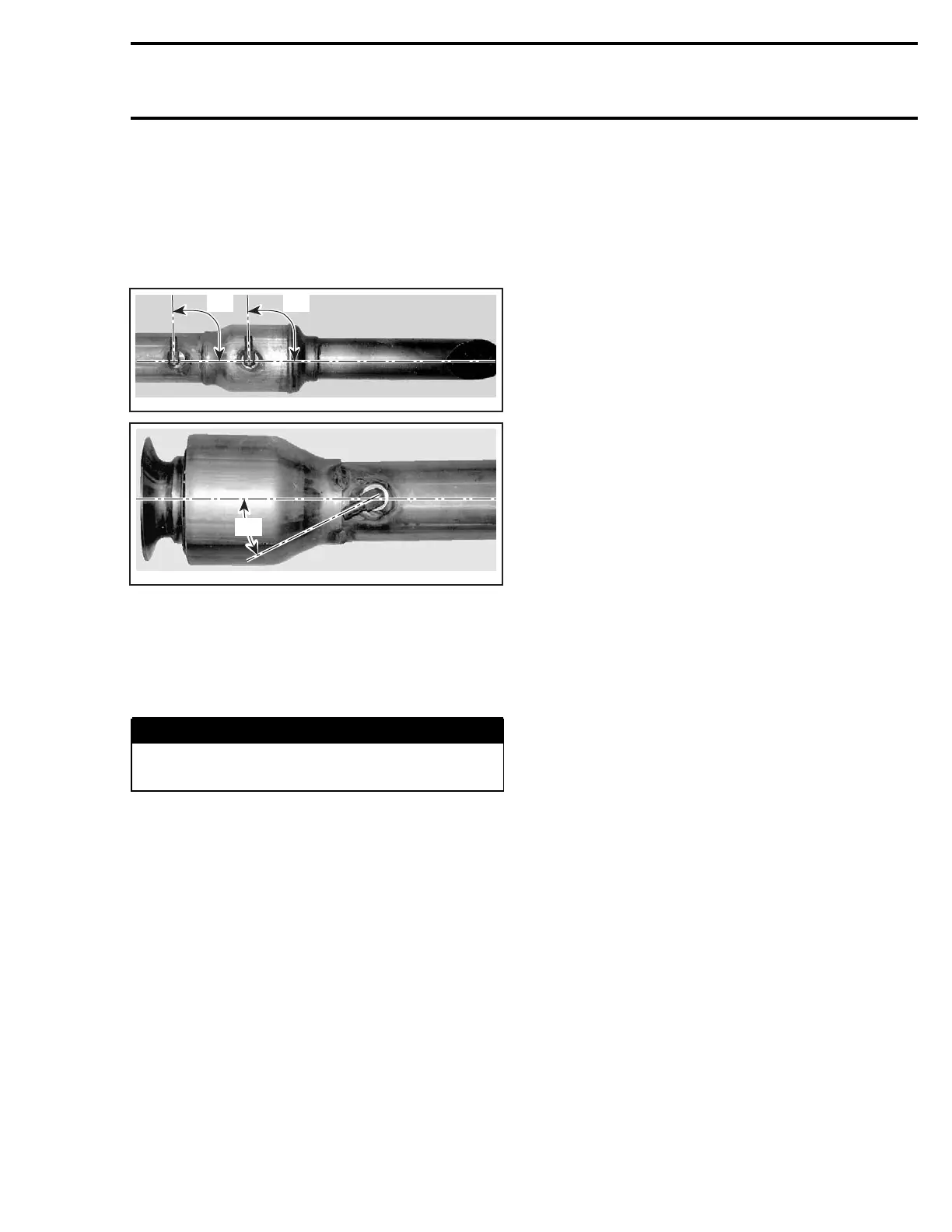

Apply Loctite 592 on threads of fittings no. 11.

Tighten fittings to 5 N•m(44lbf•in) then position

as per following illustration. Do not screw more

than 1 turn while positioning. Do not unscrew to

reposition.

F22D0IA

90° 90°

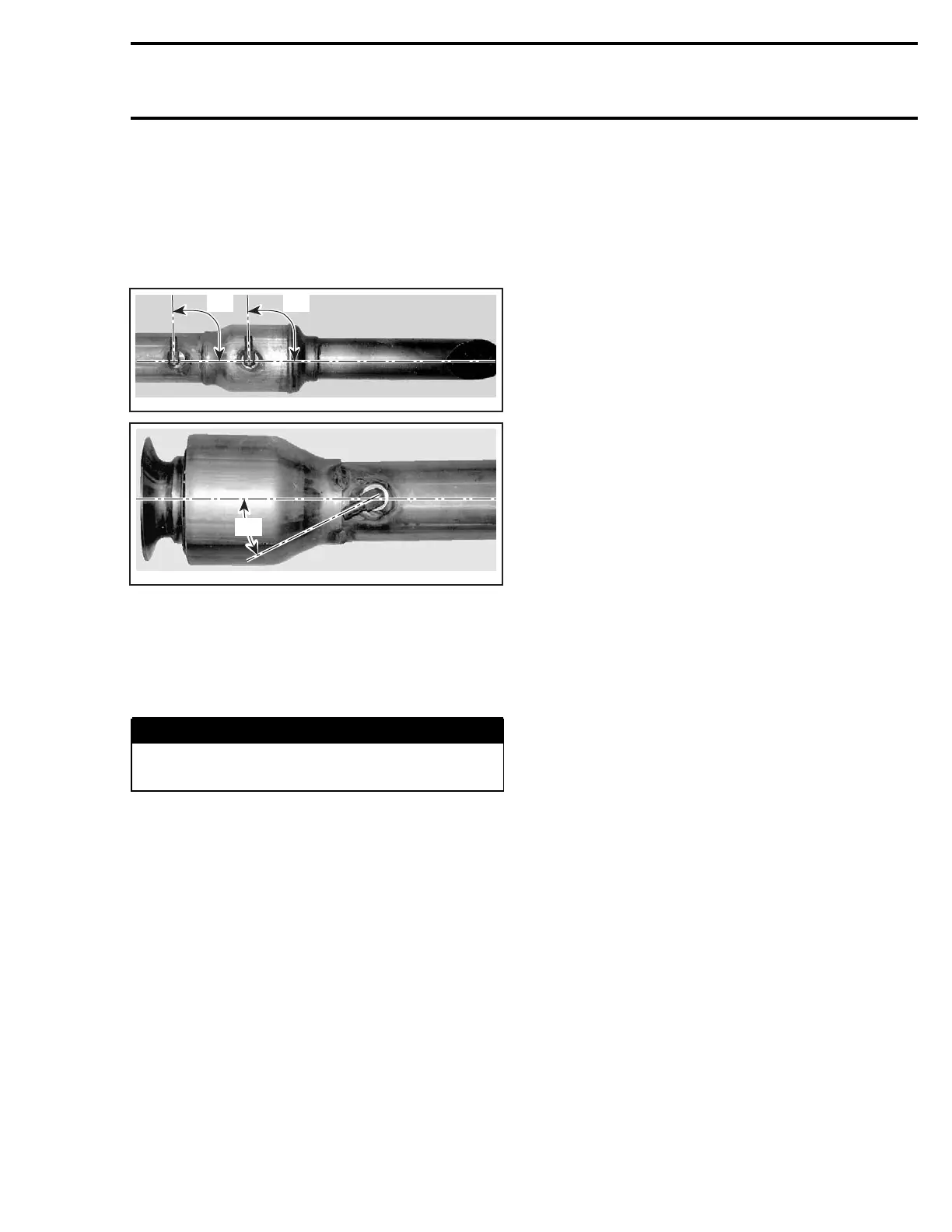

F22D0JA

30°

Pressurize the wall jacket to 103 kPa (15 PSI)

through the fittings. No leak should occur.

Position muffler no. 15 in its location. Do not in-

stall the strap and the small clamp yet.

Insert expansion pipe in its position.

WARNING

Pay attention not to bend injection oil cable

or throttle cable.

Loosely install a NEW clamp no. 2.

CAUTION: Those clamp type are not designed

to be removed and reinstalled many times. Re-

installing a used clamp is likely to fail.

Reinstall hoses to T-fittings no. 11. Rear hoses

can be connected on any fitting. Ensure to keep

the same hose routing (inverted U shape).

CAUTION: If hoses length or routing were

changed, water ingestion might occur when

watercraft tips over.

Strongly push expansion pipe toward muffler to

insert it into bellow no. 16.

smr2004-3D 19

Loading...

Loading...