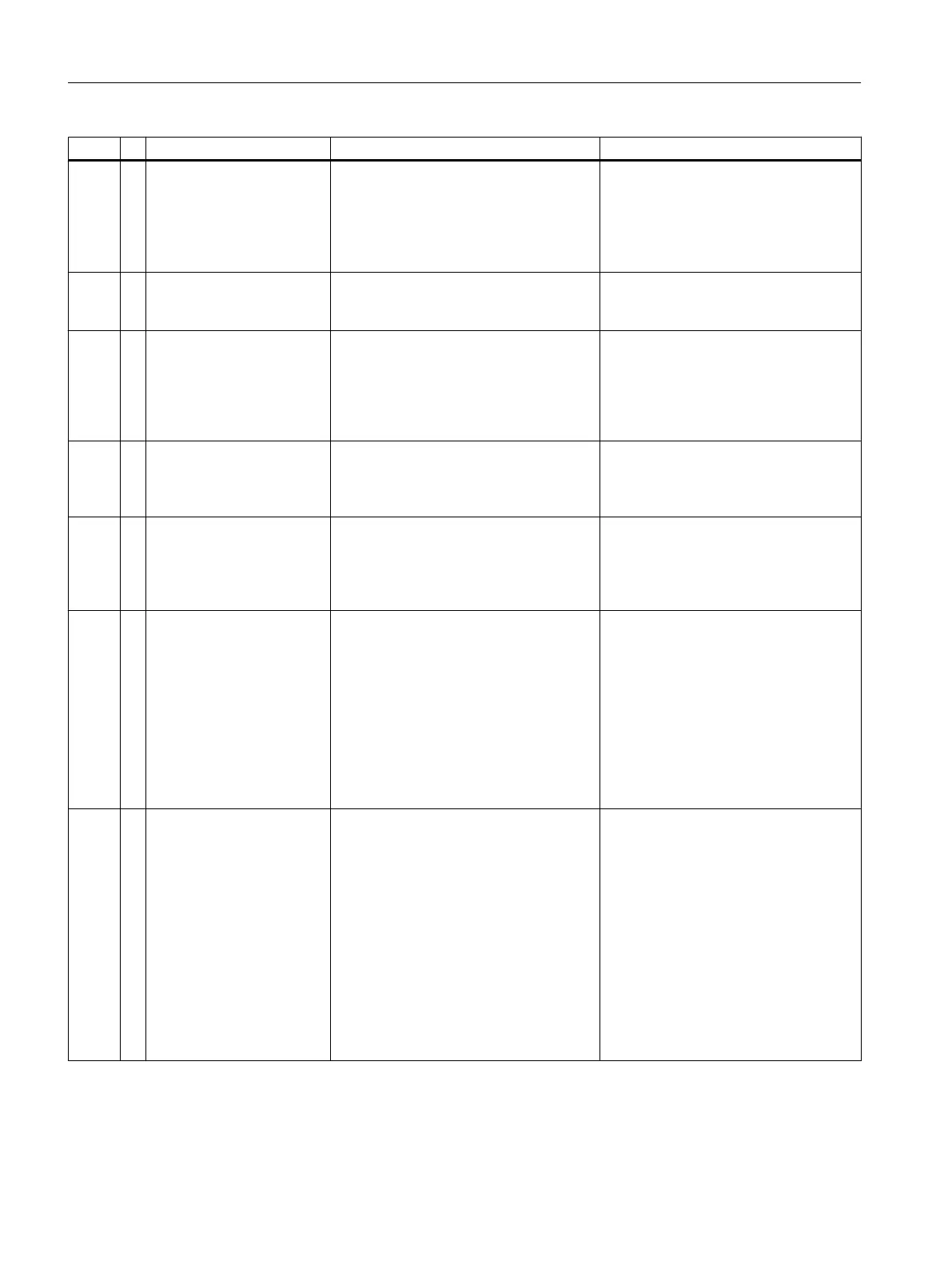

# Text Description Action

1084 + I2C Timeout on %4 All PICs: An I2C communication timeout

timer has expired. The timer is reset after

each successful character processed.

Only an addressed module may gener‐

ate a timeout. The timeout can occur on

incoming and outgoing characters.

Contact Customer Support.

1085 + I2C Read Past End on %4 All PICs: The I2C communication master

did not stop reading after the complete

response had been sent.

Contact Customer Support.

1086 + I2C Buffer Overflow on %4 All PICs: The combination of the transmit

and receive I2C message was too large,

causing a buffer overflow. (With kernel

revision 1: SSP_READ_UNEXPEC‐

TED_STOP, a stop condition occurred

before the end of the response).

Contact Customer Support.

1087 + I2C Write Past End on %4 All PICs: In an I2C message, more than

the number of bytes specified by the

length was written. The extra bytes are

ignored.

Contact Customer Support.

1088 + I2C Resync Error on %4 All PICs: Severe I2C error, causing the

current message to be dropped. Commu‐

nication will re-synchronize after the next

START or STOP condition. Usually as‐

sociated with alarm 1092.

Contact Customer Support.

1089 + I2C Write Unexpected Stop

on %4

All PICs: A new I2C message was re‐

ceived in the middle of a write. The old

message was discarded and the new

message is served (this message may

be out of sequence and therefore cause

other flags to be set).[With kernel revi‐

sion 1: SSP_WRITE_UNEXPEC‐

TED_STOP, during a slave write a stop

condition occurred before the message

was completed. The message is ignor‐

ed.]

Contact Customer Support.

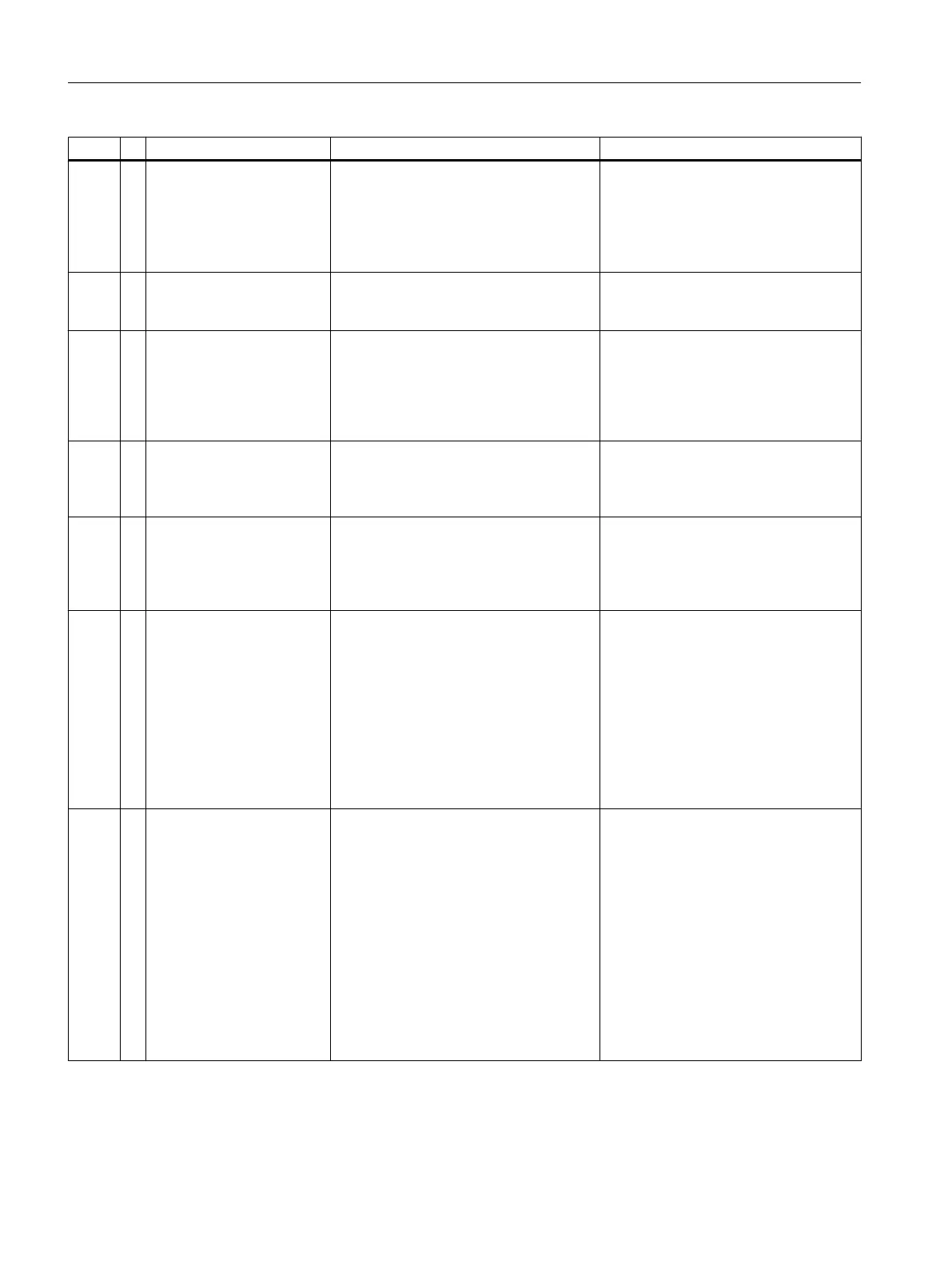

1090 + I2C Write Unexpected

Start on %4

All PICs: A new I2C message was re‐

ceived in the middle of a read. The old

message was discarded and the new

message is served (this message may

be out of sequence and therefore cause

other flags to be set). [With kernel revi‐

sion 1: SSP_WRITE_UNEXPEC‐

TED_START, during a slave write a Start

or Repeat Start (RS) condition was de‐

tected before the entire message was re‐

ceived (according to the length field). The

message is ignored and processing re‐

sumes following the Start or Repeat

Start.]

Contact Customer Support.

General Maintenance and Troubleshooting

4.6 Alarm Codes, Descriptions, and Suggested Actions

Maxum edition II Analyzer General Maintenance

50 Manual, August 2018, A5E42019842001

Loading...

Loading...