After dampening the leak sensor for a check purpose, completely wipe off

moisture. When wiping off moisture, do not press the leak sensor. When a sensor

unit touches a wall, the sensor sensitivity is lowered.

"4.5 Cleaning the Leak Tray" P.58

n Checking the gas sensor《GAS SENSOR CHECK》

Runs the gas sensor check.

Before the check, make the temperature become stable by 40 °C.

Heat up in the chamber so that ethanol may tend to volatilize.

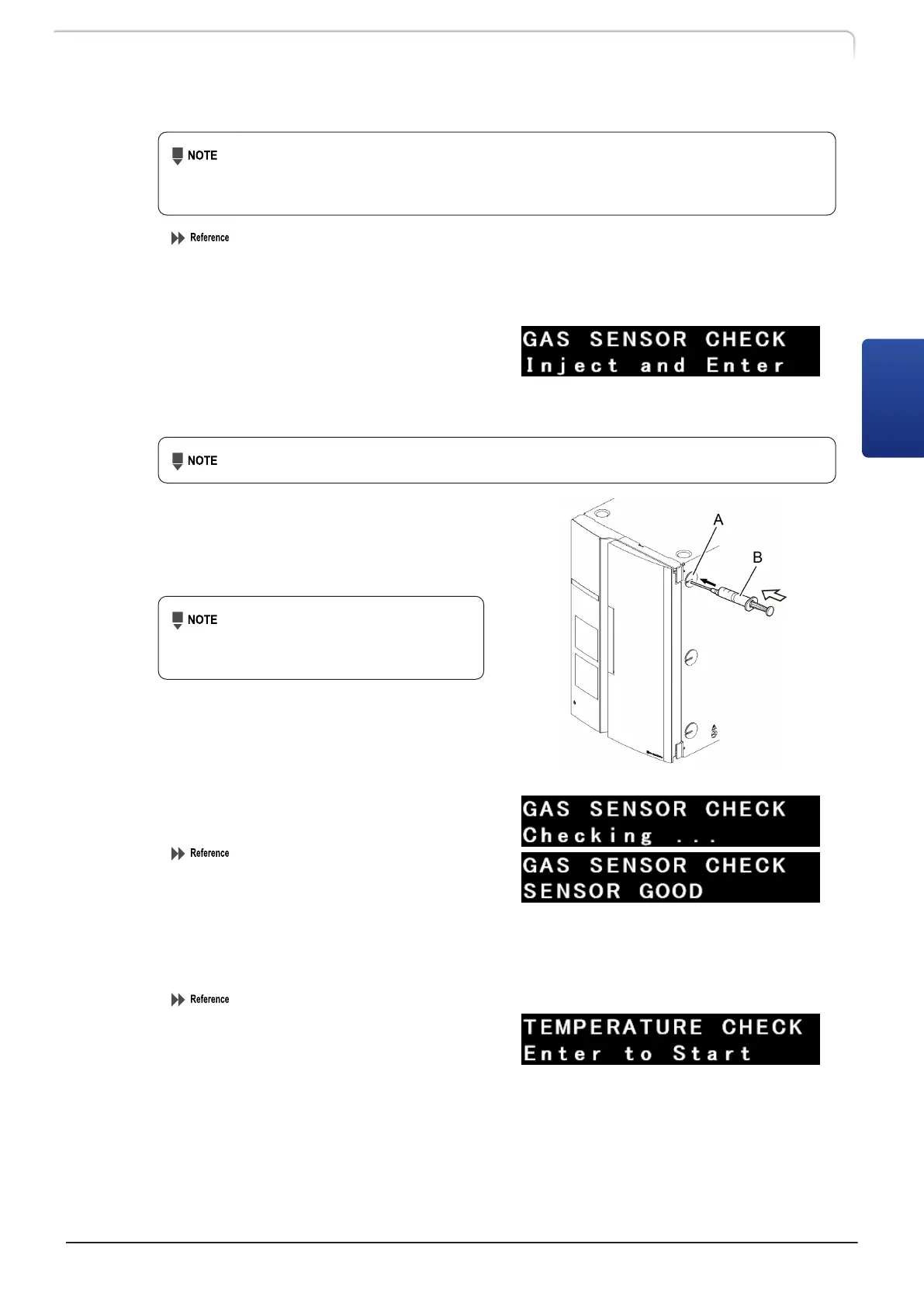

With the microsyringe (B), inject

approximately 100 µL of ethanol through

the tubing hole (A) on the upper part of

the right side.

Use

a micro syringe which has a

capacity of 100 µL (Part No.

670-12554-04 ,etc.).

Wait for approximately 30 seconds at

maximum. The diagnosis result is displayed.

In case of [NO GOOD], see

"4.3 Gas

Sensor Calibration" P.57.

n Checking the temperature control accuracy《TEMPERATURE CHECK》

System Guide "4 Hardware

Validation"

CTO-40C CL

37

3.5 VP Functions Screen

3

Loading...

Loading...