Installation and Startup

3-20

Startup

V

alues and Examples (continued)

Several

status words are provided to monitor the process operation,

determine if the cycle is complete, how it completed, or if something is

wrong. T

o take advantage of this information, display these words on your

operator interface and/or build a status table in TISOFT to monitor

locations. See T

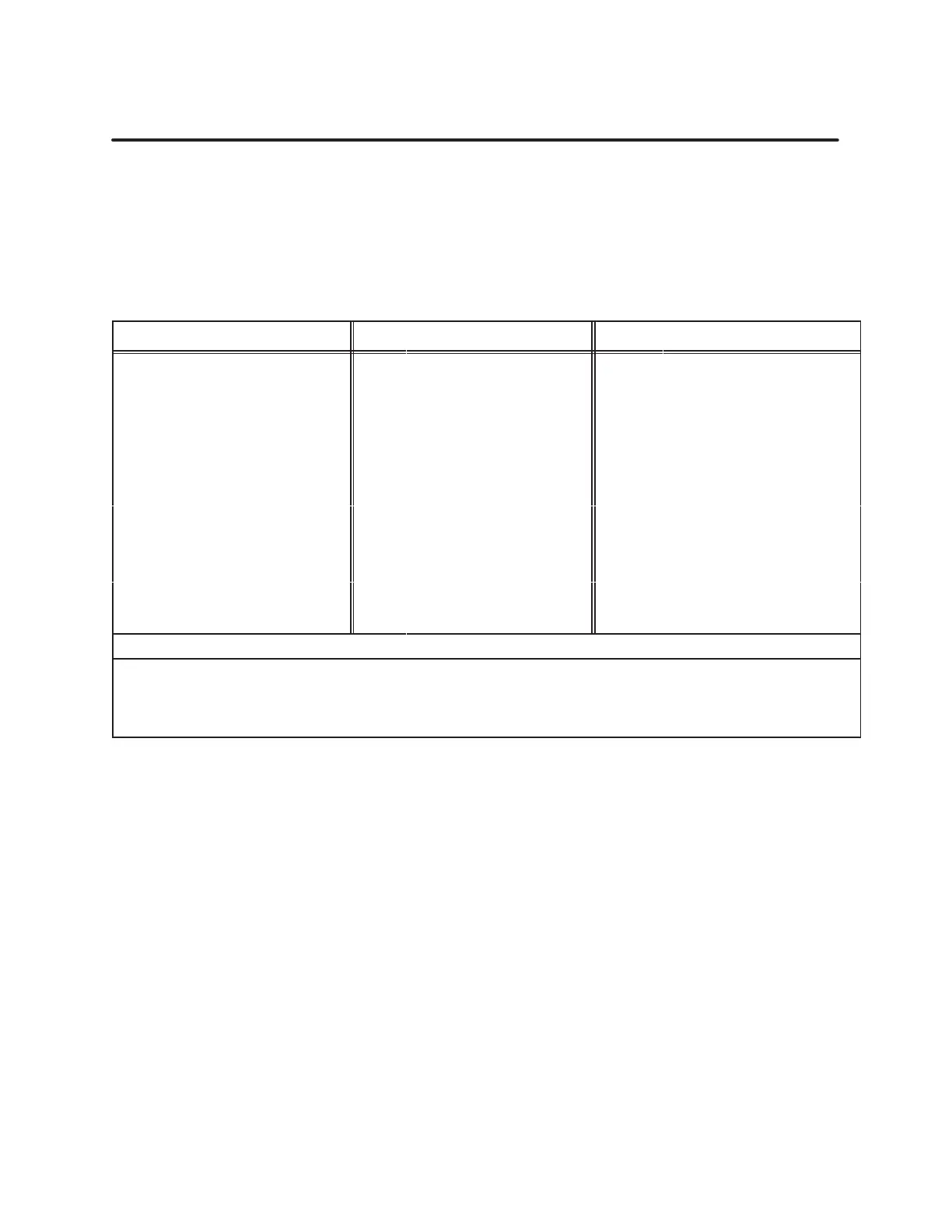

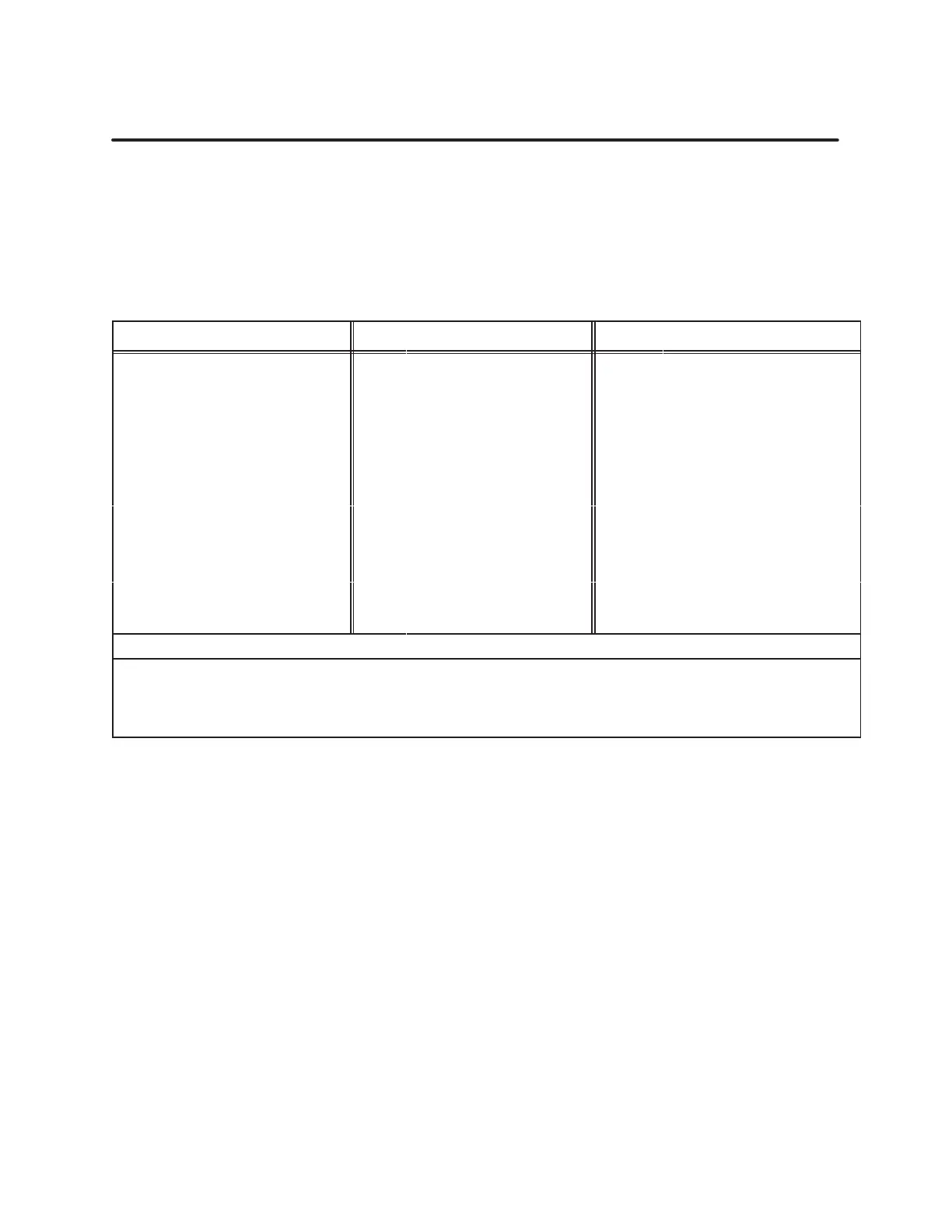

able 3-6.

T

able 3-6

Status W

ords

Location Description Location Description Location Description

WX1

→

Step

number

(D) V301

→

Scan time

(D) **V312

→

Close complete

(B)

WX2

→

Completes (B) V302

→

Clamp position

(D) **V313

→

Injection complete

(B)

*WX3

→

Errors (B) V303

→

Clamp velocity

(D) **V314

→

Pack complete

(B)

WX4

→

I/O channel

(D) V304

→

Clamp flow

(D) **V315

→

Plasticate complete

(B)

WY5

→

Download table

(D) V305

→

Clamp pressure

(D) **V316

→

Open complete

(B)

WY6

→

Upload table

(D) V306

→

Clamp pressure (D)

WY7

→

Run/Stop (D) V307

→

Ram position

(D)

WY8

→

Start Cycle

(B) V308

→

Ram velocity

(D)

V309

→

Ram flow

(D)

V310

→

Ram pressure

(D)

V311

→

Ram pressure

(D)

(D) = decimal display

(B) = binary display

* Be sure to check bits 3 and 4 of word WX3 for correct setting of dipswitches for your machine configuration before

attempting to run. See T

able 3-2 for setting details. It is recommended that a check for correct configuration is provided in

RLL that alarms if an incorrectly configured module is ever inserted into the base.

** V

alues in V312–V316 remain intact until the next time the same type profile is completed at which time they are

overwritten.

Loading...

Loading...