Section 04 ENGINE (2-STROKE)

Subsection 07 (EXHAUST SYSTEM)

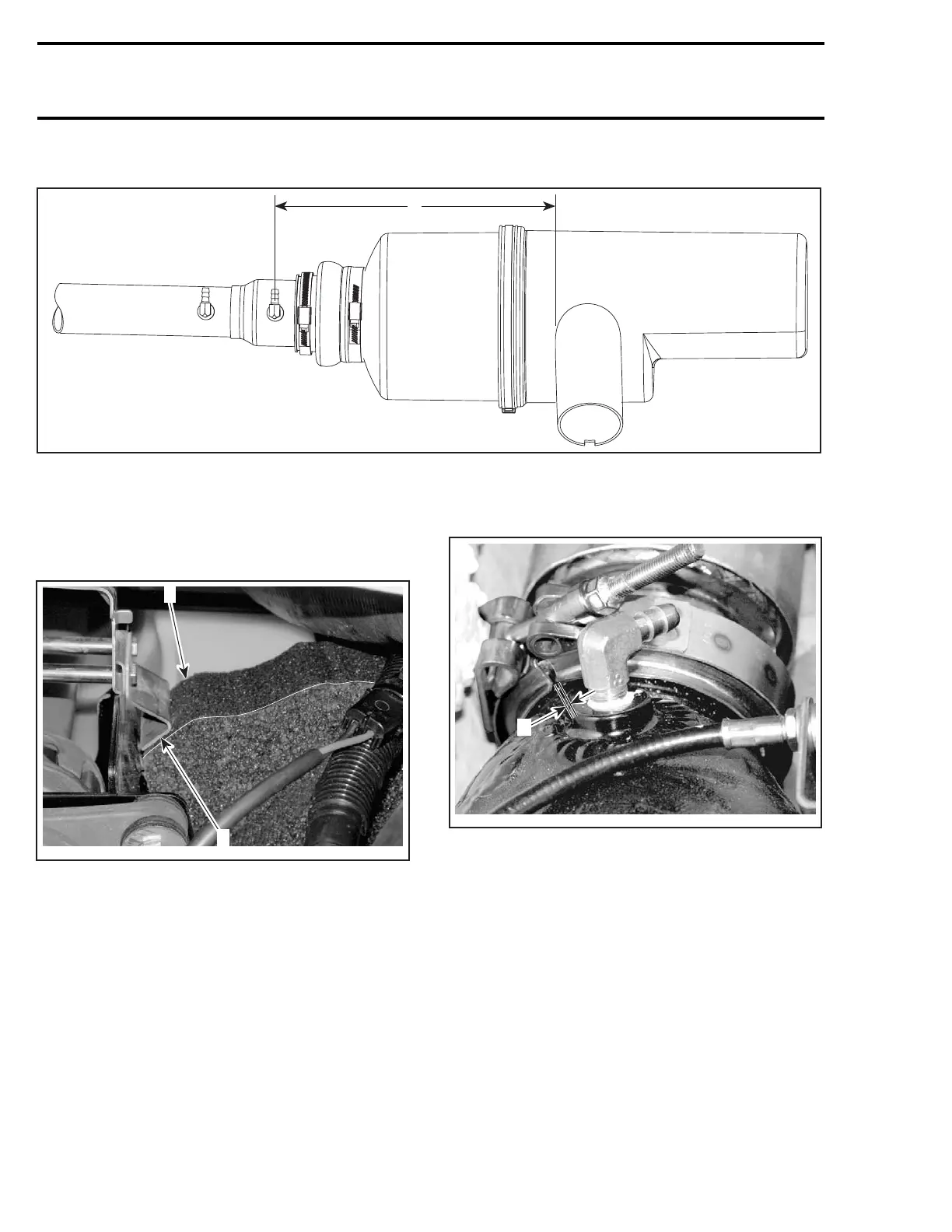

To ensure pipe end is well inserted in muffler, measure the distance as shown in the following illustration.

F22D0KS

A

A.322mm(12.68in)

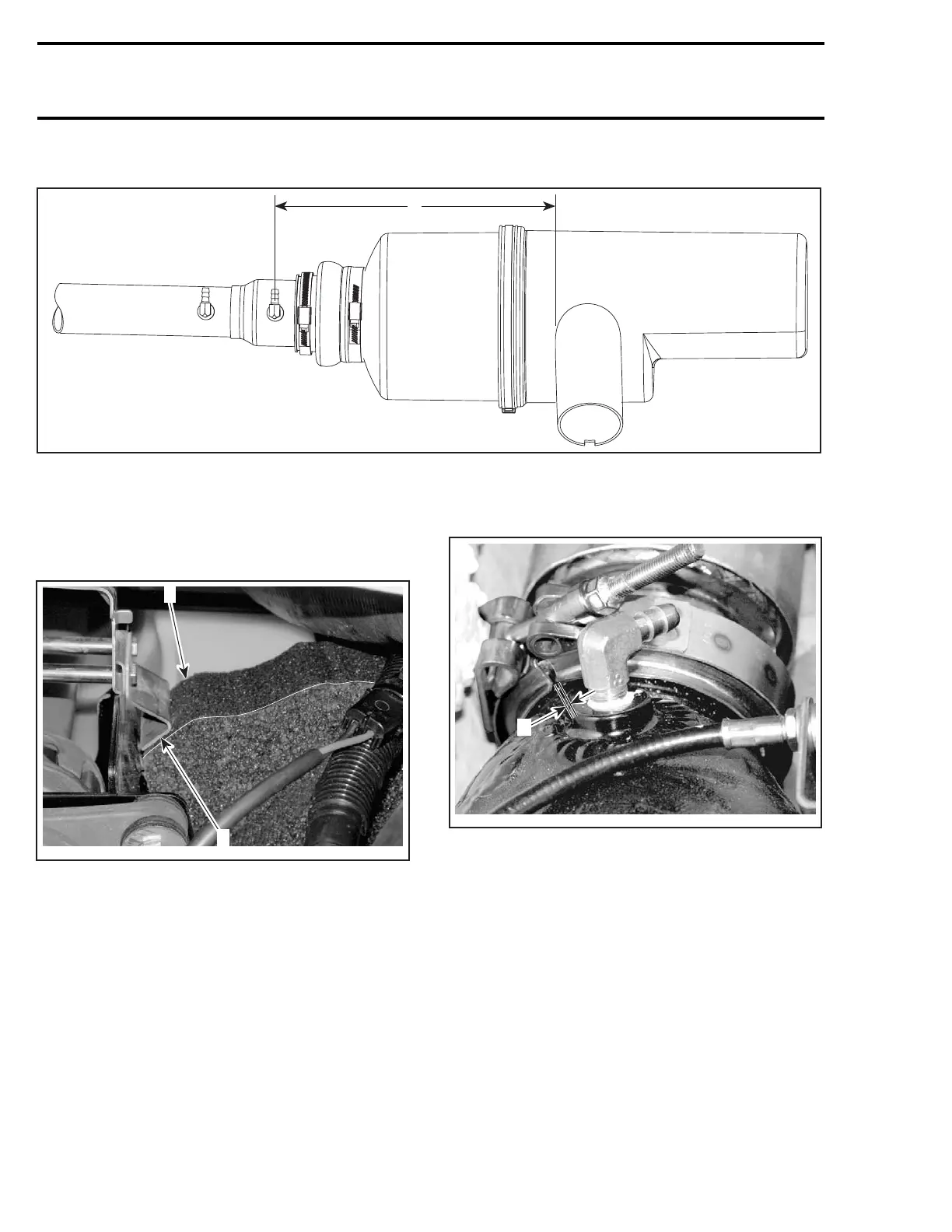

Insert foam under expansion pipe. Ensure foam

is not against muffler bellow.

Position foam under bracket edge so that it is prop-

erly retained.

F22D0LA

2

1

1. Bracket edge

2. Foam

Rotate expansion pipe to position its T-fittings ver-

tically.

CAUTION: If T-fittings were not installed verti-

cally, water ingestion might occur when water-

craft tips over.

Tighten front clamp no. 2 as follows.

– Ensure to align expansion pipe with tuned pipe

so that their ends are in contact all around.

– Tighten clamp while maintaining expansion pipe

and tuned pipe together.

– Torqueclampto11N•m(97lbf•in).

– Ensure there is a gap between clamp ends.

Otherwise, try another clamp.

F22D0MA

A

A. Clamp ends must have a gap here

Ensure there is a gap between hose at front T-fit-

ting and fuel tank.

20 smr2004-3D

Loading...

Loading...