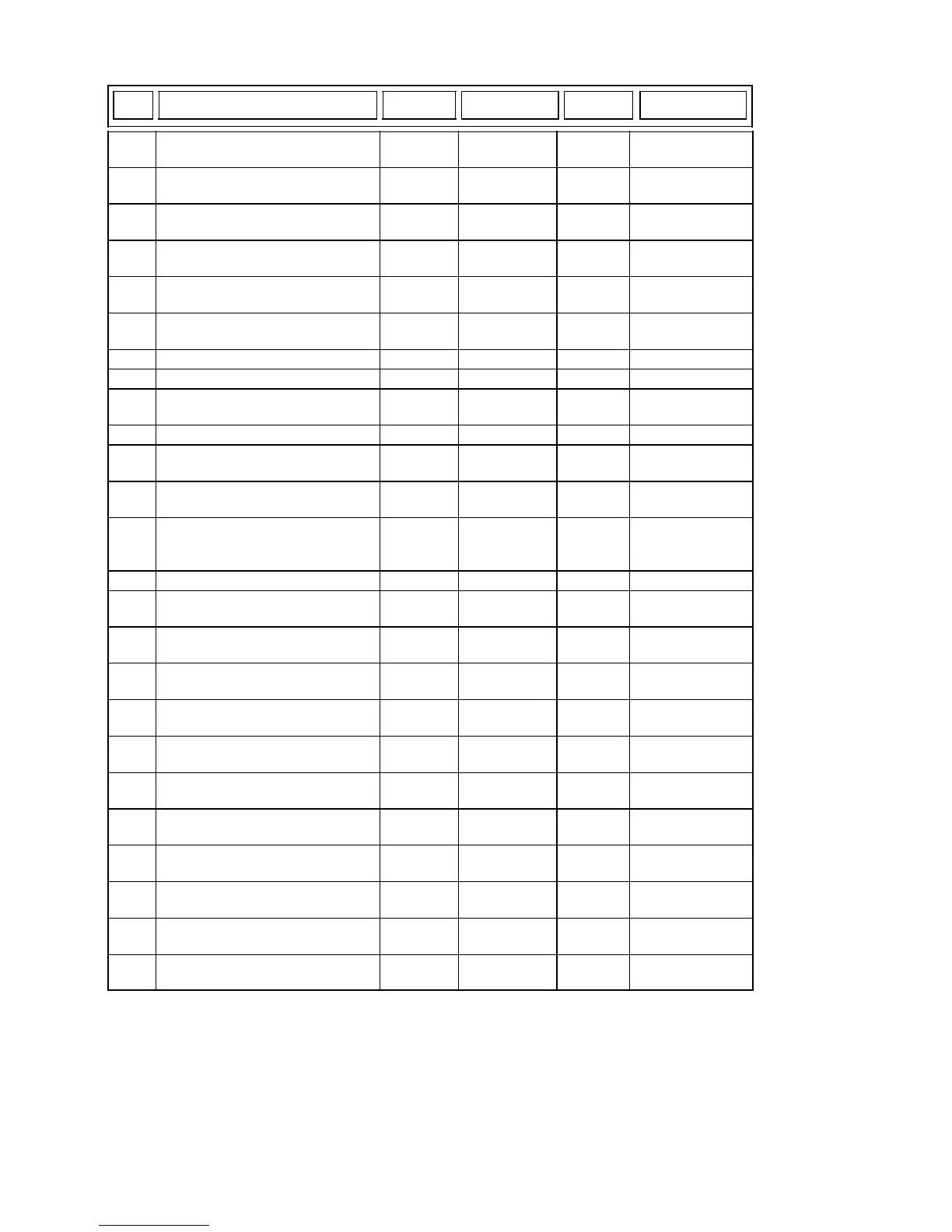

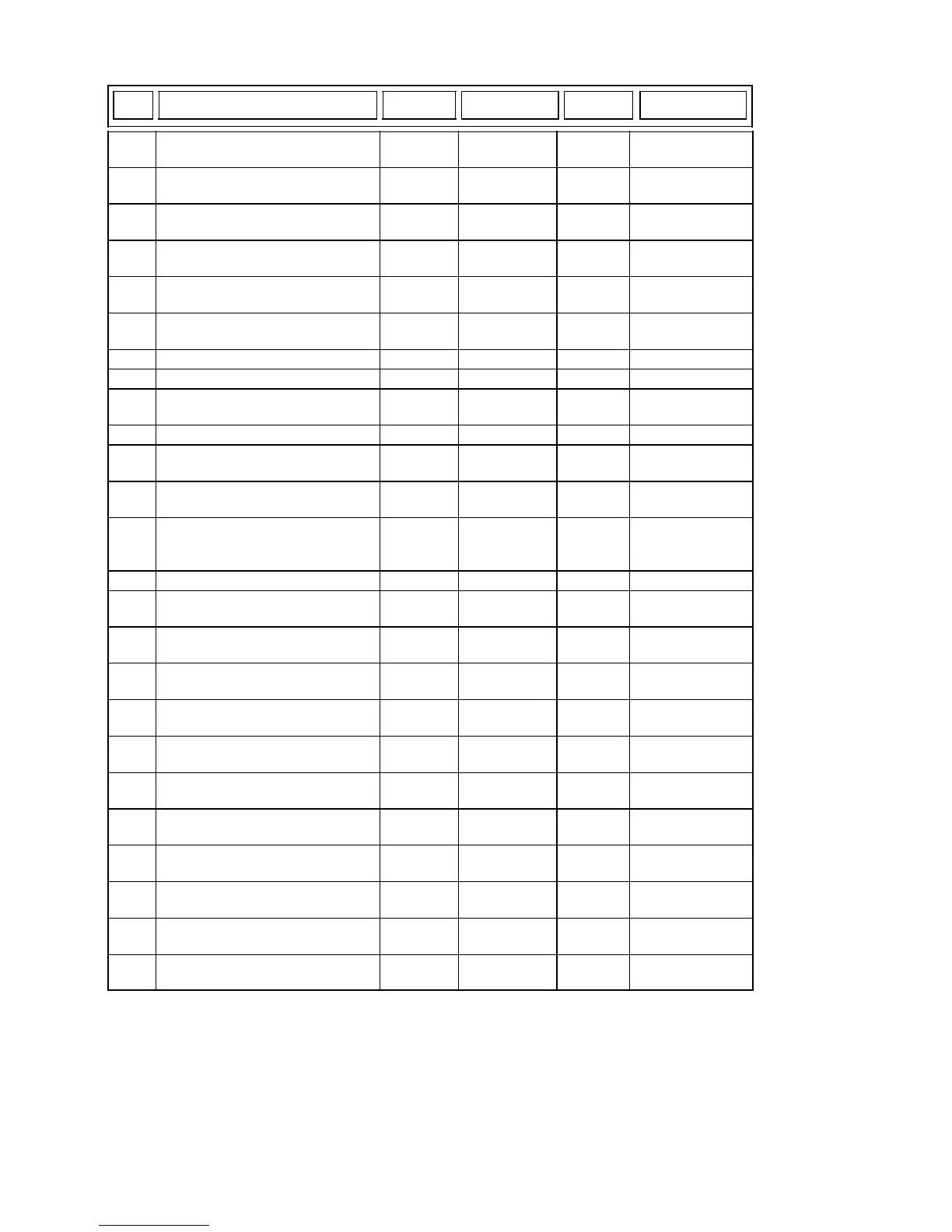

1 NC/Drive Machine Data 09.95

1.9.2 Axis-specific MD2

D e s i g n a t i o n

MD

No.

Standard

value

Maximum

input value

Reference

system

Input

unit

1324* Time const. symm. filt. rigid

tapping

1)

0 1 000 0.1ms

1328* K

v

factor 7th para. set 1 666 10 000

80 000

5)

--

0.01 s

-1

1332* K

v

factor 8th para. set 1 666 10 000

80 000

5)

--

0.01 s

-1

1336* Master for torque setpoint

coupling

4)

0 46 -- --

1340* Master for torque compensatory

control

4)

0 46 -- --

1344* Torque distribution torque

compensatory controller

4)

500 984 -- ‰

1364* 2nd compensation time const.

3)

150 9999 9999 -- 0.1 ms

1368* Learning rate

3)

100 500 -- %

1372* Measuring time 1

(for neural QEC only)

3)

600 9999 9999 % of MD 1236*

1376* Measuring time

3)

300 9999 9999 % of MD 1236*

1380* Measuring time 3

(for neural QEC only)

3)

200 9999 9999 % of MD 1236*

1384* Torque comp. controller

P component

4)

100 1 000 000 0.0001%

1388* 2nd measuring sys. connect.

1)

2)

5)

0

0

0

5 03 00 00

15 02 10 00

30 02 10 00

ANALOG

DIGITAL

DIGITAL

--

1392* Feedfw. ctrl. factor 8th p. set

3)

0 1 000 -- 0.1 %

1396* Position controller clock

frequency

1 64 --

Mult. of posit. controller's

basic clock frequency

1420*

2

)

P component compensatory

controller

0 16 000 -- 1

1424*

2

)

I component compensatory

controller

0 16 000 -- 1

1428*

2

)

D component compensatory

controller

0 16 000 -- 1

1432*

2

)

Time constant parallel model 6 000 16 000 -- 0.01 ms

1436*

2

)

Tolerance range synchronism

fine

40 16 000

99999999

5)

MS 1 units

1440*

2

)

Tolerance range synchronism

coarse

100 16 000

99999999

5)

MS 1 units

1444*

2

)

Emergency retraction threshold 400 16 000

99999999

5)

MS 1 units

1448*

2

)

Warning threshold n

max

and

a

max

90 100 -- %

1452*

2

)

Delay for controlled follow-up 16 000 16 000 -- 1 ms

1456*

2

)

Default link type 0 3

4

3)

-- --

_______

1) SW 2 and higher

2) SW 3 and higher

3) SW 4 and higher

4) SW 4.4 and higher

5) SW 5 and higher

1–38 © Siemens AG 1992 All Rights Reserved 6FC5197- AA60

SINUMERIK 840C (IA)

Loading...

Loading...